Best Material for Dehumidifier Heat Exchangers: Copper vs. Aluminum

I always look for the best material when choosing heat exchangers for dehumidifiers. Copper stands out for its excellent Heat Transfer, durability, and resistance to corrosion. Recent studies show that material choice impacts both energy efficiency and lifespan. For example:

| Study / Author | Material | Performance | Lifespan Impact |

|---|---|---|---|

| Ge et al. | Aluminium-based MOFs | 2–3× higher dehumidification at 70% RH | Implied longer operational life |

I find that a Copper Fin Heat Exchanger often delivers the reliability and performance I need.

Key Takeaways

- Copper heat exchangers offer superior heat transfer, durability, and corrosion resistance, making them ideal for high-performance and long-lasting dehumidifiers.

- Aluminum heat exchangers are lightweight and cost-effective, suitable for portable or budget-friendly dehumidifiers where weight and price matter most.

- Choosing the right material depends on your priorities: select copper for efficiency and durability, or aluminum for affordability and ease of installation.

Quick Comparison Summary

Copper vs. Aluminum at a Glance

When I compare copper and aluminum for dehumidifier heat exchangers, I focus on several key factors. Copper offers excellent thermal conductivity, which means it transfers heat more efficiently. I notice that copper also resists corrosion better, especially in humid environments. This makes it a reliable choice for long-term use. Aluminum, on the other hand, stands out for its lightweight nature and lower cost. I find that manufacturers often choose aluminum when they want to reduce the overall weight of the unit or keep production costs down.

Tip: I always consider the specific application before choosing a material. For high-performance and durability, copper usually wins. For budget-friendly or portable designs, aluminum can be a smart option.

Key Pros and Cons Table

Here’s a quick table I use to compare the two materials:

| Feature | Copper | Aluminum |

|---|---|---|

| Heat Transfer | Excellent | Good |

| Corrosion Resistance | High | Moderate |

| Durability | Superior | Good |

| Weight | Heavier | Lightweight |

| Cost | Higher | Lower |

| Maintenance | Easier to repair | More challenging to repair |

| Application Suitability | Best for demanding environments | Ideal for cost-sensitive projects |

I rely on this summary when I advise clients or make decisions for my own projects. The right choice depends on the priorities—performance, cost, or ease of handling. Brands like senjun provide both copper and aluminum options, so I can always find a solution that fits my needs.

Heat Transfer Efficiency

Copper’s Performance in Dehumidifiers

When I select A Heat Exchanger for a dehumidifier, I always consider how well it transfers heat. Copper stands out because of its superior thermal conductivity. This property allows copper to move heat quickly from one side of the exchanger to the other. In my experience, this efficiency means the dehumidifier can remove moisture from the air faster and with less energy.

I have noticed that copper maintains its performance even after long periods of use. The heat transfer coefficient for copper-fin evaporators decreases by only about 7.1% to 19.5% during intermittent operation. This stability ensures that the dehumidifier continues to work efficiently over time. In contrast, other materials often lose more of their effectiveness as they age.

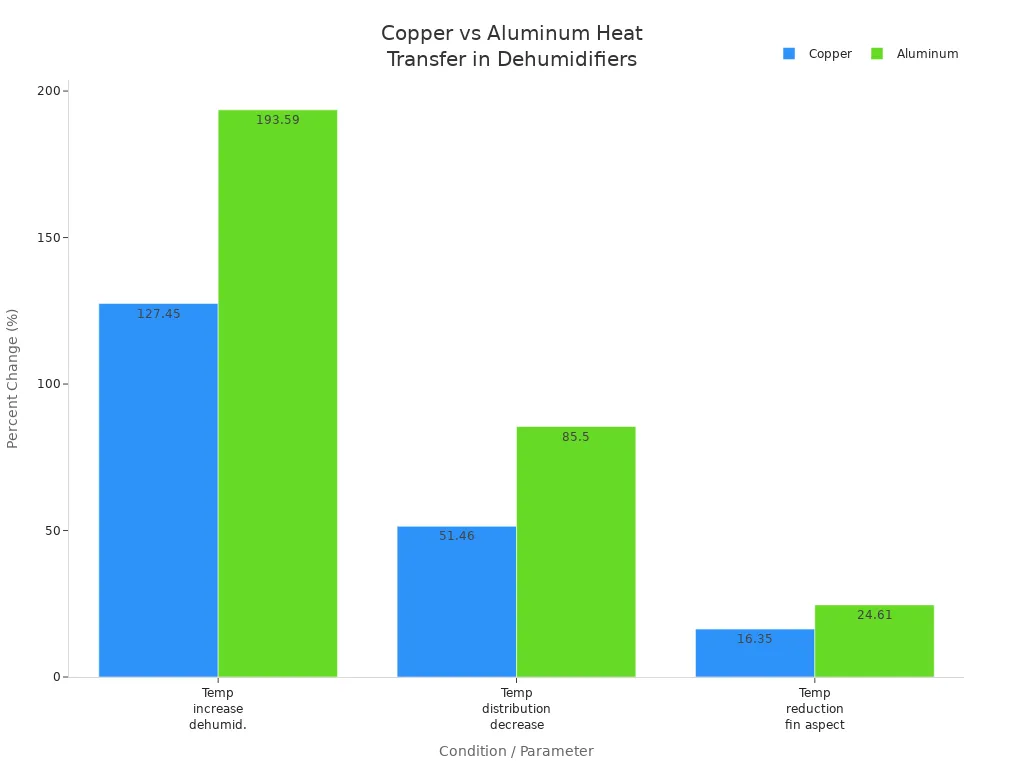

Here is a table that highlights the differences in thermal performance between copper and aluminum under various dehumidification conditions:

| Parameter / Condition | Copper | Aluminum |

|---|---|---|

| Thermal conductivity impact | Superior thermal conductivity | Lower thermal conductivity |

| Temperature increase during dehumidification | +127.45% | +193.59% |

| Temperature distribution decrease with 66.66% RH increase | 51.46% decrease | 85.5% decrease |

| Temperature reduction with 200% fin profile aspect ratio increase | 16.35% decrease | 24.61% decrease |

I find that copper’s ability to maintain a more stable temperature distribution is critical for consistent dehumidification. The Copper Fin Heat Exchanger, for example, delivers reliable performance in both residential and commercial settings.

I also pay attention to how heat transfer efficiency affects energy consumption. More efficient copper heat exchangers minimize temperature differences, which improves overall system performance. When I use a well-designed copper heat exchanger, I see a noticeable reduction in energy use. Features like microchannel structures and direct desiccant coatings on copper surfaces further enhance heat and moisture transfer. These improvements can boost dehumidification capacity to around 1.59 to 2.0 kg/h, with thermal performance coefficients above 2.0. This means the dehumidifier uses energy more effectively, saving on operational costs.

Note: Copper-based microchannel heat exchangers not only improve heat transfer but also maintain their efficiency over time, making them a smart investment for long-term use.

Aluminum’s Performance in Dehumidifiers

Aluminum offers some advantages, especially when weight and cost are important. However, I have observed that aluminum heat exchangers do not match copper in terms of heat transfer efficiency. The heat transfer coefficient for aluminum-fin evaporators drops by about 10.1% to 36.6% during intermittent operation. This greater decline means that aluminum exchangers may lose efficiency faster, especially in demanding environments.

Aluminum’s lower thermal conductivity also affects its ability to maintain stable temperature distribution. When humidity rises, the temperature distribution in aluminum exchangers can decrease by as much as 85.5%. This makes it harder for the dehumidifier to keep up with changing conditions.

I find that thermal contact resistance and hydrophilicity degradation impact aluminum more than copper. Over time, these factors can further reduce the heat transfer performance of aluminum exchangers.

Here is a visual comparison of heat transfer coefficients for copper and aluminum under different dehumidifier conditions:

Despite these challenges, aluminum still plays a role in applications where weight and initial cost take priority over long-term efficiency. I recommend aluminum for portable or budget-friendly dehumidifiers, but I always weigh these benefits against the potential for faster performance loss.

Cost Considerations

Material and Manufacturing Costs

When I evaluate heat exchanger materials, I always look at the initial costs. Copper usually costs more than aluminum. The price of copper fluctuates, but it often remains higher per kilogram. Aluminum, on the other hand, offers a more budget-friendly option. Manufacturers can shape aluminum more easily, which reduces production time and labor costs.

Here is a quick comparison:

| Aspect | Copper | Aluminum |

|---|---|---|

| Raw Material Price | Higher | Lower |

| Manufacturing Ease | Moderate | High |

| Production Cost | Higher | Lower |

I find that brands like senjun can offer both copper and aluminum heat exchangers, which helps me choose based on my project’s budget. If I need to keep costs down, I often select aluminum. For projects where performance matters most, I invest in copper.

Tip: I always check the latest market prices before making a decision. Material costs can change quickly.

Long-Term Value and Investment

While aluminum saves money upfront, I have learned that copper often delivers better value over time. Copper heat exchangers last longer and resist corrosion better. This means I spend less on repairs and replacements. In humid environments, copper’s durability really stands out.

I also consider energy savings. Copper’s superior heat transfer reduces energy use, which lowers utility bills. Over several years, these savings add up. When I look at the total cost of ownership, copper often proves to be the smarter investment.

If I want a heat exchanger that performs well for many years, I choose copper. For short-term or lightweight applications, aluminum remains a solid choice. Senjun’s range of products lets me match the right material to my needs and budget.

Durability and Corrosion Resistance

Copper’s Durability and Corrosion Profile

When I choose a heat exchanger for a dehumidifier, I always look for materials that can withstand harsh conditions over time. Copper stands out for its impressive durability and resistance to corrosion. In my experience, copper heat exchangers maintain their structural integrity even when exposed to high humidity and airborne contaminants. I have seen studies where copper surfaces show much lower microbial contamination than aluminum. For example, fungal concentrations on copper average less than 1 CFU/cm², while aluminum can reach thousands of CFU/cm². This low microbial colonization means copper resists biofilm formation and microbial-induced corrosion, which often occur in moist, contaminated environments.

I also value copper’s performance in environments with volatile organic acids, such as acetic and formic acid. Experimental research using electrical resistance sensors shows that copper corrosion rates remain low, even at relative humidity levels up to 60%. Unlike iron, which corrodes quickly under these conditions, copper barely reacts, making it ideal for indoor environments with moderate to high humidity and organic contaminants. This stability gives me confidence that a Copper Fin Heat Exchanger will last for years without significant degradation.

Here are some reasons I rely on copper for long-term performance in dehumidifiers:

- Copper’s high thermal conductivity ensures efficient and consistent heat transfer.

- Its corrosion resistance allows it to withstand moisture and chemical exposure, preventing early failure.

- The malleability of copper supports compact, durable coil designs.

- Copper’s strength and repairability help it maintain reliable operation under pressure and in harsh conditions.

These qualities make copper heat exchangers a smart investment for anyone seeking efficiency and reliability over the long term.

Aluminum’s Durability and Corrosion Profile

Aluminum also plays a significant role in heat exchanger design, especially when weight and corrosion resistance are priorities. I have found that aluminum heat exchangers are lighter than copper, which makes them easier to handle and install. In environments where corrosive agents are present, aluminum’s natural oxide layer provides a protective barrier, helping it resist wear and extend its lifespan.

From my experience, aluminum’s corrosion resistance gives it an advantage in certain applications, especially where exposure to aggressive chemicals or salty air is common. Aluminum condensers tend to last longer in these settings because the oxide layer shields the metal from further attack. However, aluminum does not match copper’s thermal conductivity, and it can be more challenging to repair if damaged.

I have also reviewed studies comparing aluminum, copper, and composite tubes. While aluminum performs well in both heating and cooling modes, its lower thermal conductivity means it may not transfer heat as efficiently as copper. During manufacturing, aluminum-copper composite tubes can experience wear, but this is usually controlled to avoid severe damage. Although direct comparisons of physical damage resistance are limited, I have noticed that aluminum resists corrosion-related wear better, while copper’s repairability gives it an edge in durability after physical impacts.

Weight and Handling

Impact on Design and Installation

When I select a heat exchanger for a dehumidifier, I always consider how weight affects the overall design. Copper heat exchangers feel heavier in my hands. This extra weight can add stability to stationary units, but it also means I need stronger support structures during installation. Aluminum, on the other hand, feels much lighter. I find that this makes the installation process easier, especially in ceiling-mounted or wall-mounted dehumidifiers. Lighter components reduce strain on mounting brackets and allow for more flexible placement.

Manufacturers like senjun use advanced manufacturing techniques to optimize the weight of both copper and aluminum heat exchangers. I have seen that lighter units often require less labor and time to install. This can lower installation costs and speed up project timelines. For large-scale commercial projects, I prefer lighter aluminum options when I need to install multiple units quickly.

Portability and Application

Weight plays a critical role in the portability of dehumidifiers. I notice that lightweight heat exchanger components, such as thermoelectric modules (TEMs) and heat sink fans, make portable dehumidifiers possible. These components operate quietly and efficiently, which suits noise-sensitive environments like libraries or bedrooms.

Here is a table that summarizes how weight influences portability and application:

| Factor | Evidence Summary | Implication on Portability and Application |

|---|---|---|

| Lightweight Thermoelectric Modules (TEMs) | TEMs are very light and compact compared to conventional components. | Enhances portability, making TEDs suitable for small-scale and portable use. |

| Heat Exchanger Components Weight | Lightweight heat sink fans and TEMs contribute to smooth, clean, and quiet operation without moving parts. | Enables use in noise-sensitive and eco-friendly environments. |

| Efficiency (Coefficient of Performance) | TEDs have lower COP compared to vapor compression systems. | Limits TEDs to small and portable devices, restricting large-scale applications. |

| Power Source Compatibility | TEMs and heat sink fans can be powered by DC input, including solar power. | Broadens application to solar-powered portable water generation and off-grid use. |

I recommend lightweight aluminum heat exchangers for portable or off-grid dehumidifiers. For stationary or high-capacity systems, I choose copper for its durability and performance. Senjun’s expertise in both materials allows me to match the right product to each application.

Maintenance and Repairability

Ease of Maintenance

When I maintain dehumidifier heat exchangers, I always look for materials that simplify the process. Copper heat exchangers stand out because I can clean and inspect them easily. The smooth surface of copper resists buildup, so I spend less time removing dust or debris. I also find that copper’s durability allows me to use standard cleaning tools without worrying about damaging the coils.

Aluminum heat exchangers require a bit more care. The lighter construction means I must handle them gently to avoid bending the fins. I often use a soft brush or compressed air to clean aluminum surfaces. If I notice any corrosion or discoloration, I address it quickly to prevent further damage. Brands like senjun design their products for easy access, which helps me perform routine maintenance efficiently.

Tip: Regular cleaning and inspection extend the life of any heat exchanger. I recommend checking for signs of corrosion or leaks at least twice a year.

Repair Options and Longevity

Over the years, I have encountered several common repair issues with both copper and aluminum heat exchangers in dehumidifiers:

- Corrosion of aluminum pipes from acidic oils can damage the heat exchanger and lead to compressor failure.

- Micro cracks at soldered joints, often from manufacturing processes, may cause refrigerant leaks.

- Coil freezing from partial refrigerant loss can result in compressor overheating.

- Manufacturing defects, such as welding problems or inconsistent tube expansion, sometimes cause early failures.

- Repairs can become uneconomical for older or lower-quality units, making replacement a better option.

- Second-hand dehumidifiers with heat exchanger problems rarely offer reliable performance unless the issue is electrical.

I always weigh the cost of repair against the age and quality of the unit. For high-quality products, especially those from reputable manufacturers like senjun, repairs often make sense and extend the lifespan of the equipment. For older or budget models, replacement may be the smarter choice.

Application Suitability

Residential Dehumidifiers

When I select a heat exchanger for a residential dehumidifier, I focus on efficiency and cost. I have seen that the structure of the evaporator—such as the type of fins and tube diameter—plays a big role in performance. Research on heat pump drying systems shows that different fin designs, like vortex-generating or corrugated fins, can improve heat transfer and airflow. These design choices help boost dehumidification, especially in low-temperature, high-humidity environments. While these studies do not directly compare copper and aluminum for residential use, they highlight how structural factors can influence both efficiency and cost.

I also pay attention to new technologies. Desiccant-coated heat exchangers, especially those using silica gel, stand out for their high efficiency. These systems can achieve a coefficient of performance (COP) up to 7, which is nearly double that of traditional systems. Energy savings can reach almost 19%. I find that aluminum fumarate MOF-coated heat exchangers are gaining attention for specialized uses. For most homes, I recommend choosing a heat exchanger that balances advanced design with proven materials. Brands like senjun offer both copper and aluminum options, so I can match the right product to each home’s needs.

Commercial and Industrial Use

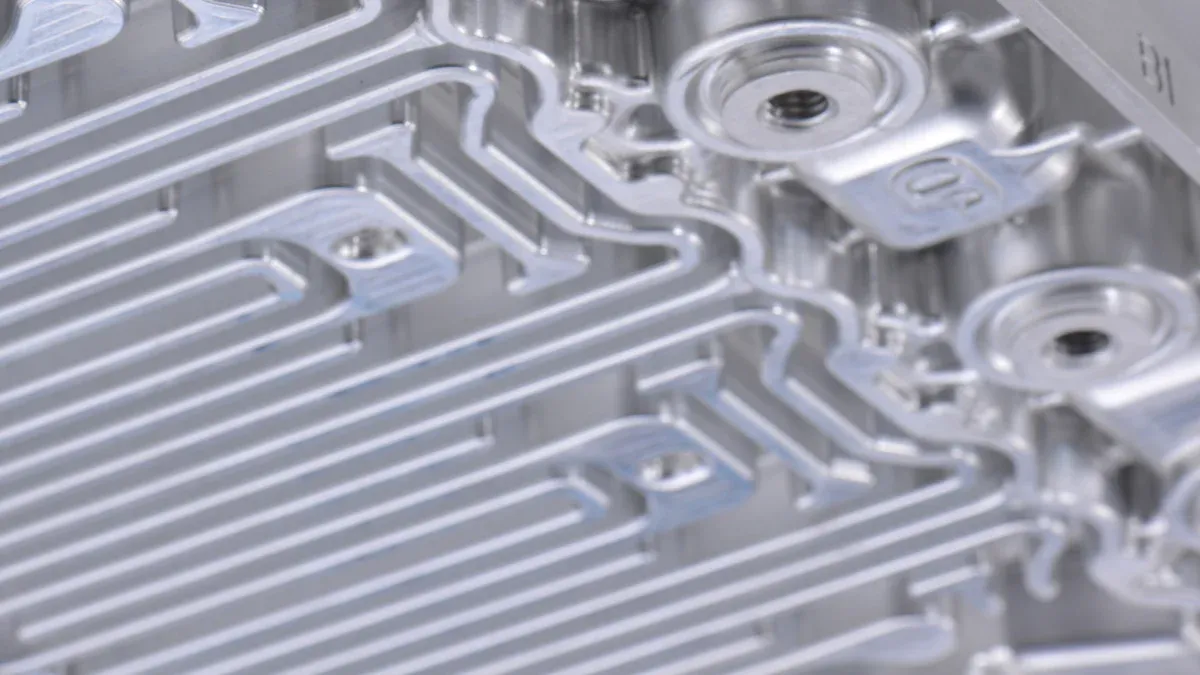

In commercial and industrial settings, I always prioritize durability and reliability. Industry reports show that most commercial dehumidifiers use copper pipes with a minimum thickness of 0.5 mm, paired with hydrophilic membrane corrugated aluminum fins. This combination ensures strong heat transfer and long service life. The cabinet often uses aluminum alloy for its strength and corrosion resistance. Double insulation with high-density polyurethane adds soundproofing and fire protection.

I have followed research collaborations between industry leaders and organizations like the Copper Development Association. These teams work to optimize copper tube and aluminum fin heat exchangers for both standard and low-temperature conditions. Their goal is to prevent frost and maximize efficiency. I trust brands like senjun, which use these advanced designs, to deliver reliable performance in demanding environments. For factories, warehouses, or large public spaces, I always recommend heat exchangers built with these robust materials and thoughtful engineering.

Copper Fin Heat Exchanger in Dehumidifiers

When I choose a dehumidifier for demanding environments, I often rely on a Copper Fin Heat Exchanger. This design brings several performance advantages that I have seen firsthand:

- Fins on copper tubing increase the surface area, which allows more heat to transfer between the pipe and the surrounding air.

- Improved air contact from the finned design boosts heat transfer efficiency, especially in air-cooled systems.

- Copper’s excellent thermal conductivity enables faster and more efficient heat exchange, which means the dehumidifier removes moisture quickly.

- The durability of copper finned pipes ensures reliable operation, even after long hours in harsh or humid conditions.

- High-efficiency heat exchangers help reduce energy consumption, saving money and lowering the carbon footprint.

- Copper’s high corrosion resistance supports long-term reliability, even in environments with high humidity or airborne contaminants.

- The recyclable nature of copper aligns with sustainability goals, making it a responsible choice for manufacturers and users.

I also pay close attention to maintenance and operational costs. In my experience, a Copper Fin Heat Exchanger usually requires little maintenance because of its simple structure and strong fin-to-tube connections. However, I have noticed that high fin density can make cleaning more difficult due to dust buildup. When I select a model with wider fin spacing, I find it easier to clean and maintain.

Here’s a quick comparison of copper and aluminum fin heat exchangers:

| Attribute | Copper Fin Heat Exchangers | Aluminum Fin Heat Exchangers |

|---|---|---|

| Cost | Higher initial material cost | More affordable upfront |

| Thermal Conductivity | Excellent, leading to better heat transfer | Good, but lower than copper |

| Durability | Highly durable, moderate corrosion resistance | Strong, better corrosion resistance with coatings |

| Maintenance | Generally low due to durability | Potentially lower if coated |

| Applications | High-efficiency systems | Budget-conscious or corrosive environments |

I recommend a Copper Fin Heat Exchanger for anyone who values efficiency, durability, and long-term savings in their dehumidifier.

About senjun and Its Role in Heat Exchanger Manufacturing

When I look for reliable heat exchanger manufacturers, I always pay close attention to the company’s background and expertise. Ningbo Senjun New Materials Co., Ltd., or senjun, stands out in the industry. I have seen how senjun commits to research, development, and production of high-quality heat exchangers. The company focuses on wire tube condensers and copper aluminum fin heat exchangers. These products serve a wide range of applications, including refrigerators, freezers, drinking fountains, display cabinets, wine cabinets, medical ultra-low temperature refrigerators, ice makers, and dehumidifiers.

In my experience, senjun’s dedication to innovation ensures that their heat exchangers meet strict performance and durability standards.

I trust senjun because the company invests in advanced manufacturing processes. Their engineering team uses modern techniques to optimize both copper and aluminum heat exchangers. I have noticed that senjun’s products deliver consistent results in both residential and commercial environments.

Here are some reasons why I recommend senjun for heat exchanger solutions:

- Broad product range for various industries

- Strong focus on research and development

- Proven track record in delivering reliable, efficient products

- Ability to customize solutions for unique project needs

I believe that senjun’s expertise and commitment to quality make it a top choice for anyone seeking high-performance heat exchangers for dehumidifiers or other demanding applications.

When I choose a dehumidifier heat exchanger, I weigh my priorities.

- I select copper for top performance and durability, especially with a Copper Fin Heat Exchanger.

- I pick aluminum when cost or weight matters most.

- I trust brands like senjun for advanced solutions in both materials.

FAQ

What makes copper heat exchangers better for dehumidifiers?

I choose copper for its excellent heat transfer, strong durability, and high corrosion resistance. These qualities help dehumidifiers run efficiently and last longer.

Are aluminum heat exchangers a good choice for portable dehumidifiers?

Yes, I often select aluminum for portable units. Aluminum is lightweight and affordable, making it ideal for smaller, easy-to-move dehumidifiers.

Does senjun offer both copper and aluminum heat exchangers?

I trust senjun because they manufacture both copper and aluminum heat exchangers. This lets me pick the best material for each specific application.