Top China Suppliers of Industrial Shell and Tube Heat Exchangers

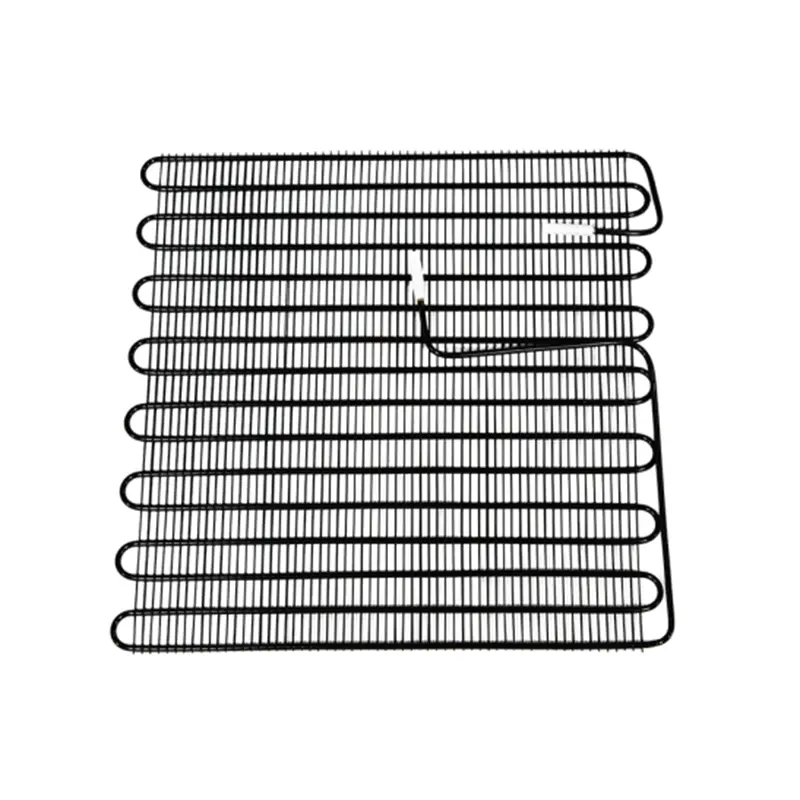

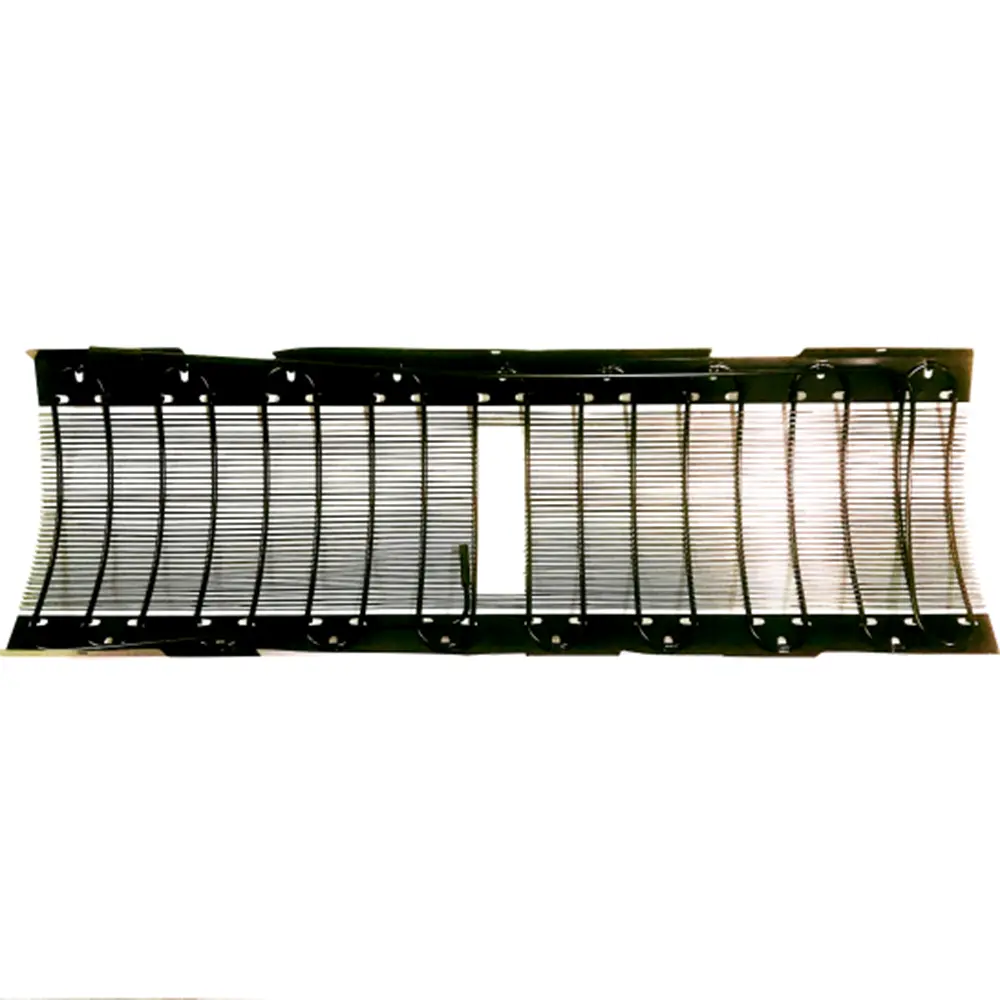

The Industrial Shell and Tube Heat Exchanger from Ningbo Senjun New Materials Co., Ltd. is designed for optimal thermal efficiency in various industrial applications. Engineering excellence ensures that these heat exchangers provide superior heat transfer performance, making them ideal for processes requiring precise temperature control, Crafted from high-quality materials, our shell and tube heat exchangers are built to withstand demanding conditions while offering longevity and reliability. They feature customizable designs to accommodate diverse operational requirements, enabling businesses to enhance productivity while minimizing energy consumption, Ningbo Senjun prioritizes innovation and quality, ensuring that each heat exchanger undergoes rigorous testing and quality checks. This commitment to excellence guarantees that our clients receive products that meet international standards and exceed expectations, Choose the Industrial Shell and Tube Heat Exchanger for a reliable, efficient solution that adapts to your industry needs. Streamline your thermal management processes and achieve better performance with our state-of-the-art technology and expertise

How To Decide Between Industrial Shell And Tube Heat Exchanger Market Leader From Concept to Delivery

When it comes to selecting the right industrial shell and tube heat exchanger, global buyers often face a significant decision-making process. At Ningbo Senjun New Materials Co., Ltd., we understand that the choice between various market leaders hinges on several vital factors—from concept to delivery. Founded in 2010, our company specializes in wire tube condensers and copper aluminum fin heat exchangers, catering to various applications like refrigerators, freezers, drinking fountains, and display cabinets. The first step in your decision process is to assess the specific requirements of your application. Consider factors such as thermal efficiency, compatibility with fluids, space constraints, and maintenance capabilities. Evaluating how these factors align with the products offered by different manufacturers will help narrow down your options. At Senjun, we pride ourselves on our innovative designs and commitment to quality, ensuring that our products not only meet but exceed industry standards. Lastly, consider the reliability of the supplier in terms of delivery timelines and after-sales support. A robust partnership with a manufacturer who values punctuality and customer service can significantly impact your operational efficiency. With over a decade of expertise, Ningbo Senjun New Materials Co., Ltd. is well-equipped to deliver not just high-quality products but also comprehensive support, ensuring that your transition from concept to delivery is seamless and successful. Choose wisely, and let us help you enhance your operational performance.

How To Decide Between Industrial Shell And Tube Heat Exchanger Market Leader From Concept to Delivery

| Dimension | Value | Importance (1-5) |

|---|---|---|

| Heat Transfer Efficiency | 85-90% | 5 |

| Maintenance Frequency | Annual | 4 |

| Material Options | Stainless Steel, Copper | 3 |

| Max Pressure (bar) | 20 | 5 |

| Operating Temperature (°C) | -10 to 200 | 5 |

| Cost Estimate ($) | $10,000 - $50,000 | 4 |

| Lead Time (Weeks) | 6-12 | 3 |

Curated Selection of Industrial Shell And Tube Heat Exchanger Pioneers in the Field Custom Solutions,

R

Ryan Turner

I’m very satisfied! The item quality is great, and the after-sales service was attentive and professional.

23 June 2025

E

Ethan Nelson

Quality product with a great finish! The support staff were professional and willing to help.

13 June 2025

A

Avery Hughes

This product is simply outstanding! Great quality and superb service from the support team.

13 June 2025

M

Maddison Reed

Fantastic quality and superb support! The after-sales team really knows their stuff.

15 June 2025

M

Michael Perez

Incredible quality and service! The support team was friendly and efficient.

27 May 2025

O

Olivia Moore

Very pleased with my purchase! The product quality is great, and the customer service was exemplary.

09 June 2025