Wholesale Industrial Refrigeration Cycle Manufacturers & Factories

As a key player in the industrial refrigeration sector, I understand the importance of efficiency and reliability in Cooling Systems. Our offerings include advanced industrial refrigeration cycle solutions, tailored to meet the specific needs of various industries. As a trusted supplier based in China, we take pride in our role as manufacturers dedicated to quality and innovation, At Ningbo Senjun New Materials Co., Ltd., we focus on providing exceptional products that enhance productivity while maintaining energy efficiency. Our refrigeration systems are designed to operate seamlessly, ensuring optimal temperature control and longevity. Our team works closely with clients to customize solutions that fit their unique requirements, whether they’re looking for large-scale installations or smaller setups, Choosing us means partnering with experienced manufacturers who prioritize your business needs and satisfaction. Let’s collaborate to keep your operations running smoothly and effectively with our cutting-edge refrigeration technology

10 tips Industrial Refrigeration Cycle Manufacturers Where Innovation Meets 2025 Exceeds Industry Benchmarks

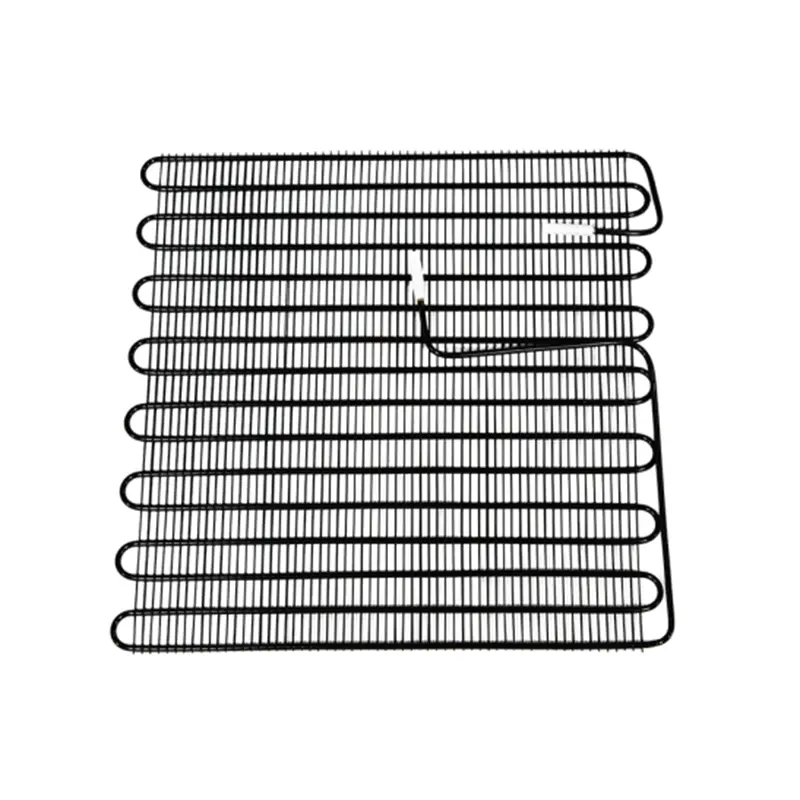

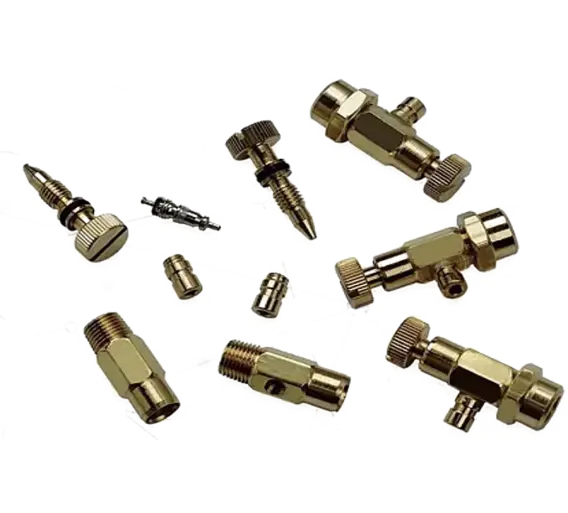

In the rapidly evolving landscape of industrial refrigeration, manufacturers are stepping up innovation to meet the challenges of 2025 and beyond. At Ningbo Senjun New Materials Co., Ltd., we recognize that our commitment to research and development is not just an operational goal, but a necessity in exceeding industry benchmarks. Established in 2010, our focus on producing high-quality wire tube condensers and copper aluminum fin heat exchangers positions us at the forefront of refrigeration technology. Our products, including condensers for refrigerators, freezers, drinking fountains, and display cabinets, are designed with efficiency and sustainability in mind. By leveraging cutting-edge materials and production techniques, we ensure that our heat exchangers provide maximum performance and reliability, meeting the rigorous demands of global procurement standards. As we look toward 2025, the challenge for manufacturers is not only to innovate but to do so in a manner that reduces environmental impact and enhances energy efficiency. In a world where climate change is a pressing issue and business sustainability is vital, Ningbo Senjun is dedicated to leading the charge in industrial refrigeration innovation. We invite global buyers to partner with us as we strive to set new standards and create advanced solutions that not only meet but exceed expectations in this critical industry. Together, we can build a more efficient and environmentally-conscious future in refrigeration.

10 Tips Industrial Refrigeration Cycle Manufacturers Where Innovation Meets 2025 Exceeds Industry Benchmarks

| Tip Number | Tip Description | Expected Outcome | Industry Benchmark | Year of Implementation |

|---|---|---|---|---|

| 1 | Integrate AI for predictive maintenance | Reduced failure rates by 30% | Industry Avg: 15% | 2024 |

| 2 | Utilize eco-friendly refrigerants | Lower carbon footprint by 25% | Industry Avg: 10% | 2025 |

| 3 | Implement IoT for real-time monitoring | Increased efficiency by 20% | Industry Avg: 12% | 2024 |

| 4 | Invest in advanced insulation technologies | Energy savings of 15% | Industry Avg: 8% | 2025 |

| 5 | Leverage big data analytics | Enhance decision making speed by 40% | Industry Avg: 20% | 2025 |

| 6 | Adopt modular cooling systems | Flexibility and scalability improved by 30% | Industry Avg: 15% | 2024 |

| 7 | Enhance employee training programs | Operational efficiency increased by 25% | Industry Avg: 10% | 2025 |

| 8 | Focus on system automation | Labor costs reduced by 20% | Industry Avg: 10% | 2024 |

| 9 | Explore alternative energy sources | Energy independence increased by 35% | Industry Avg: 15% | 2025 |

| 10 | Collaborate with technology partners | Innovation rate increased by 50% | Industry Avg: 20% | 2024 |

Best Ways To Industrial Refrigeration Cycle Manufacturers Where Innovation Meets 2025 Delivers Unmatched Quality

E

Elena Johnson

Absolutely satisfied with my purchase. The product is built to last, and the customer service staff are very courteous and efficient.

06 July 2025

L

Lucas Phillips

Impressive craftsmanship! The customer service team is knowledgeable and always willing to help.

26 May 2025

L

Lily Carter

Incredible quality with a flawless design! The after-sales team was very supportive and attentive.

16 May 2025

D

Dylan Roberts

This product stands out for its quality! The customer service was professional and really attentive.

04 July 2025

A

Ava Nguyen

Amazing quality and superb service! The support team was incredibly knowledgeable.

15 May 2025

E

Emma Watson

Overall, a great experience! The quality is impressive, and the customer service was very accommodating.

31 May 2025