Top Industrial Exhaust Valve Manufacturers in China - Quality Factory Options

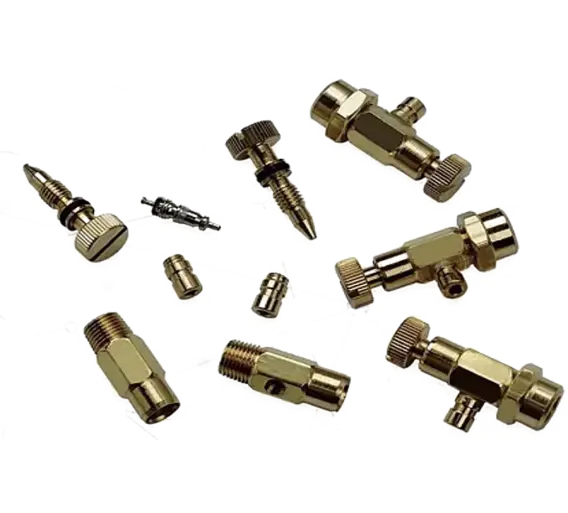

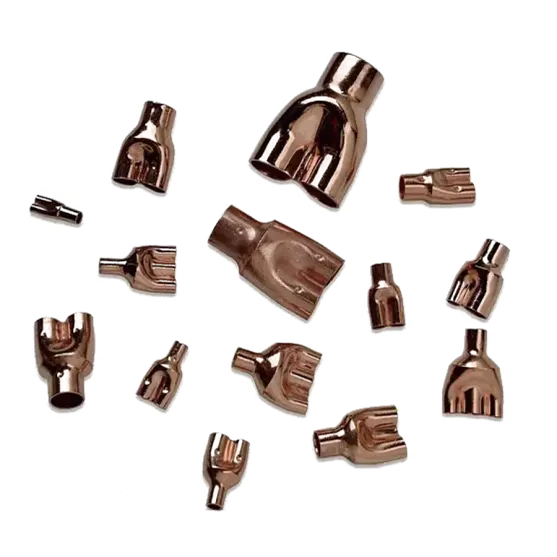

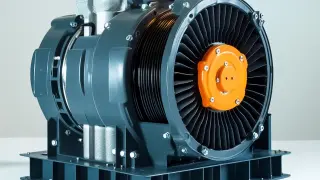

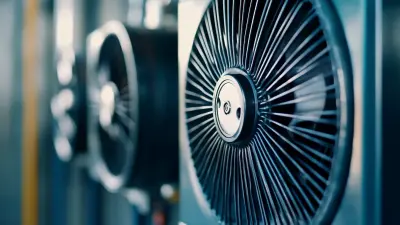

Ningbo Senjun New Materials Co., Ltd. specializes in high-quality industrial exhaust valves designed to enhance performance and efficiency in various applications. Engineered with advanced materials and cutting-edge technology, these valves ensure optimal control of exhaust flow, reducing emissions and improving overall system reliability, Our industrial exhaust valves boast exceptional durability, capable of withstanding extreme temperatures and corrosive environments, making them ideal for industries such as manufacturing, automotive, and power generation. The precision engineering allows for seamless integration into existing systems, while their low maintenance design ensures longevity and cost-effectiveness, In addition, our commitment to quality guarantees that every valve meets stringent international standards, providing customers with peace of mind. Choose our industrial exhaust valves for superior performance and innovation that drives your operations forward. Trust in Ningbo Senjun New Materials Co., Ltd. to deliver solutions that meet your specific needs in an ever-evolving industrial landscape

Advantages Explained Industrial Exhaust Valve Industry Giant Products

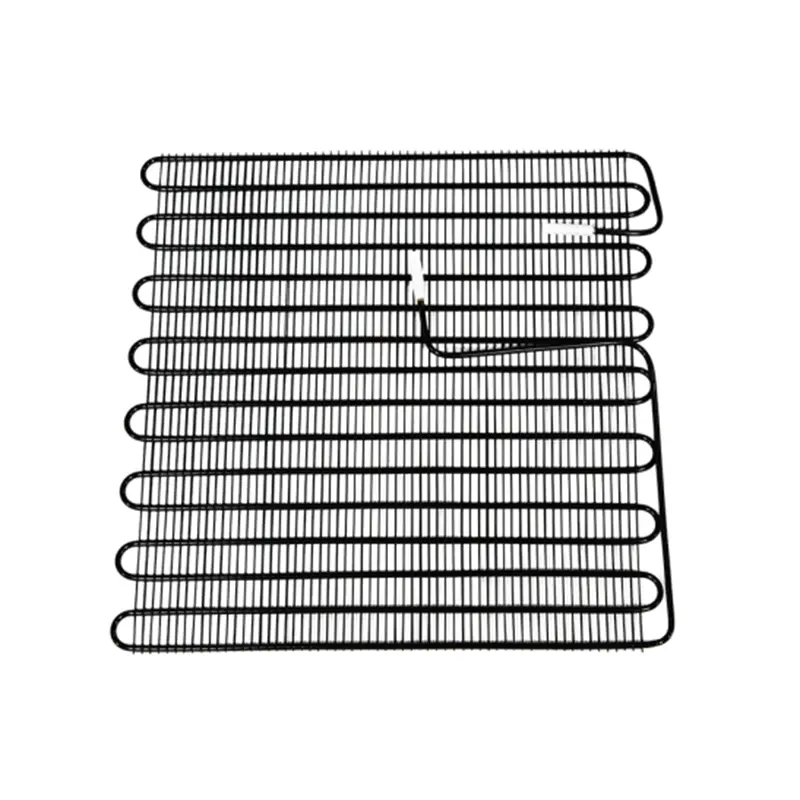

Ningbo Senjun New Materials Co., Ltd., established in 2010, has emerged as a leader in the industrial exhaust valve sector, specializing in innovative wire tube condensers and copper-aluminum fin heat exchangers. Our products are crucial components in various cooling applications, including refrigerators, freezers, drinking fountains, and display cabinets. What sets us apart in the competitive market is our unwavering commitment to research and development, which continuously enhances the efficiency and reliability of our offerings. One of the standout advantages of our industrial exhaust valves lies in their robust design and superior materials, ensuring longevity and performance even in demanding environments. By reducing energy consumption and minimizing maintenance costs, our products provide valuable savings for global buyers. Additionally, our advanced manufacturing techniques allow for customized solutions tailored to specific industry needs, making our valves not only versatile but also highly effective across multiple applications. When you choose Ningbo Senjun, you gain a partner dedicated to maintaining the highest standards of quality and performance. Our emphasis on sustainability and compliance with international standards further strengthens our position as an industry giant. By investing in eco-friendly technologies and processes, we help our clients meet their environmental goals while benefiting from superior product performance. With a proven track record and a focus on innovation, Ningbo Senjun New Materials Co., Ltd. is your go-to source for cutting-edge industrial exhaust valves that empower businesses worldwide.

Advantages Explained Industrial Exhaust Valve Industry Giant Products

| Product Type | Material | Size (mm) | Temperature Range (°C) | Pressure Rating (bar) | Application |

|---|---|---|---|---|---|

| Ball Valve | Stainless Steel | 50 | -20 to 100 | 16 | Chemical Processing |

| Gate Valve | Cast Iron | 80 | -10 to 80 | 10 | Water Supply |

| Globe Valve | Brass | 40 | -5 to 150 | 25 | Oil & Gas |

| Check Valve | Plastic | 25 | 0 to 60 | 5 | Waste Water Treatment |

| Butterfly Valve | Aluminum | 60 | -20 to 120 | 10 | HVAC Systems |

Top 10 Industrial Exhaust Valve Market Leader Leads the Global Market

A

Abigail Scott

Amazing product! The quality surpassed my expectations, and the support team was incredibly responsive.

25 May 2025

J

Jack Adams

This is a product of high quality. The after-sales service team was very knowledgeable and assisted me effectively.

26 June 2025

E

Elijah Ramirez

I’m very satisfied with my purchase! The product quality is excellent, and the customer service was very helpful.

17 June 2025

M

Mia Foster

Outstanding quality! The customer service representatives were extremely professional and attentive.

06 July 2025

L

Lucas Robinson

Impressive quality! Their customer service team is well-trained and very responsive.

09 May 2025

L

Lucas Turner

What a great product! Quality is outstanding, and the customer service was very professional.

06 June 2025