Industrial Copper Fin Heat Exchanger Suppliers in China - Top Factories

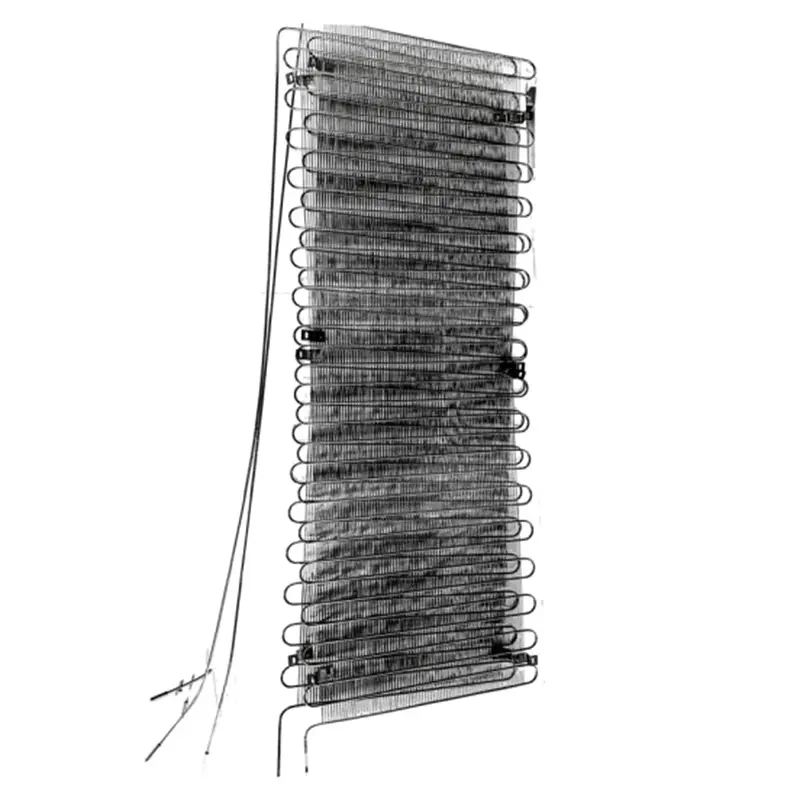

Enhancing thermal efficiency in various industrial applications, the Industrial Copper Fin Heat Exchanger by Ningbo Senjun New Materials Co., Ltd. stands out for its superior performance and durability. Designed to optimize heat transfer, this innovative product features copper fins that not only increase the surface area but also ensure efficient heat dissipation, Manufactured with high-quality materials, the heat exchanger is resistant to corrosion and wear, making it ideal for harsh operating conditions. Its lightweight design allows for easy installation and maintenance, reducing downtime in industrial processes, This heat exchanger is suitable for a variety of applications, including HVAC systems, refrigeration, and power generation, providing exceptional reliability and cost-effectiveness. With Ningbo Senjun’s commitment to quality and innovation, customers can trust that they are investing in a product that meets the highest industry standards. Choose the Industrial Copper Fin Heat Exchanger for unparalleled performance and efficiency in your operations

10 tips Industrial Copper Fin Heat Exchanger For the Current Year Supplier

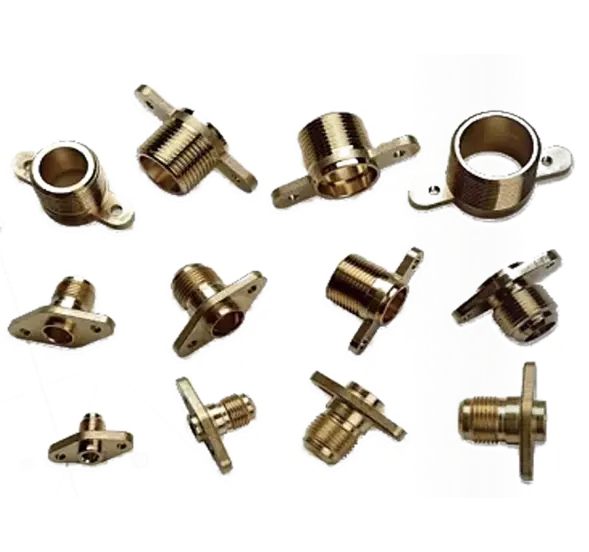

When it comes to sourcing industrial copper fin heat exchangers in the current market year, buyers demand efficiency, reliability, and innovation. At Ningbo Senjun New Materials Co., Ltd., founded in 2010, we pride ourselves on our extensive experience in the research and development of high-quality wire tube condensers and copper aluminum fin heat exchangers. Our products serve a wide range of industries, including refrigerators, freezers, drinking fountains, and display cabinets, making us a trusted partner for global procurement. To meet the modern demands of various sectors, it's crucial to consider several key tips when selecting a supplier. Firstly, prioritize companies that use advanced technology and materials in their manufacturing processes, as this impacts product durability and performance. Secondly, evaluate the supplier's ability to customize heat exchangers to fit specific operational requirements, ensuring an optimal solution for your application. Lastly, assess their commitment to sustainability and energy efficiency, as these factors are increasingly important to consumers and regulatory bodies worldwide. By choosing a reputable supplier like Ningbo Senjun, you can leverage our innovation-driven approach to obtain reliable and competitively priced industrial copper fin heat exchangers. Our dedication to quality and customer satisfaction ensures that your procurement choices align not just with business needs, but also with global sustainability goals.

10 Tips Industrial Copper Fin Heat Exchanger For the Current Year Supplier

| Tip Number | Tip Description | Key Benefits | Supplier Considerations |

|---|---|---|---|

| 1 | Evaluate material quality | Increased durability and efficiency | Choose suppliers with certified materials |

| 2 | Focus on energy efficiency | Lower operational costs | Look for suppliers with energy-efficient designs |

| 3 | Check for custom solutions | Better fit for unique applications | Ensure flexibility in manufacturing capabilities |

| 4 | Assess heat transfer efficiency | Improved performance and effectiveness | Request performance data from suppliers |

| 5 | Understand maintenance requirements | Longer lifespan and reliability | Evaluate ease of maintenance from suppliers |

| 6 | Review compliance standards | Meets regulatory requirements | Choose suppliers familiar with industry regulations |

| 7 | Consider price and value | Cost-effectiveness | Compare total cost of ownership |

| 8 | Investigate warranty and support | Peace of mind with purchases | Select suppliers offering robust support |

| 9 | Look for innovative technologies | Enhanced functionality | Partner with technology-focused suppliers |

| 10 | Request customer references | Confidence in supplier reliability | Verify past customer experiences |

Expert Tips For Industrial Copper Fin Heat Exchanger Global Reach Service

A

Andrew Kim

Impressive product quality! The after-sales service team is top-notch, always willing to assist with any concerns.

20 June 2025

B

Benjamin Graves

The quality is excellent! The customer service team was friendly and very communicative.

08 June 2025

A

Alexander Murphy

A truly wonderful experience! The quality of this product is exceptional, and the service was fast and friendly.

07 June 2025

M

Mia Foster

Outstanding quality! The customer service representatives were extremely professional and attentive.

06 July 2025

A

Ava Nguyen

Amazing quality and superb service! The support team was incredibly knowledgeable.

15 May 2025

H

Henry Martinez

Exceptional product quality! The customer service team went above and beyond to assist me.

27 June 2025