Fin Tube Type Manufacturers in China | Quality Factory Products

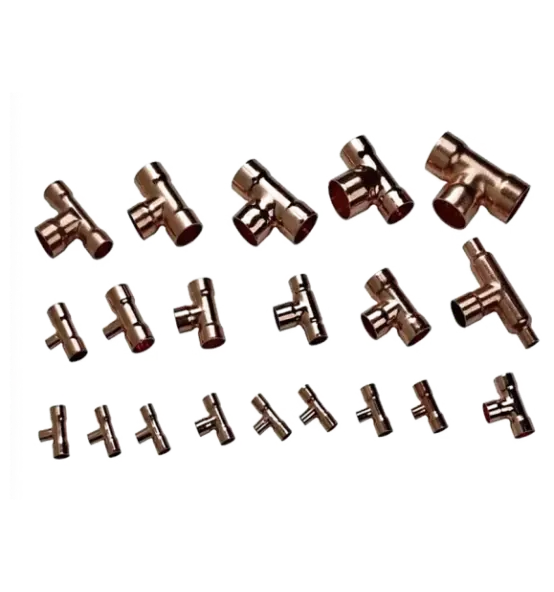

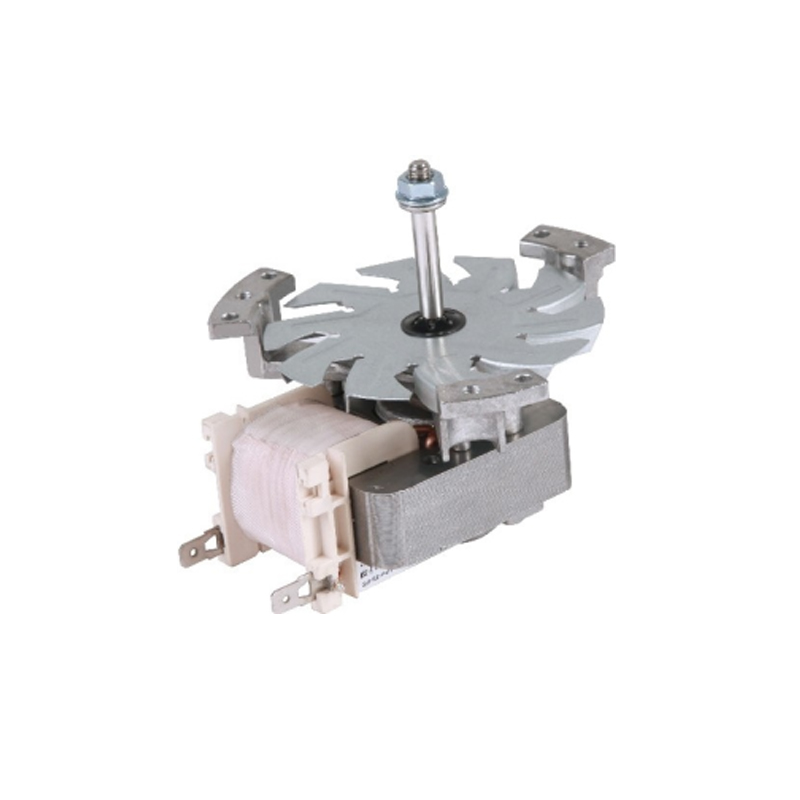

Discover the innovative Fin Tube Type solutions from Ningbo Senjun New Materials Co., Ltd., designed to enhance heat transfer efficiency across various applications. Our Finned Tubes are engineered with precision, providing superior performance in heating and cooling processes. The unique design increases surface area, allowing for optimal thermal exchange, making them ideal for industries such as HVAC, petrochemical, and power generation, Constructed using high-quality materials, our fin tubes ensure durability and reliability, even in demanding environments. The customizable options available cater to diverse operational needs, ensuring that you find the perfect fit for your systems, Ningbo Senjun New Materials Co., Ltd. prides itself on delivering exceptional products backed by comprehensive technical support and expertise. Our commitment to innovation and quality ensures that our customers benefit from efficient and effective solutions. Enhance your thermal management strategies today with our advanced Fin Tube Type products, and experience a new standard in performance and efficiency

The Secret to Fin Tube Type in 2025 Industry Leaders

As we approach 2025, the HVAC and refrigeration industries are witnessing transformative changes, particularly in the realm of fin tube technology. Ningbo Senjun New Materials Co., Ltd., established in 2010, has positioned itself at the forefront of these innovations, focusing on the development and production of advanced wire tube condensers and copper-aluminum fin heat exchangers. Our commitment to quality and efficiency has made us a trusted partner for businesses requiring high-performance solutions in refrigeration, freezers, drinking fountains, and display cabinets. The secret to becoming an industry leader in fin tube technology lies not only in understanding existing market demands but also in anticipating future trends. As global procurement professionals, it’s crucial to consider the environmental and energy efficiency standards driving product design. At Ningbo Senjun, we pride ourselves on integrating cutting-edge materials and manufacturing techniques that enhance the performance and durability of our heat exchangers. By investing in R&D, we are able to offer products that not only meet but exceed international standards, providing procurement partners with reliable options that align with their strategic goals. In 2025, the focus will be on sustainability and innovation, making it imperative for businesses to partner with manufacturers who are capable of delivering advanced solutions. As a leader in this field, Ningbo Senjun is dedicated to providing superior products that help our partners succeed in a competitive marketplace. Join us as we navigate the future of fin tube technology and explore opportunities for collaboration that will drive mutual growth and success.

The Secret to Fin Tube Type in 2025 Industry Leaders

| Fin Type | Material | Heat Transfer Efficiency (W/m²·K) | Market Share (%) | Average Cost ($/m) |

|---|---|---|---|---|

| Louvered Fin | Aluminum | 1500 | 25 | 40 |

| Plain Fin | Copper | 1200 | 30 | 50 |

| Wavy Fin | Stainless Steel | 1800 | 20 | 60 |

| Extruded Fin | Titanium | 2000 | 15 | 100 |

| Finned Tube | Carbon Steel | 1600 | 10 | 35 |

Top 3 Fin Tube Type Manufacturers You Can Rely On More Than a Supplier - A Partner

T

Thomas Brown

I can’t praise this product enough! The quality is remarkable, and the after-sales service has been incredibly supportive.

12 June 2025

E

Ethan Nelson

Quality product with a great finish! The support staff were professional and willing to help.

13 June 2025

E

Elijah Ramirez

I’m very satisfied with my purchase! The product quality is excellent, and the customer service was very helpful.

17 June 2025

L

Liam Bennett

I’ve had nothing but a positive experience! The product is of excellent quality and service team is very helpful.

15 June 2025

M

Mia Foster

Outstanding quality! The customer service representatives were extremely professional and attentive.

06 July 2025

E

Ella Hernandez

Absolutely wonderful quality! The support team was approachable and very helpful throughout.

08 June 2025