Wholesale Deaerating Air-Cooled Condensers from Top Manufacturers & Factories

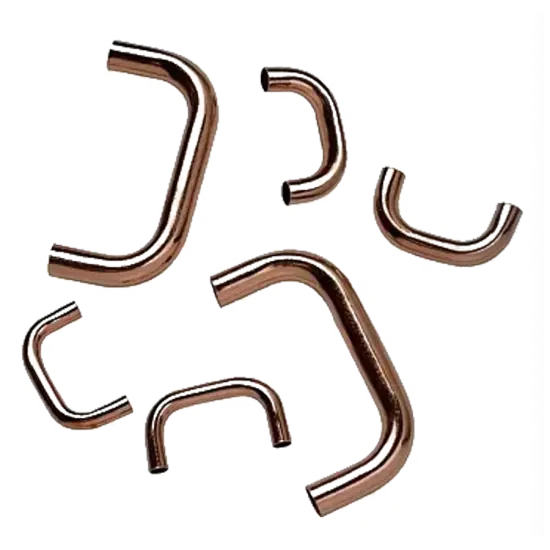

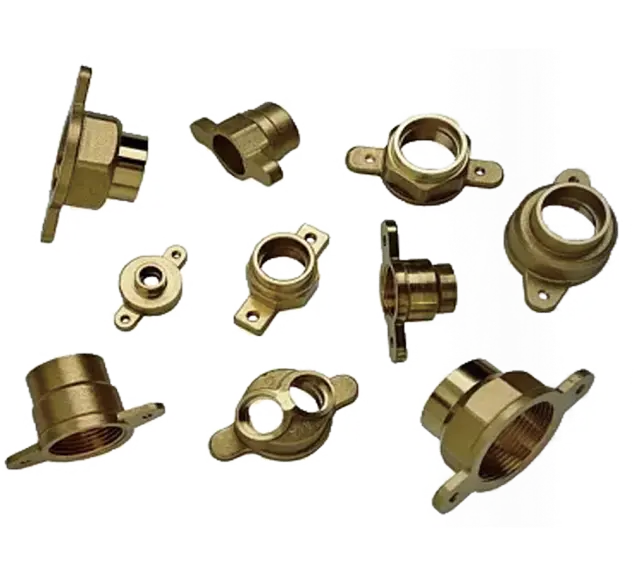

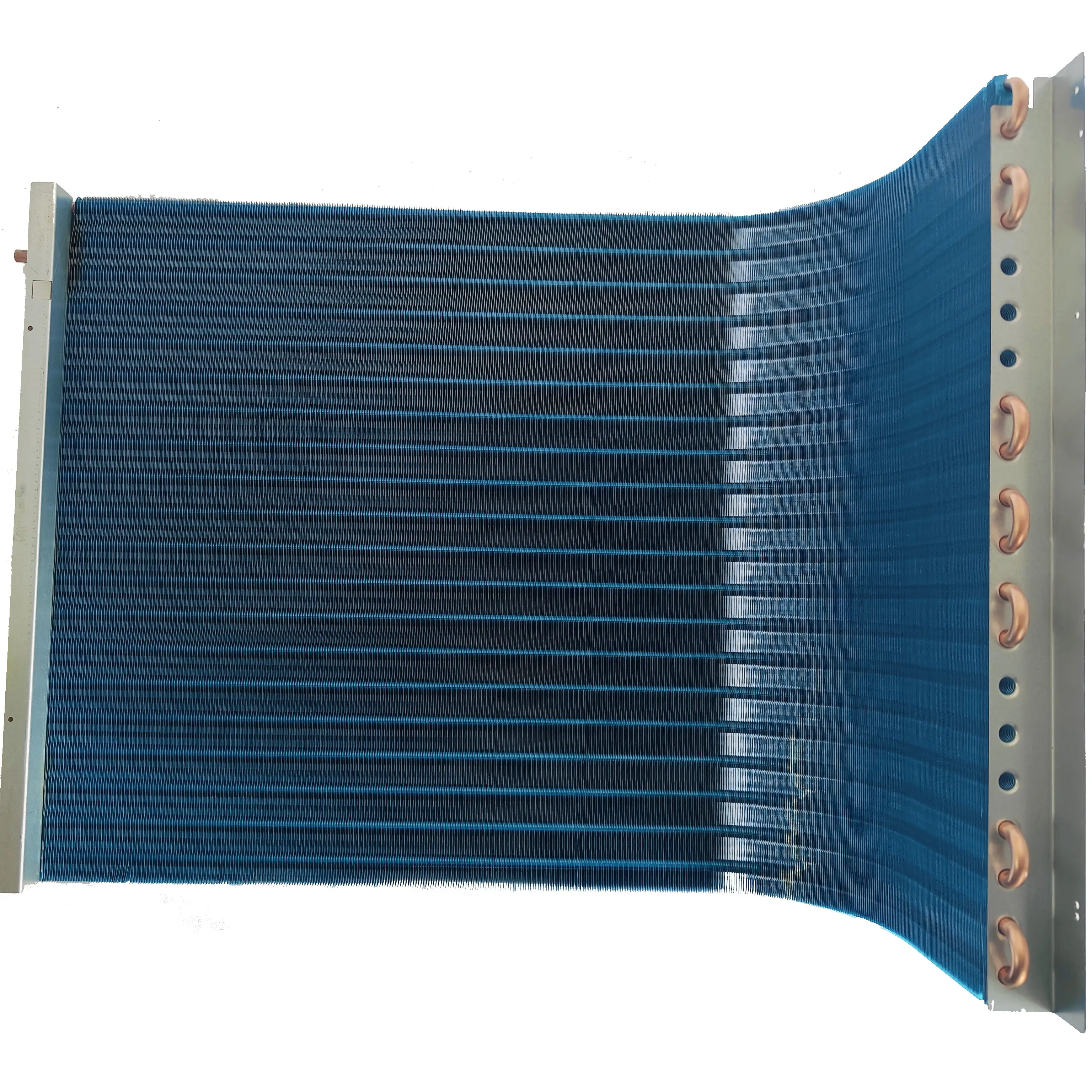

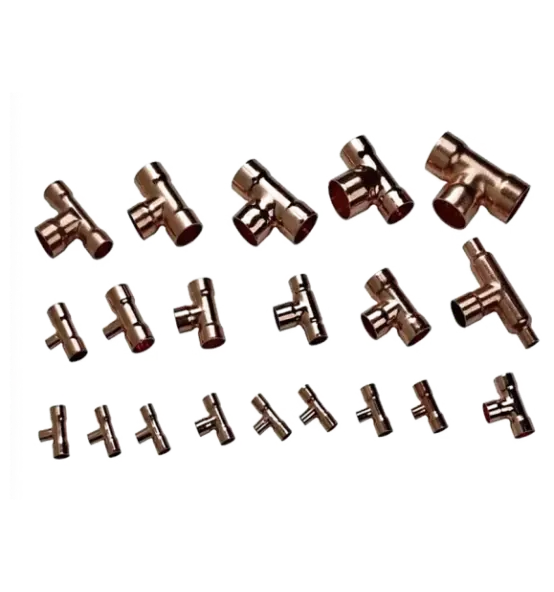

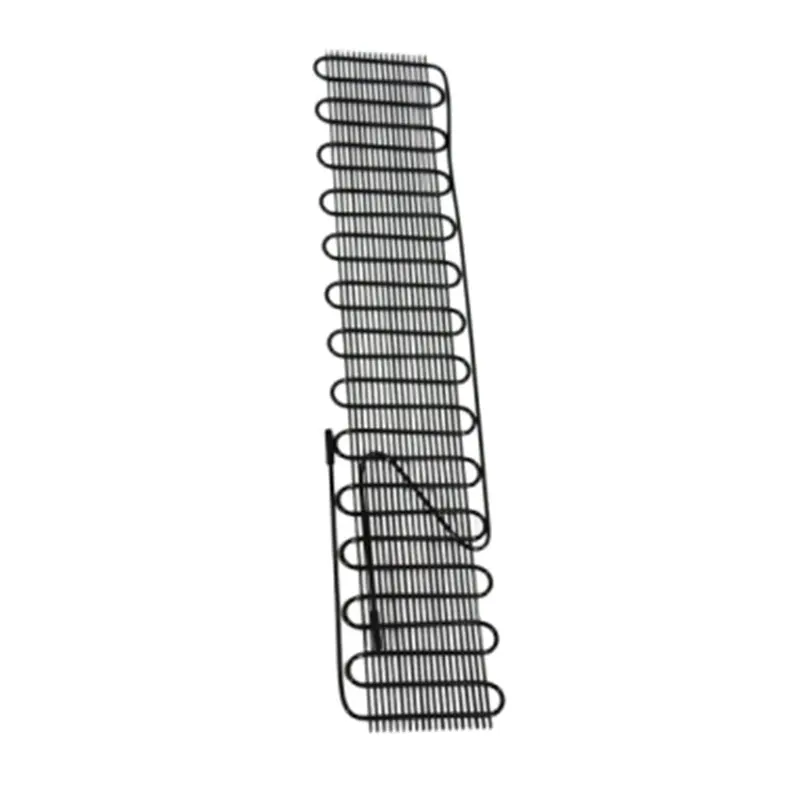

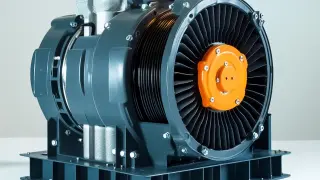

Enhance the efficiency of your cooling systems with the Deaerating Air-Cooled Condenser, a cutting-edge solution from Ningbo Senjun New Materials Co., Ltd. Designed for optimal performance, this advanced condenser effectively removes unwanted air and other non-condensable gases, significantly improving heat exchange efficiency, Constructed with high-quality materials, it ensures durability and reliability in a range of industrial applications. The unique design promotes seamless integration into existing systems, making it an ideal choice for HVAC, refrigeration, and power generation industries, With a focus on energy conservation and sustainability, the Deaerating Air-Cooled Condenser not only boosts performance but also reduces operational costs, contributing to a greener environment, Discover the perfect blend of innovation and efficiency while ensuring your system operates at peak performance. Trust in Ningbo Senjun New Materials Co., Ltd. for solutions that meet the demands of modern cooling technology. Ensure your systems run smoothly and efficiently with our state-of-the-art condensers

Best Practices For Deaerating Air-Cooled Condenser Factory Your End-to-End Solution

At Ningbo Senjun New Materials Co., Ltd., we understand that efficient operation is key for air-cooled condenser factories. Established in 2010, we specialize in the research, development, and production of high-quality wire tube condensers and copper aluminum fin heat exchangers, catering to various applications including refrigerators, freezers, drinking fountains, and display cabinets. In light of this expertise, we present best practices for deaerating air-cooled condensers to enhance performance and reliability, ensuring a superior end-to-end solution for our global partners. First and foremost, proper design and material selection are essential. Utilizing advanced manufacturing techniques and high-grade materials will reduce the risk of air entrapment. Incorporating venting features into your design allows for the swift release of air, which can cause inefficiencies. Additionally, implementing regular maintenance schedules will help in identifying and mitigating air accumulation issues, ensuring your systems operate at peak performance. Moreover, operators should adopt efficient deaeration techniques. Methods such as vacuum deaeration or thermal deaeration can significantly improve the efficiency of your condensers. By following these best practices, your air-cooled condenser factory can achieve optimal results, ultimately leading to increased customer satisfaction and a competitive edge in the market. Partner with Senjun and experience a tailored approach to meet your needs in the evolving HVAC industry.

Best Practices For Deaerating Air-Cooled Condenser Factory Your End-to-End Solution

| Practice | Description | Benefits | Frequency | Responsible Party |

|---|---|---|---|---|

| Regular Maintenance | Scheduled inspections and servicing of the condenser | Increases lifespan and efficiency of the condenser | Quarterly | Maintenance Team |

| Water Quality Testing | Testing for contaminants and oxygen levels in circulating water | Prevents corrosion and scaling, improving heat transfer | Monthly | Quality Control Team |

| Implementing Oxygen Scavengers | Use of chemical agents to remove dissolved oxygen | Reduces corrosion rates significantly | As needed | Operations Team |

| Ventilation Optimization | Adjusting airflow paths to enhance cooling | Improves system efficiency and reduces energy costs | Annual | Engineering Team |

| Training Sessions | Conducting workshops on best practices for personnel | Ensures proper operation and maintenance knowledge | Bi-annual | HR and Operations |

How To Decide Between Deaerating Air-Cooled Condenser Custom Solutions, Supplies the World’s Top Brands

S

Samantha Lee

Fantastic quality! This product exceeded my expectations. The support team was very knowledgeable and addressed all my queries promptly.

08 May 2025

T

Thomas Brown

I can’t praise this product enough! The quality is remarkable, and the after-sales service has been incredibly supportive.

12 June 2025

C

Carter Walker

Excellent product all around! The quality is phenomenal, and the support team was exceptionally helpful.

07 June 2025

L

Lucas Robinson

Impressive quality! Their customer service team is well-trained and very responsive.

09 May 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025

L

Liam Carter

Amazing quality! The support team was friendly and responsive to all my inquiries.

23 June 2025