Wholesale Corrosion-Resistant Needle Valve Manufacturer & Factory Direct

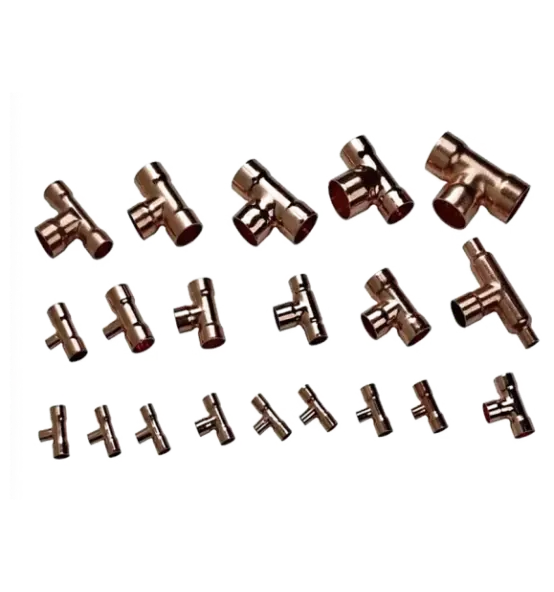

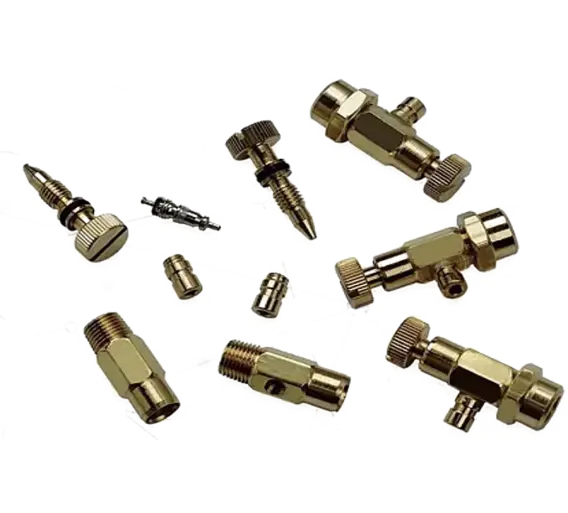

Ningbo Senjun New Materials Co., Ltd. proudly presents its corrosion-resistant Needle Valve, designed for precision flow control in challenging environments. Constructed from high-quality materials, these valves offer exceptional durability and reliability, making them ideal for applications involving harsh chemicals and corrosive substances, Engineered with meticulous attention to detail, our needle valves feature a sleek design that allows for seamless operation and minimal leakage. The corrosion-resistant properties ensure longevity, reducing maintenance costs and downtime. They are suitable for various industries, including chemical processing, oil and gas, and water treatment, where efficiency and safety are paramount, Customers can expect not only superior performance but also compliance with stringent industry standards. With a commitment to quality and innovation, Ningbo Senjun New Materials Co., Ltd. aims to provide solutions that meet the evolving needs of today's market. Elevate your operational efficiency with our state-of-the-art corrosion-resistant needle valves, setting a new benchmark in fluid control technology

Practical Methods To Corrosion-Resistant Needle Valve Pioneers in the Field Outperforms the Competition

In the competitive landscape of industrial components, corrosion-resistant needle valves represent a significant advancement for various applications, particularly in systems dealing with refrigeration, freezers, and other heat exchange technologies. At Ningbo Senjun New Materials Co., Ltd., we have positioned ourselves as pioneers in the development of these critical components. With over a decade of experience since our establishment in 2010, we pride ourselves on our dedication to research and innovation, enabling us to deliver products that not only meet but exceed industry standards. Our corrosion-resistant needle valves are engineered using cutting-edge materials and manufacturing techniques, ensuring superior performance and longevity even in the most demanding environments. This positions them as a reliable choice for global buyers looking to enhance the efficiency and reliability of their refrigeration and heat exchanger systems. By focusing on durability and resistance to harsh conditions, our valves outperform competitors, reducing maintenance costs and downtime for end-users. As the world increasingly prioritizes sustainability and efficiency, investing in high-quality components like our needle valves is more essential than ever. With a commitment to quality and customer satisfaction, Ningbo Senjun is ready to support your projects with innovative solutions that drive performance and value. Explore the capabilities of our needle valves today and experience the difference that expertise and dedication can make in your operations.

Practical Methods To Corrosion-Resistant Needle Valve Pioneers in the Field Outperforms the Competition

| Pioneer | Material Used | Corrosion Resistance Rating | Max Operating Pressure (psi) | Temperature Range (°C) |

|---|---|---|---|---|

| Pioneer A | Stainless Steel | 9/10 | 1500 | -40 to 200 |

| Pioneer B | Hastelloy | 10/10 | 2000 | -30 to 300 |

| Pioneer C | Monel | 8/10 | 1800 | -20 to 250 |

| Pioneer D | Titanium | 10/10 | 2200 | -50 to 400 |

10 tips Corrosion-Resistant Needle Valve Delivers Unmatched Quality Manufacturer

A

Ava Hall

Top-notch quality! The support team is very competent and helped resolve my issues swiftly.

21 May 2025

K

Kevin Walker

This product is fantastic! The quality is terrific, and the after-sales service was both prompt and professional.

16 June 2025

S

Sophia Young

Excellence in both product and service! The after-sales team provided the assistance I needed.

20 May 2025

A

Aiden Anderson

Superb craftsmanship! The customer service was impressive and went above and beyond.

10 June 2025

B

Brian James

The craftsmanship is remarkable! The after-sales service was quick and thorough.

28 May 2025

L

Liam Carter

Amazing quality! The support team was friendly and responsive to all my inquiries.

23 June 2025