China Copper Tube Aluminum Fin Coil Factory - Top Manufacturers & Suppliers

As a leading manufacturer in the industry, I’m excited to present our premium Copper Tube Aluminum Fin Coils, designed for optimal performance in various applications. We provide wholesale solutions tailored to meet the needs of B2B purchasers seeking reliable and efficient products. My team at Ningbo Senjun New Materials Co., Ltd. works diligently to ensure our coils are of the highest quality, ensuring durability and excellent heat exchange efficiency, With years of expertise, we understand the importance of reliable supply and competitive pricing. Our factory’s advanced manufacturing capabilities allow us to scale production to meet your specific requirements, while maintaining strict quality control. Choosing our Copper Tube Aluminum Fin Coils means partnering with a trusted manufacturer committed to your success. Let’s build a prosperous relationship that drives your business forward!

Why Copper Tube Aluminum Fin Coil Factory Is The Best Manufacturers You Can Rely On

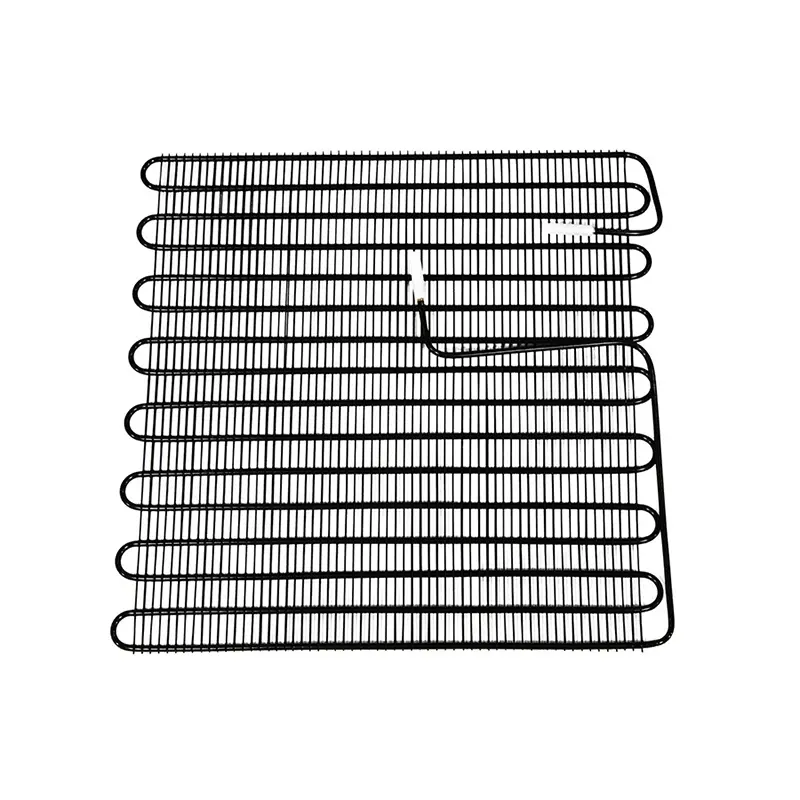

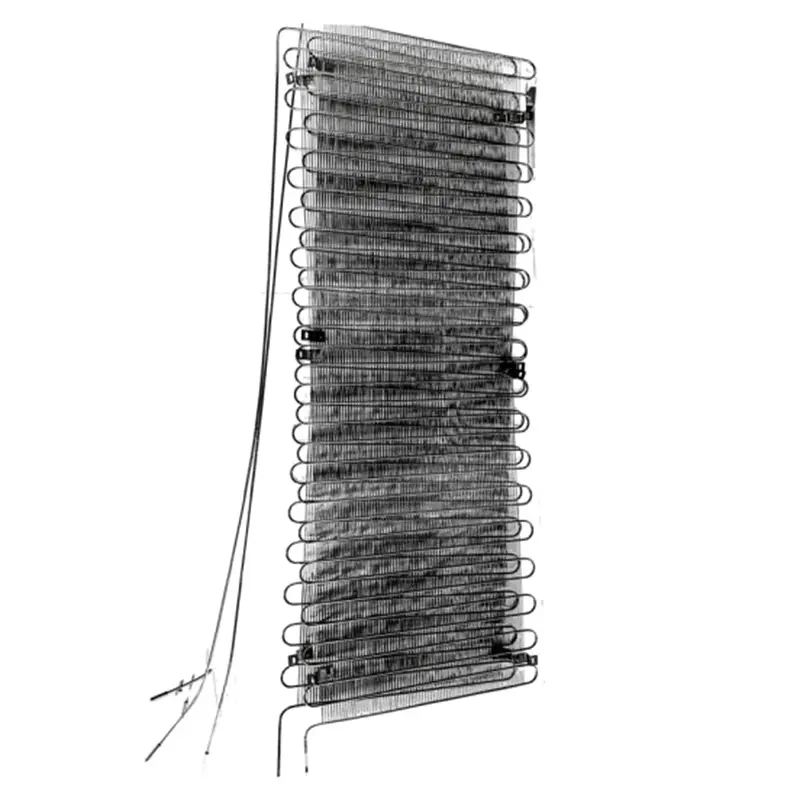

When it comes to sourcing high-quality heating and cooling solutions, copper tube aluminum fin coils are essential in various applications such as refrigerators, freezers, and display cabinets. Ningbo Senjun New Materials Co., Ltd., founded in 2010, has established itself as a leading manufacturer in this domain, dedicated to the research, development, and production of wire tube condensers and copper aluminum fin heat exchangers. Our commitment to innovation and quality sets us apart, making us the supplier that global buyers can trust. At Ningbo Senjun, we understand that reliability and efficiency are paramount for our clients. Our manufacturing process leverages advanced technology and rigorous quality control measures to ensure that every product meets international standards. This dedication not only maximizes the performance of your cooling systems but also extends their lifespan, providing you with exceptional value. Our experienced team continuously gathers feedback from clients around the world to enhance our offerings, ensuring that we stay ahead of market demands and trends. Choosing Ningbo Senjun means partnering with a company that prioritizes your needs. We are committed to delivering superior customer service, timely deliveries, and competitive pricing. Our extensive industry experience and understanding of global markets allow us to cater effectively to diverse requirements. By selecting our copper tube aluminum fin coils, you equip your business with reliable, efficient products backed by a partnership you can count on.

Why Copper Tube Aluminum Fin Coil Factory Is The Best Manufacturers You Can Rely On

| Feature | Description | Benefits |

|---|---|---|

| High-Quality Materials | Uses premium copper and aluminum. | Enhanced durability and efficiency. |

| Advanced Manufacturing Techniques | Incorporates modern machinery and technologies. | Improved production accuracy and speed. |

| Custom Solutions | Offers tailor-made products to meet specific needs. | Increased customer satisfaction and project success. |

| Energy Efficiency | Designed to optimize heat exchange. | Lower energy costs and reduced environmental impact. |

| Experienced Workforce | Skilled technicians with years of industry experience. | Quality craftsmanship and reliable products. |

| Comprehensive Support | Offers customer support throughout the purchase process. | Ensures a smooth and informed buying experience. |

Step-by-Step Guide To Copper Tube Aluminum Fin Coil Factory Now Trending Leads the Global Market

K

Kevin Walker

This product is fantastic! The quality is terrific, and the after-sales service was both prompt and professional.

16 June 2025

A

Avery Hughes

This product is simply outstanding! Great quality and superb service from the support team.

13 June 2025

E

Ethan Fisher

Impressive quality! The after-sales support team was attentive and provided great service.

15 June 2025

I

Isabella Williams

High-quality product with helpful and responsive customer service! A truly satisfying experience.

13 May 2025

A

Avery Baker

Superb product quality and excellent customer service! The support staff was very knowledgeable.

05 July 2025

L

Lucas Turner

What a great product! Quality is outstanding, and the customer service was very professional.

06 June 2025