Wholesale Copper Coil Fin Heat Exchanger - Manufacturer & Factory Supply

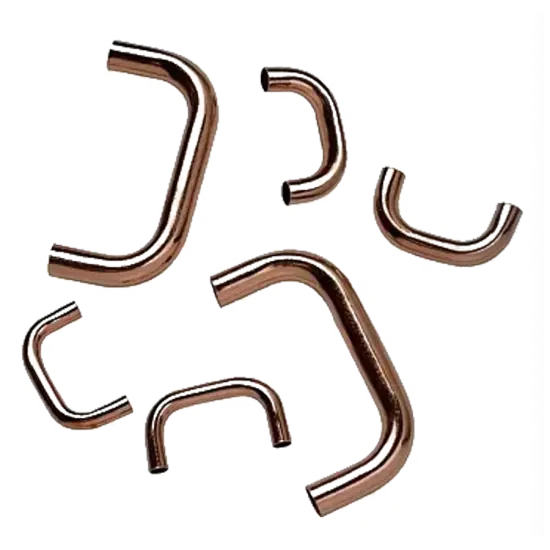

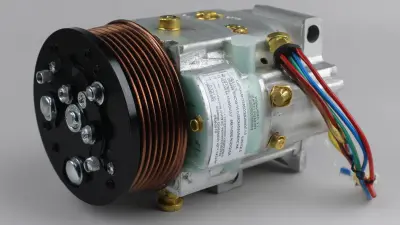

Ningbo Senjun New Materials Co., Ltd. presents an advanced Copper Coil Fin Heat Exchanger, engineered for optimal thermal performance and efficiency. This innovative solution combines the excellent thermal conductivity of copper with a unique fin design to enhance heat transfer capabilities, making it ideal for various applications, including HVAC systems, refrigeration, and industrial processes, Designed with precision, our copper coil fin exchangers ensure superior durability and longevity, even in challenging environments. The lightweight yet robust construction facilitates easy installation and maintenance, while the compact design maximizes space utilization without compromising performance, With a commitment to quality, each unit undergoes rigorous testing to meet industry standards, ensuring reliability and exceptional operational efficiency. Our heat exchangers not only contribute to energy savings but also support sustainable practices by reducing overall energy consumption. Trust Ningbo Senjun New Materials Co., Ltd. for cutting-edge solutions that elevate your thermal management systems to the next level

Smart Ways To Copper Coil Fin Heat Exchanger From Concept to Delivery Is The Best

At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on offering innovative solutions for cooling technology, particularly in the realm of copper coil fin heat exchangers. Since our inception in 2010, we have dedicated ourselves to the research, development, and production of high-quality wire tube condensers, as well as copper-aluminum fin heat exchangers tailored for various applications, including refrigerators, freezers, drinking fountains, and display cabinets. Our commitment to excellence ensures that we meet the diverse needs of global buyers seeking dependable and efficient cooling solutions. Our approach to designing and delivering copper coil fin heat exchangers is both strategic and customer-focused. From the initial concept stage to the final product delivery, we prioritize quality, performance, and sustainability. Each component of our heat exchangers is meticulously crafted, ensuring optimal heat transfer efficiency while minimizing energy consumption. By utilizing cutting-edge technology and adhering to international standards, we can guarantee that our products not only meet but exceed the expectations of our clients around the world. In an increasingly competitive market, we understand that procurement decisions hinge on both quality and reliability. By partnering with Ningbo Senjun, global buyers gain access to a comprehensive suite of products supported by our experienced team. We strive to provide not merely exceptional products but also unparalleled service, ensuring a seamless experience from concept to delivery. Whether you are looking to enhance your product line or improve operational efficiency, our copper coil fin heat exchangers are designed to deliver superior performance and value.

Smart Ways To Copper Coil Fin Heat Exchanger From Concept to Delivery Is The Best

| Dimension | Value | Description |

|---|---|---|

| Copper Coil Diameter | 12 mm | Standard diameter for heat exchange efficiency |

| Fin Thickness | 0.5 mm | Optimal for thermal performance |

| Heat Exchanger Area | 1.5 m² | Total surface area for heat transfer |

| Design Pressure | 1.5 MPa | Pressure rating for safety standards |

| Testing Temperature | 80 °C | Maximum operational temperature |

| Production Lead Time | 4 weeks | Time from order to delivery |

| Warranty Period | 2 years | Coverage for defects in materials and workmanship |

Excellence in Copper Coil Fin Heat Exchanger Industry Leaders Global Reach

D

David Martinez

I highly recommend this product. Not only is it of superior quality, but the after-sales support has been outstanding.

06 July 2025

J

Jessica Patel

The quality of the item is remarkable! Plus, the customer service was so professional and helpful throughout the entire process.

05 July 2025

B

Brian Chen

This product is fantastic! The quality is really high, and their customer service was professional and quite helpful.

23 June 2025

E

Ethan Nelson

Quality product with a great finish! The support staff were professional and willing to help.

13 June 2025

B

Benjamin Graves

The quality is excellent! The customer service team was friendly and very communicative.

08 June 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025