China Manufacturers of Condensing Heat Exchanger for Steam Materials

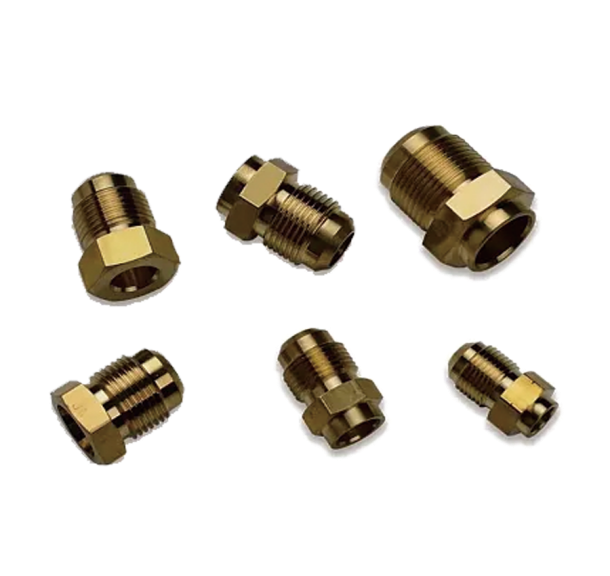

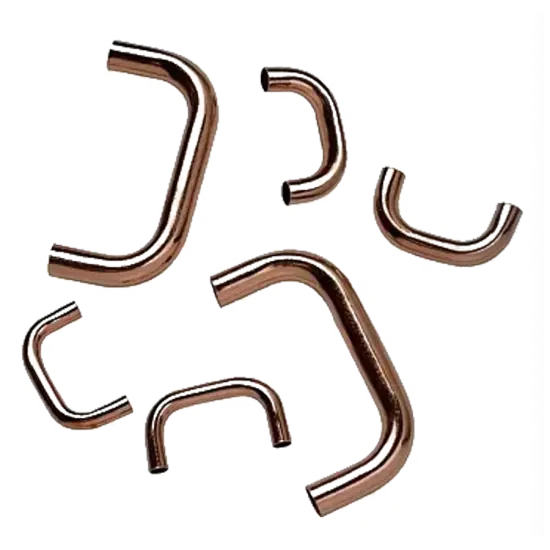

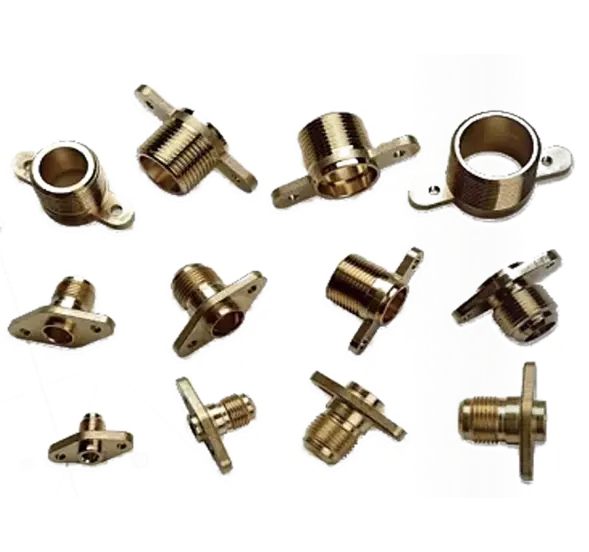

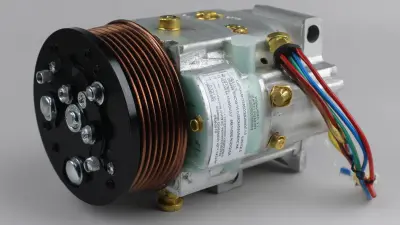

Experience enhanced efficiency with our Condensing Heat Exchanger for Steam, crafted with precision by Ningbo Senjun New Materials Co., Ltd. This innovative heat exchanger is designed to maximize energy recovery while minimizing operational costs. Built from advanced materials, it offers exceptional thermal conductivity and corrosion resistance, ensuring longevity and reliable performance even in demanding environments, Our design optimizes steam condensation, transforming thermal energy into usable heat, making it ideal for diverse industrial applications. Whether it’s for power generation, chemical processing, or HVAC systems, this heat exchanger facilitates increased efficiency and reduced energy consumption, With a focus on quality and sustainability, Ningbo Senjun New Materials Co., Ltd. is committed to providing products that meet the highest standards. Trust in our expertise and state-of-the-art technology to enhance your systems with effective heat recovery solutions. Embrace a more energy-efficient future with our Condensing Heat Exchanger for Steam

Smart Ways To Condensing Heat Exchanger For Steam Material Now Trending Factory

As global industries seek to enhance energy efficiency and reduce operational costs, the demand for innovative heat exchange solutions continues to rise. At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on being at the forefront of this trend with our cutting-edge wire tube condensers and copper-aluminum fin heat exchangers. Since our establishment in 2010, we have dedicated ourselves to advancing the technology behind these thermal management systems, catering to a variety of applications including refrigerators, freezers, drinking fountains, and display cabinets. Our latest developments in condensing heat exchangers focus on optimizing steam material performance while ensuring compact designs that fit seamlessly into modern manufacturing environments. By leveraging advanced materials and engineering techniques, we can produce heat exchangers that not only maximize energy transfer efficiency but also minimize space requirements. This dual benefit is crucial for factories looking to streamline operations and enhance productivity without sacrificing quality. For global buyers, investing in our innovative solutions means gaining access to reliable, high-performance products that are tailored to meet the unique demands of their industrial processes. As we continue to explore smart ways to refine our heat exchanger designs, we invite you to partner with us and leverage our expertise to drive your business forward. Together, we can create value and foster sustainable growth in today’s competitive marketplace.

Smart Ways To Condensing Heat Exchanger For Steam Material Now Trending Factory

| Method | Efficiency (%) | Material Used | Cost ($/unit) | Market Trend |

|---|---|---|---|---|

| Thermal Fins Addition | 85 | Copper | 150 | Increasing |

| Multi-Stream Flow Design | 90 | Stainless Steel | 200 | Stable |

| Heat Recovery Systems | 92 | Aluminum | 180 | Growing |

| Phase Change Materials | 88 | Polymer Composites | 220 | Emerging |

| Advanced Control Systems | 95 | Titanium | 300 | High Demand |

10 tips Condensing Heat Exchanger For Steam Material For the Current Year Delivers Unmatched Quality

D

David Martinez

I highly recommend this product. Not only is it of superior quality, but the after-sales support has been outstanding.

06 July 2025

R

Rachel Green

Quality and service are both exceptional! I received prompt assistance from the support team, which made my experience even better.

28 June 2025

S

Sophia Martinez

I’m thrilled with this product! The quality is outstanding, and the customer service really goes above and beyond.

27 June 2025

J

James Adams

A product that truly stands out! Quality is superb and the customer service team is highly professional.

04 July 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025

C

Charlotte Mitchell

This product is wonderful! The quality is high, and the customer service team excelled in their support.

17 May 2025