Wholesale Closed Air Refrigeration System Factory – Manufacturer & Supplier

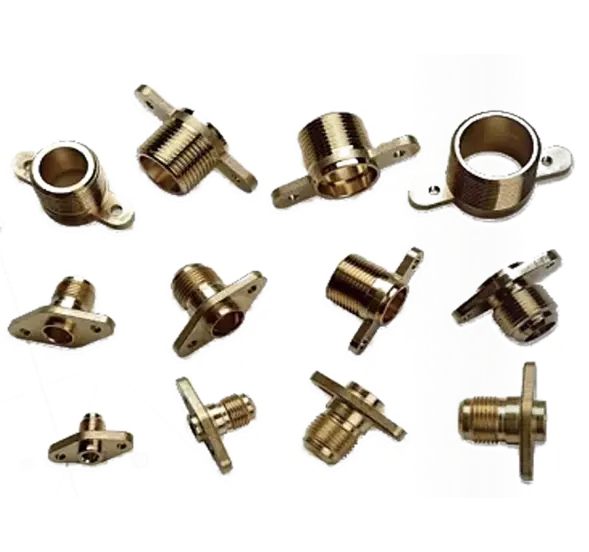

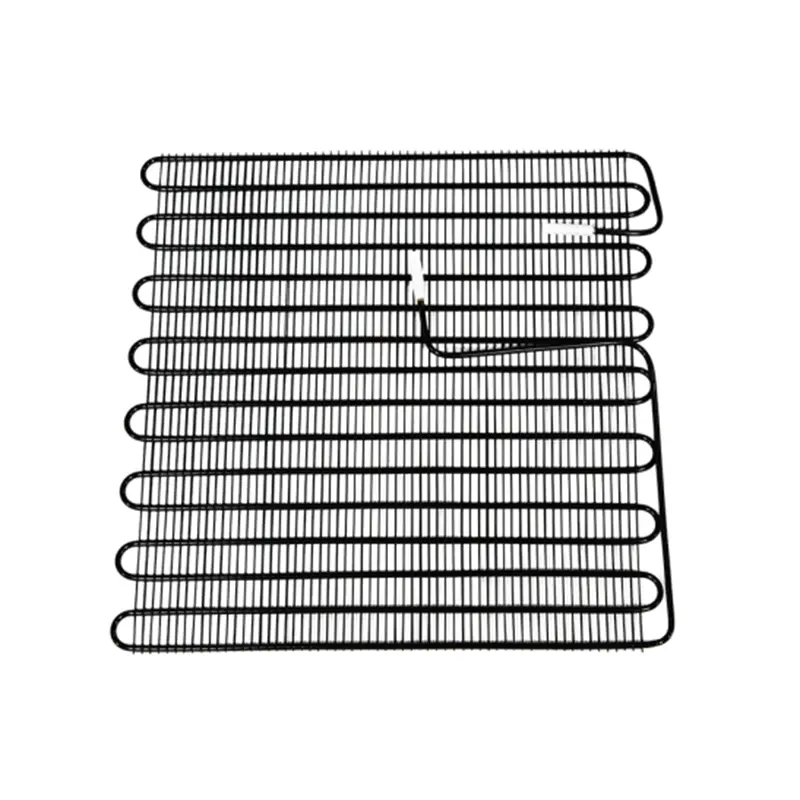

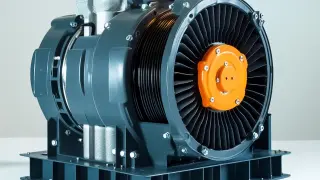

At Ningbo Senjun New Materials Co., Ltd., we specialize in manufacturing high-quality Closed Air refrigeration Systems tailored for various industrial applications. As a leading wholesale supplier, our systems are designed to enhance energy efficiency while maintaining optimal cooling performance. We understand that precision and reliability matter to our B2B customers, which is why we focus on innovative designs and robust materials

Best Practices For Closed Air Refrigeration System Factory Pioneers in the Field Manufacturer

In the rapidly evolving landscape of refrigeration technology, closed air refrigeration systems have emerged as a vital solution for various industries. As pioneers in this field, Ningbo Senjun New Materials Co., Ltd. leverages over a decade of expertise to offer cutting-edge wire tube condensers and copper aluminum fin heat exchangers that cater to a diverse range of applications, including refrigerators, freezers, drinking fountains, and display cabinets. Our commitment to innovation and quality not only enhances efficiency but also supports sustainability in refrigeration systems. To optimize the performance of closed air refrigeration systems, manufacturers should adhere to best practices that ensure reliability and energy efficiency. Firstly, selecting high-quality materials like those used in our condensers guarantees maximum heat transfer and durability. Additionally, regular maintenance and the adoption of smart technologies will allow operators to monitor system performance in real-time, leading to timely interventions and reduced downtime. With our products, clients are equipped with solutions that embody reliability and cutting-edge engineering, offering peace of mind in their refrigeration needs. As the global market for efficient refrigeration solutions expands, partnering with a trusted manufacturer like Ningbo Senjun can streamline your procurement process. Our state-of-the-art manufacturing processes and commitment to innovation ensure that we meet not only current industry standards but also anticipate future needs. Collaborating with us not only enhances your product offerings but also positions your business at the forefront of the refrigeration industry.

Best Practices For Closed Air Refrigeration System Factory Pioneers in the Field Manufacturer

| Best Practice | Description | Benefits | Implementation Steps |

|---|---|---|---|

| Regular System Maintenance | Conduct routine checks and maintenance of the refrigeration system. | Increases system efficiency and lifespan. | Schedule monthly inspections and servicing. |

| Energy-efficient Components | Utilize high-efficiency compressors and evaporators. | Reduces energy consumption and costs. | Invest in modern, energy-rated equipment. |

| Proper Insulation | Ensure all refrigeration piping is well-insulated. | Minimizes heat gain and improves efficiency. | Use high-quality insulation materials. |

| Leak Detection | Implement continuous monitoring for refrigerant leaks. | Prevents loss of refrigerant and operational downtimes. | Install leak detection systems and conduct regular checks. |

| Professional Training | Train staff on best practices for system operation and maintenance. | Enhances safety and efficiency in operations. | Conduct regular training sessions and workshops. |

Curated Selection of Closed Air Refrigeration System Factory Ahead of the Curve Service Backed by Expertise

R

Rachel Green

Quality and service are both exceptional! I received prompt assistance from the support team, which made my experience even better.

28 June 2025

S

Sophia Martinez

I’m thrilled with this product! The quality is outstanding, and the customer service really goes above and beyond.

27 June 2025

D

Daniel Clark

High-quality product with an impressive finish. The support team was very knowledgeable and addressed my concerns promptly.

16 June 2025

D

Dylan Ross

This product is fantastic! The support team provided exceptional guidance and assistance.

02 June 2025

R

Ryan Clark

Great product! The quality is unmatched, and the after-sales service was incredibly supportive.

18 May 2025

A

Alexander Johnson

I’m thoroughly impressed with this product! The quality is exceptional, and the support team was top-notch.

06 June 2025