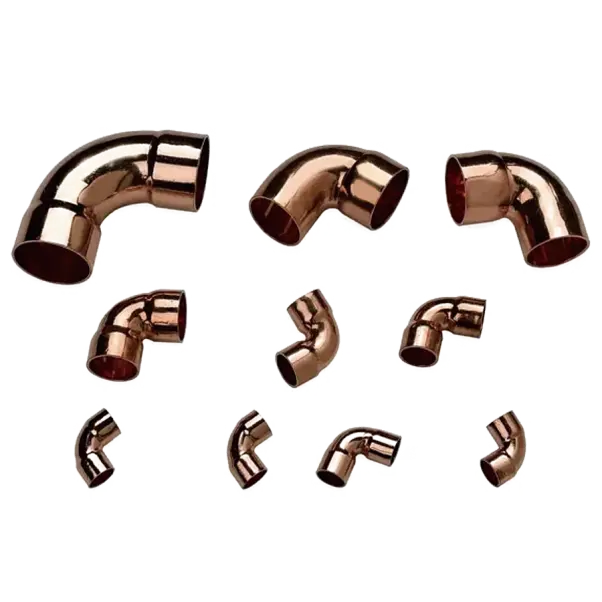

Brass Coupling for Refrigeration Systems - Top Suppliers in China

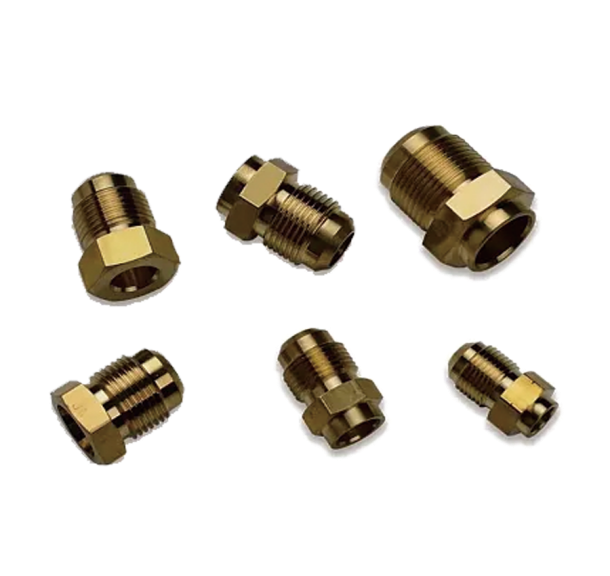

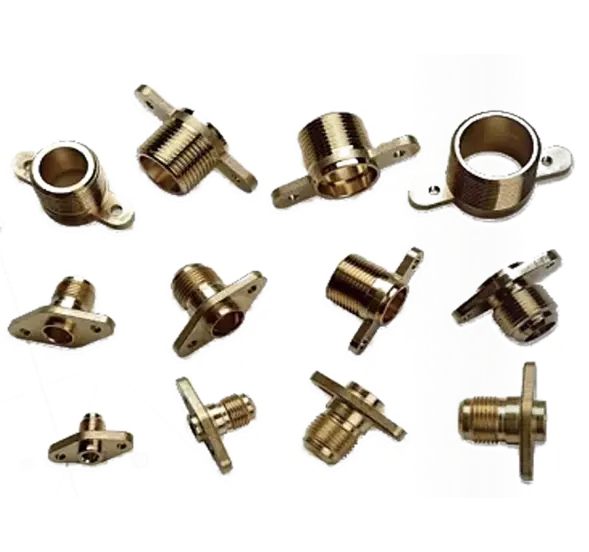

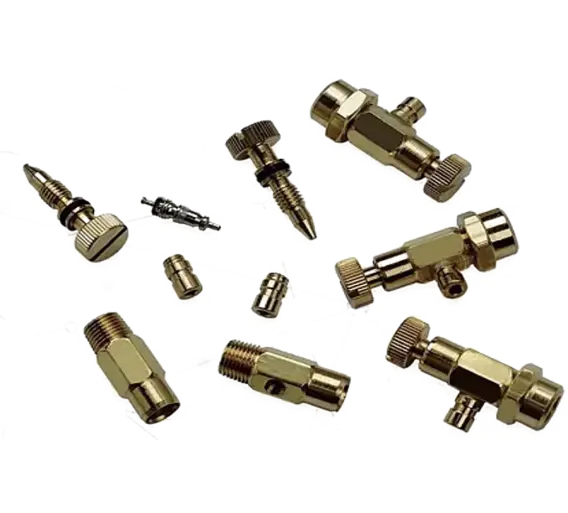

Experience unrivaled quality with our Brass Couplings designed specifically for refrigeration systems. Crafted by Ningbo Senjun New Materials Co., Ltd., these couplings offer exceptional durability and reliability, ensuring optimal performance in demanding environments. The superior corrosion resistance of brass material makes our couplings ideal for various refrigerants, safeguarding your systems from leaks and minimizing maintenance costs, Our Brass Couplings feature precision-engineered designs that allow for easy installation and a secure fit, enhancing the overall efficiency of your refrigeration setup. With a commitment to excellence, we prioritize both functionality and sustainability, offering products that meet rigorous industry standards, Whether you’re in the HVAC industry or involved in manufacturing refrigeration equipment, our Brass Couplings provide the perfect solution for enhancing system integrity and longevity. Trust in Ningbo Senjun New Materials Co., Ltd. for high-quality components that meet your refrigeration needs with unmatched performance and reliability

Best Practices For Brass Coupling for Refrigeration Systems Your Trusted OEM Partner For the Current Year

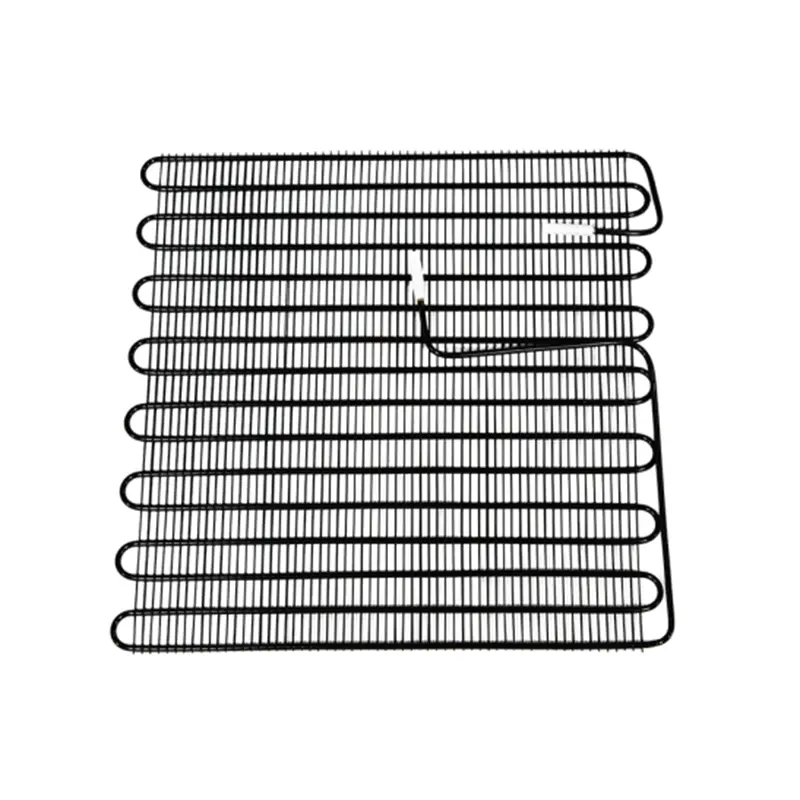

When it comes to optimizing refrigeration systems, the choice of components is crucial. Brass couplings, for instance, play a significant role in ensuring the efficiency and reliability of these systems. At Ningbo Senjun New Materials Co., Ltd., we understand that selecting the right coupling can enhance performance, reduce maintenance costs, and ensure longevity. As a trusted OEM partner, we focus on delivering products that align with industry best practices, providing our global customers with high-quality solutions. One best practice to consider when using brass couplings in refrigeration systems is to ensure proper sizing and compatibility with your existing components. Properly sized couplings help maintain system pressure and efficiency while preventing leaks. Additionally, it is vital to choose brass that meets international standards to withstand varying temperatures and pressures typical in refrigeration applications. Our experience in developing wire tube condensers and copper Aluminum Fin heat exchangers since 2010 equips us with the expertise to guide purchasing decisions, ensuring the longevity and reliability of your refrigeration system. Furthermore, regular maintenance and monitoring of brass couplings can prevent failure and extend system life. Our commitment to quality and innovation means we provide not just products, but comprehensive solutions that empower our clients worldwide. Collaborating with Ningbo Senjun New Materials Co., Ltd. ensures that your refrigeration systems are equipped with the best materials necessary for optimal performance. Together, we can achieve operational excellence in your refrigeration applications this year and beyond.

| Best Practice | Description | Benefits | Frequency of Use |

|---|---|---|---|

| Regular Inspection | Check for signs of wear and corrosion. | Prevention of leaks and enhanced system longevity. | Monthly |

| Proper Torque Settings | Follow manufacturer’s torque specifications. | Ensures secure connections and reduces breakage risk. | With each installation |

| Using Suitable Sealants | Select sealants compatible with refrigerants. | Enhances sealing performance and prevents leaks. | As needed |

| Training Personnel | Ensure technicians are knowledgeable about installation and maintenance. | Reduces errors and promotes safety. | Annually |

| Maintain Proper Refrigerant Levels | Ensure refrigerant levels are within manufacturer specifications. | Optimizes system performance and prevents compressor damage. | Quarterly |

Excellence in Brass Coupling for Refrigeration Systems Factory Custom Solutions,

E

Elena Johnson

Absolutely satisfied with my purchase. The product is built to last, and the customer service staff are very courteous and efficient.

06 July 2025

B

Brian Chen

This product is fantastic! The quality is really high, and their customer service was professional and quite helpful.

23 June 2025

J

James Wilson

Exceptional quality! The after-sales service representatives were responsive and educated, making me feel valued.

18 June 2025

G

Grace Hall

Truly delighted with my purchase. The quality is outstanding, and the after-sales service exceeded my expectations.

30 May 2025

Z

Zoe Rivera

I love the quality! The support team was really friendly and addressed all my questions effectively.

05 June 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025