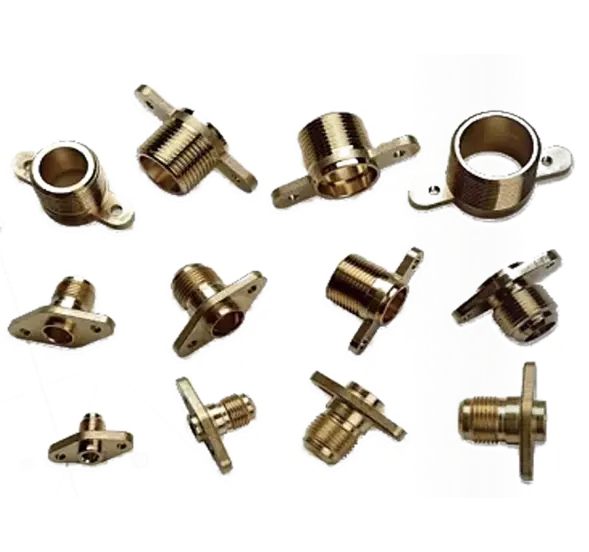

Wholesale Brass Connector with Ear Joint Design - Manufacturer & Factories

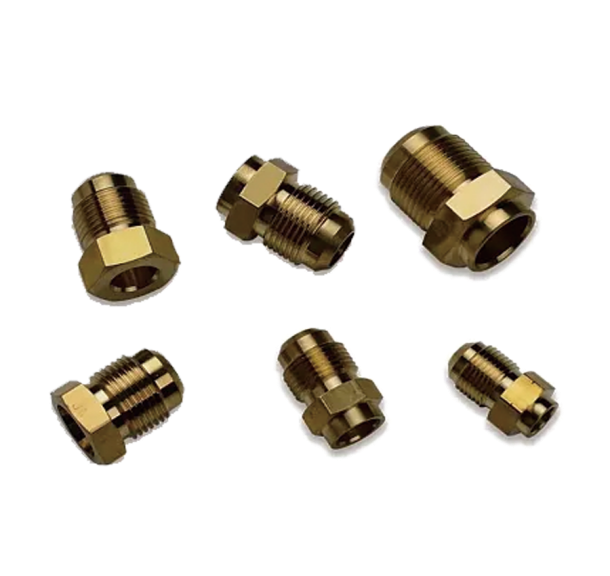

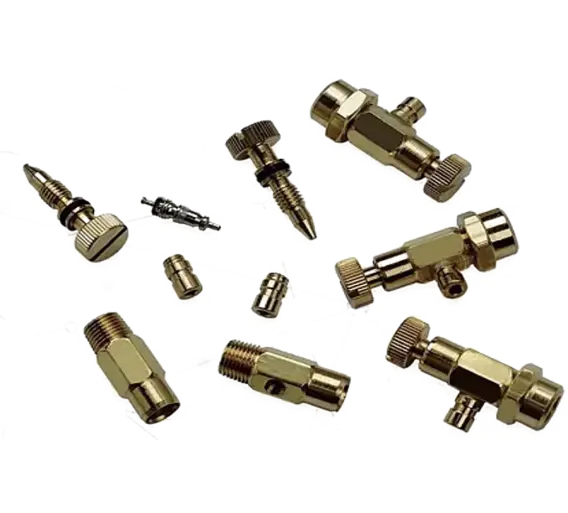

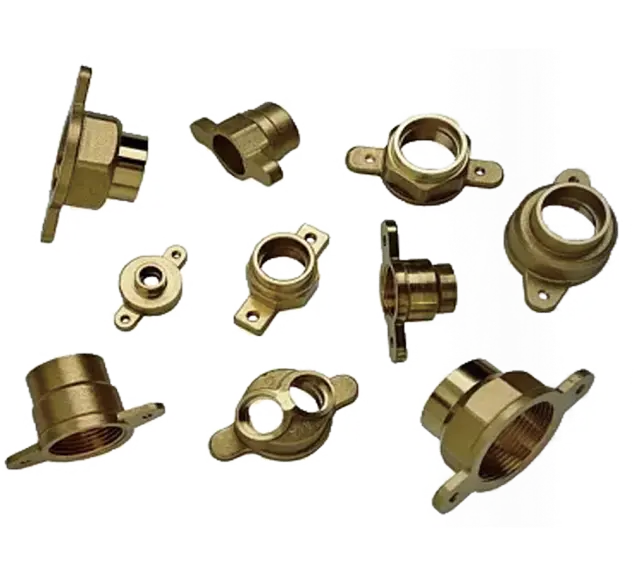

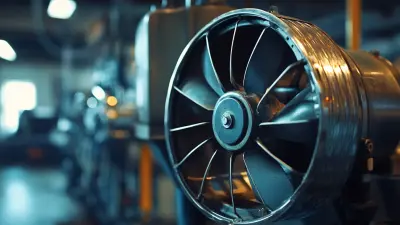

Crafted for exceptional performance and durability, the Brass Connector with Ear Joint Design is a standout solution from Ningbo Senjun New Materials Co., Ltd. This innovative connector is engineered to ensure a secure and reliable connection in various applications, making it ideal for plumbing, HVAC Systems, and industrial machinery, The ear joint design enhances stability and ease of installation while minimizing potential leaks and ensuring long-term functionality. Made from high-quality brass, this connector resists corrosion, providing a robust option even in challenging environments. Its compatibility with a wide range of pipe sizes and materials makes it versatile for different projects, Whether you're upgrading your infrastructure or tackling a DIY project, this brass connector promises efficiency and peace of mind. Trust in Ningbo Senjun New Materials Co., Ltd. for reliable products that elevate your performance standards. Experience the difference innovation and quality can make with our Brass Connector with Ear Joint Design

Key Methods For Brass Connector with Ear Joint Design Now Trending Industry Giant

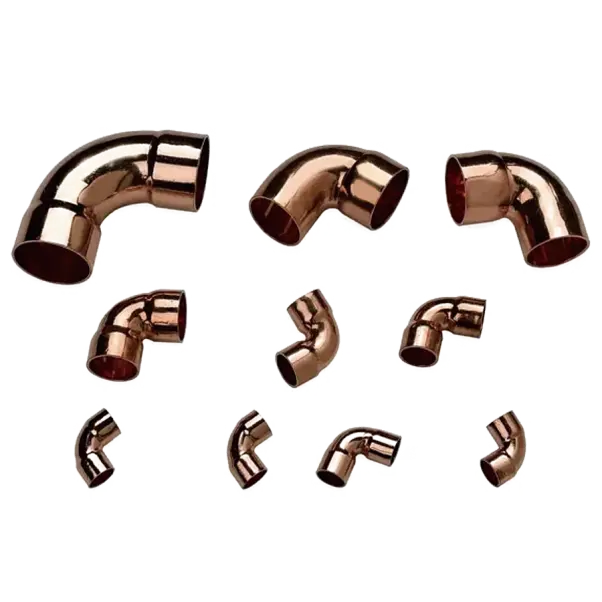

In today's competitive market, the demand for innovative and efficient components is ever-growing, particularly in industries reliant on cooling solutions. One such critical component gaining traction is the brass connector with ear joint design. This design not only enhances the mechanical strength of connections but also minimizes the risk of leaks, making it an essential choice for industries like refrigeration, food service, and display cabinets. Ningbo Senjun New Materials Co., Ltd., established in 2010, focuses on the research and development of cutting-edge solutions for wire tube condensers and copper-aluminum fin heat exchangers. With our extensive experience in producing high-quality components, we understand that durability and reliability are paramount for global buyers seeking long-lasting performance in their products. Our brass connectors, designed with the latest trends and technologies in mind, offer unparalleled efficiency and compatibility with a wide range of applications, ensuring that your refrigeration and cooling systems operate at their best. As the industry shifts towards more sustainable and efficient designs, incorporating advanced materials like our brass connectors with ear joint design can significantly enhance the overall performance of your systems. By choosing Ningbo Senjun as your partner, you are not only investing in superior quality but also in a commitment to innovation and customer satisfaction. Let's work together to meet the rising standards of this rapidly evolving sector.

Key Methods For Brass Connector with Ear Joint Design Now Trending Industry Giant

| Method | Description | Material Used | Industry Applications | Benefits |

|---|---|---|---|---|

| Cold Forging | A manufacturing process that shapes brass by deforming it at room temperature. | Brass Alloy | Electronics, Plumbing, Automotive | Higher strength, better surface finish, and reduced waste. |

| CNC Machining | Computer-controlled process for precise cutting and shaping of brass components. | High-Quality Brass | Aerospace, Medical Devices | High precision, complex geometry, and rapid prototyping. |

| Die Casting | Molten brass is forced into a mold cavity under high pressure. | Brass with Zinc | Consumer Electronics, Automotive | High production rates, uniform thickness, and fine details. |

| Soldering | Joining metal pieces by melting solder around the joint. | Various Solders | Electronics, Plumbing | Excellent electrical conductivity and strong joints. |

Step-by-Step Guide Brass Connector with Ear Joint Design Delivers Unmatched Quality Guarantees Peak Performance

T

Thomas Brown

I can’t praise this product enough! The quality is remarkable, and the after-sales service has been incredibly supportive.

12 June 2025

E

Ethan Nelson

Quality product with a great finish! The support staff were professional and willing to help.

13 June 2025

Z

Zoe Rivera

I love the quality! The support team was really friendly and addressed all my questions effectively.

05 June 2025

A

Alexander Murphy

A truly wonderful experience! The quality of this product is exceptional, and the service was fast and friendly.

07 June 2025

M

Mia Thompson

The product is fantastic! The quality stands out, and the service team was very helpful throughout.

04 June 2025

C

Charlotte Mitchell

This product is wonderful! The quality is high, and the customer service team excelled in their support.

17 May 2025