Air Cooled Steam Dump Condenser Factories in China - Top Manufacturers

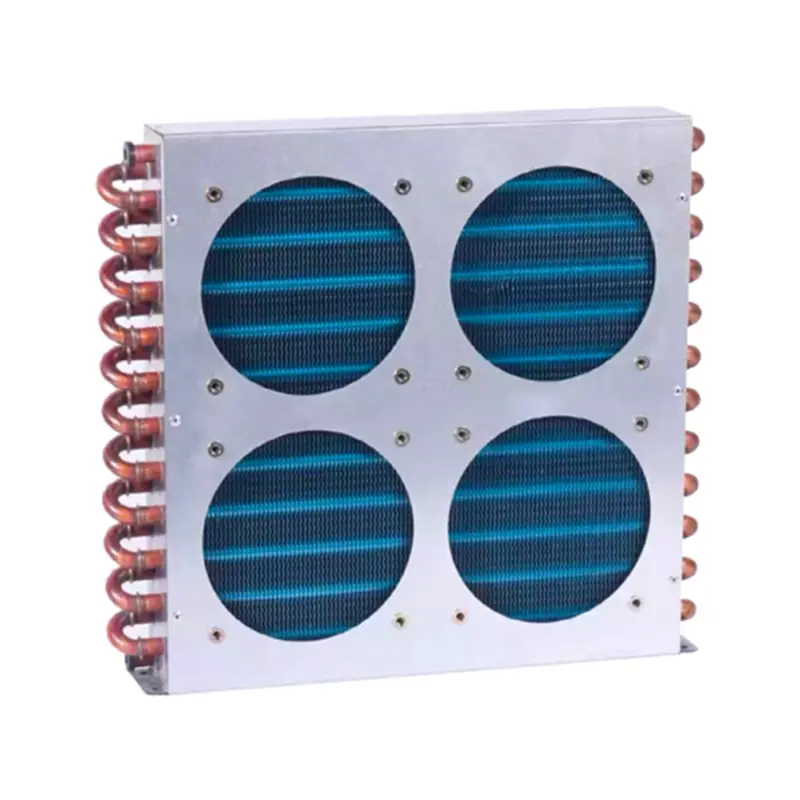

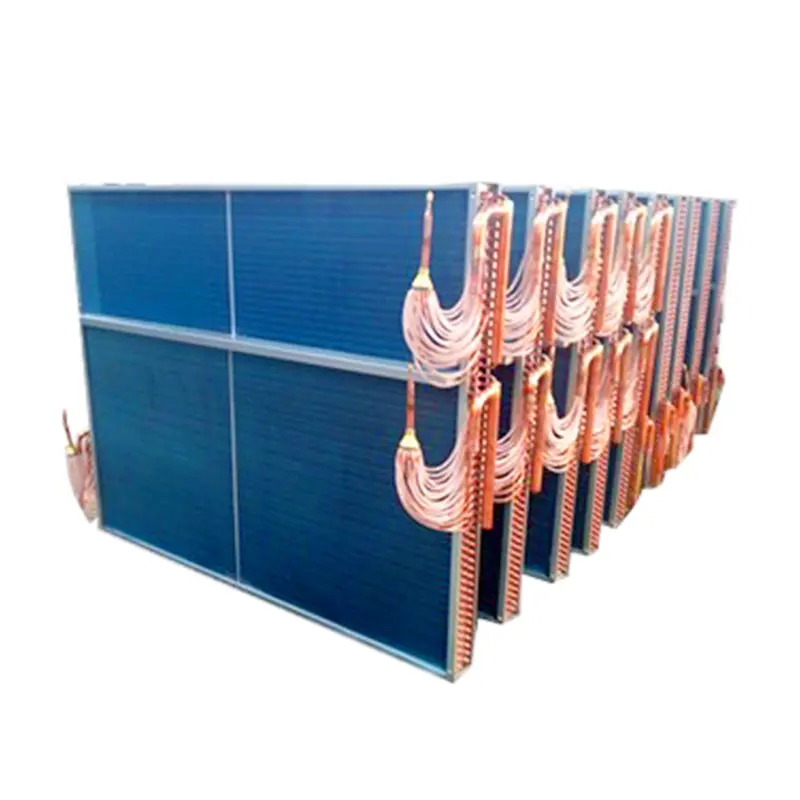

As a leader in the production of air cooled steam dump condensers, we understand the unique needs of industries seeking reliable solutions. Our factories in China are equipped with state-of-the-art technology, ensuring that every product meets rigorous quality standards. We take pride in being a trusted manufacturer and supplier of air cooled steam dump condensers, providing efficient and durable options for various applications

Best Practices For Air Cooled Steam Dump Condenser Factories From Concept to Delivery Dominates

When it comes to sourcing air-cooled steam dump condensers, understanding best practices from concept to delivery is essential for global buyers. At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on our decade-long commitment to innovation in the production of wire tube condensers and copper-aluminum fin heat exchangers. Our products are the backbone of various applications, including refrigerators, freezers, drinking fountains, and display cabinets. With a focus on cutting-edge technology and rigorous quality control, we ensure that our condensers not only meet but exceed the expectations of our clients worldwide. The journey from concept to delivery of air-cooled steam dump condensers involves meticulous planning and execution. It starts with understanding the specific requirements of each client and designing solutions tailored to their operational needs. By engaging in close collaboration with our clients throughout the design phase, we can optimize performance while ensuring energy efficiency and sustainability. Our state-of-the-art manufacturing processes utilize high-quality materials, ensuring that the final products are reliable and durable, which is crucial for end-users ranging from large-scale industries to small enterprises. Finally, an effective delivery system is vital for maintaining the integrity of the condensers during transit. At Ningbo Senjun, we employ advanced logistics strategies to ensure timely delivery while minimizing the risk of damage. Our global clients can rely on us not only for high-quality products but also for exceptional customer service and support throughout the purchasing process. By adhering to these best practices, we are committed to establishing long-lasting relationships with our clients and setting new standards in the air-cooled condenser market.

Best Practices For Air Cooled Steam Dump Condenser Factories From Concept to Delivery Dominates

| Best Practice | Description | Benefits | Implementation Stage |

|---|---|---|---|

| Design Efficiency | Utilizing advanced modeling software to refine design. | Reduces time and costs in production. | Concept |

| Quality Control | Implementing strict quality checks at every stage. | Ensures high standards of end products. | Manufacturing |

| Energy Efficiency | Incorporating energy-saving technologies into design. | Lowers operational costs significantly. | Design & Manufacturing |

| Supplier Collaboration | Building strong relationships with key suppliers. | Improves supply chain reliability. | Pre-Delivery |

| Testing & Validation | Conducting comprehensive tests before delivery. | Ensures product reliability and performance. | Delivery |

Uncovering Air Cooled Steam Dump Condenser Factories Manufacturer Service

I

Isabella White

This product is worth every penny! The quality is impressive, and the customer service team provided excellent support.

17 May 2025

E

Emma Allen

I love the quality of this product. The customer service representatives were also extremely helpful and proactive!

10 May 2025

I

Isabella Foster

Remarkable quality! The support staff is educated and attentive, making the entire process seamless.

28 May 2025

A

Alexander Johnson

I’m thoroughly impressed with this product! The quality is exceptional, and the support team was top-notch.

06 June 2025

A

Amelia King

The quality is excellent! The after-sales support staff were polite and very accommodating.

02 June 2025

S

Sofia Evans

A truly high-quality product! The customer service team was fantastic and resolved my issues quickly.

20 June 2025