Wholesale Suppliers and Manufacturers of 4 Components of Refrigeration Factory

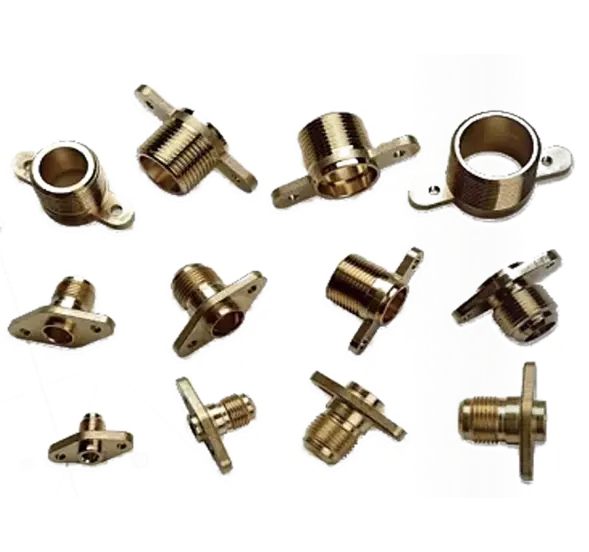

When it comes to understanding the 4 Components Of refrigeration Factory, I’ve got you covered. As someone who’s worked closely with top manufacturers in China, I know how crucial these components are for effective refrigeration systems. Whether you’re sourcing from trusted suppliers or diving into specs, let’s break it down, The four essential components include the compressor, condenser, expansion valve, and evaporator. Each plays a vital role in ensuring optimum performance and energy efficiency. I’ve seen how Ningbo Senjun New Materials Co., Ltd. excels in producing high-quality parts that meet international standards and can enhance the reliability of your refrigeration setups, By choosing the right supplier, you can ensure your factory’s needs are met while maintaining quality and cost-efficiency. If you’re ready to elevate your refrigeration projects, understanding these key parts is the first step toward making informed decisions. Let's ensure your business stays cool in every sense!

Key Steps to Choosing 4 Components Of Refrigeration Factory Products Your End-to-End Solution

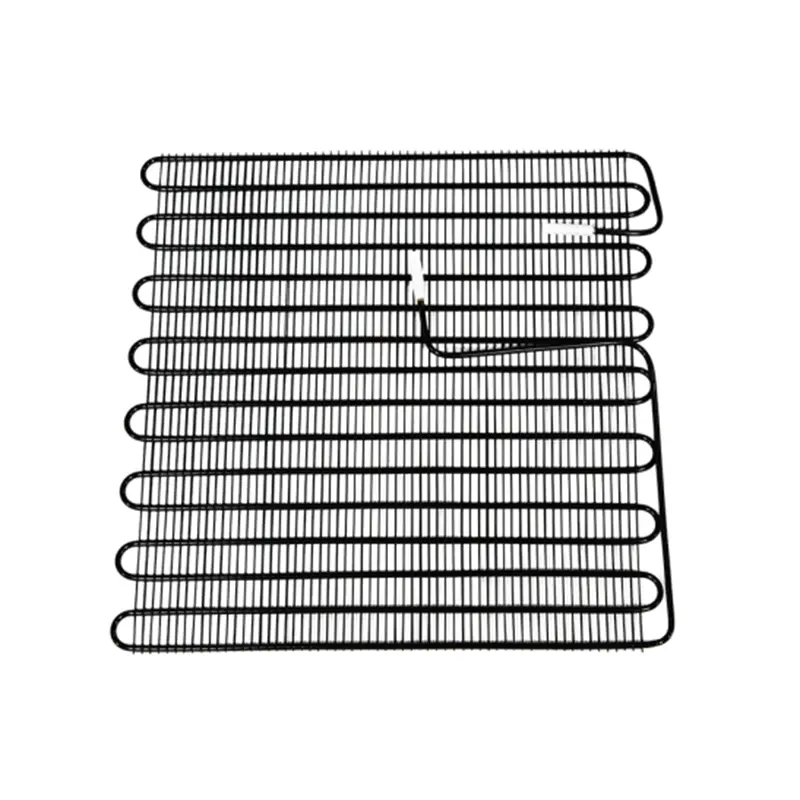

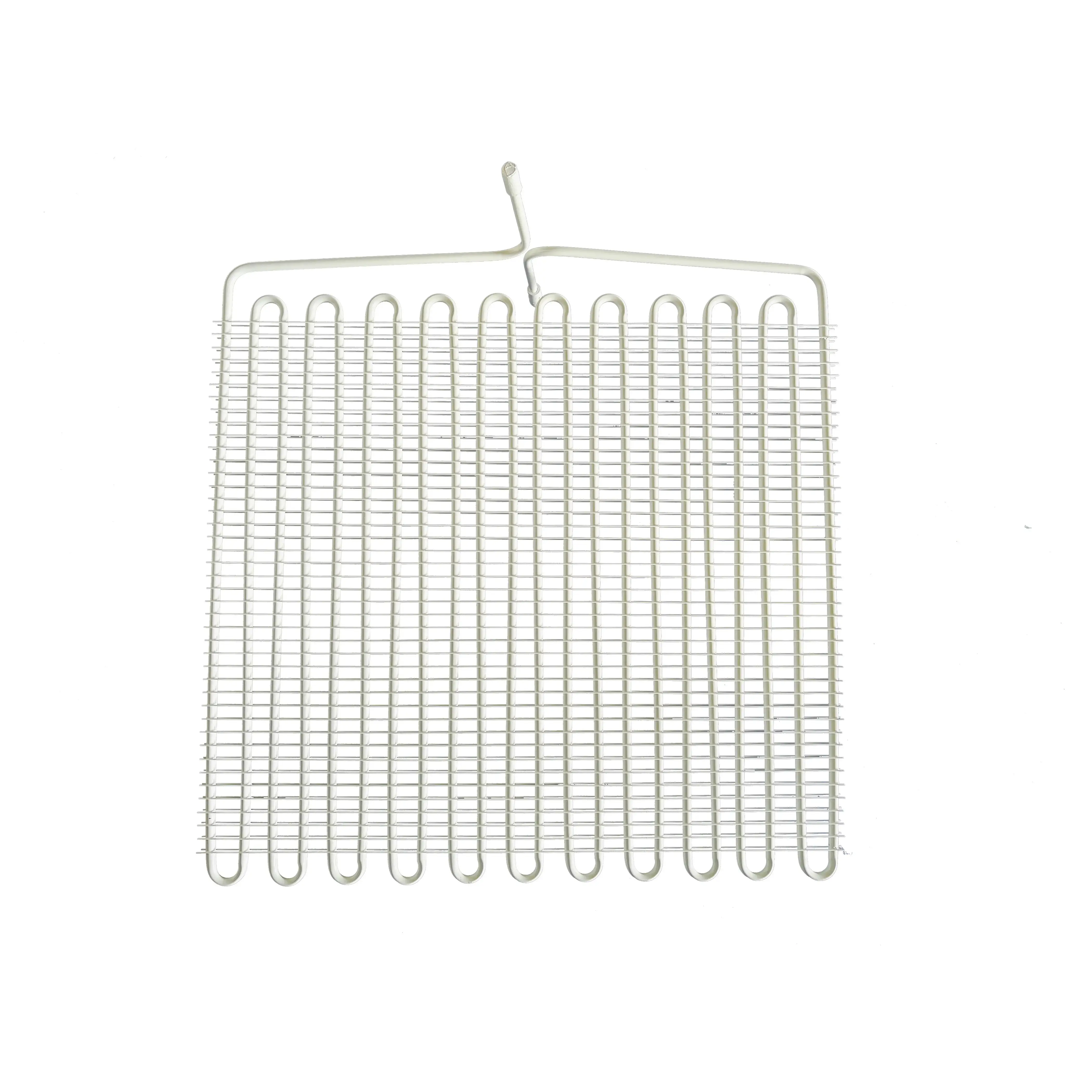

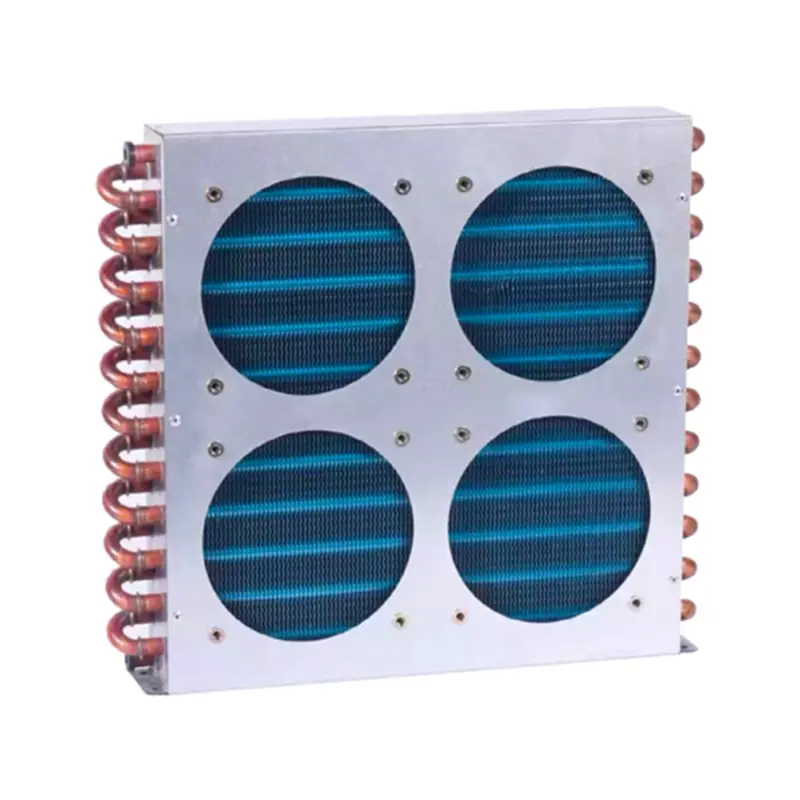

When sourcing refrigeration factory products, it's crucial to navigate the myriad of options available in the market. At Ningbo Senjun New Materials Co., Ltd., we understand that making informed decisions is key for global buyers. Since our inception in 2010, we have specialized in the research and production of wire tube condensers and copper aluminum fin heat exchangers for a variety of applications including refrigerators, freezers, drinking fountains, and display cabinets. To simplify your selection, here are four essential components to consider. First, evaluate the thermal performance. High-efficiency condensers and heat exchangers significantly impact energy consumption and product longevity. Our advanced designs ensure optimal heat transfer, reducing operational costs while maintaining high performance. Second, examine the durability of materials used. Products manufactured with high-quality materials like aluminum and copper not only enhance efficacy but also withstand varying environmental conditions, thus ensuring a longer product life cycle. Lastly, consider customization options. Every refrigeration application has unique requirements, and having the flexibility to tailor products can help meet specific needs. At Ningbo Senjun, we are dedicated to providing end-to-end solutions, working closely with our clients to deliver customized products that cater to their operational demands. With our extensive experience and commitment to innovation, you can trust us to be your reliable partner in the global refrigeration market.

Key Steps to Choosing 4 Components Of Refrigeration Factory Products Your End-to-End Solution

| Component | Key Features | Considerations | Cost Estimate ($) |

|---|---|---|---|

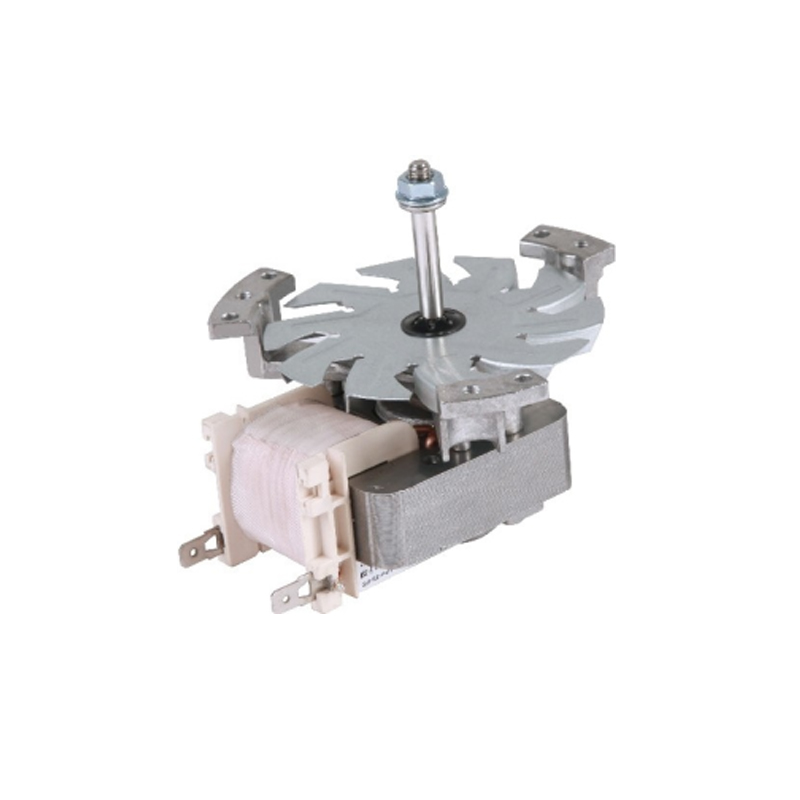

| Compressor | Energy Efficient, Low Noise | Size, Power Requirements | 500 - 1500 |

| Evaporator | Compact Design, Durable | Airflow Rate, Cooling Capacity | 300 - 1200 |

| Condenser | High Efficiency, Corrosion Resistant | Installation Space, Maintenance | 400 - 1300 |

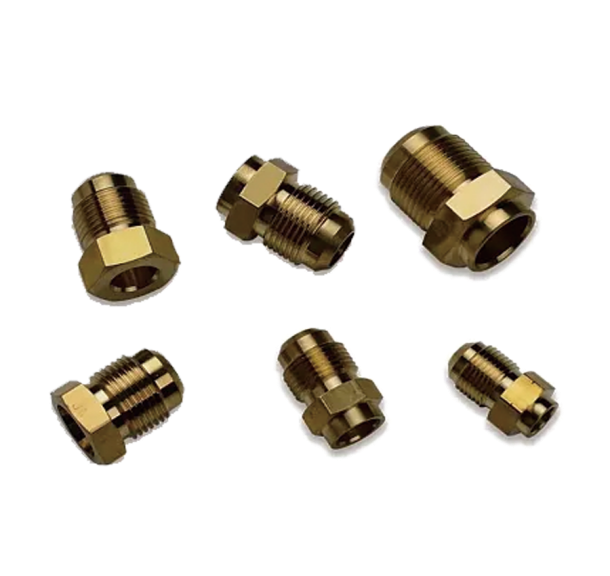

| Expansion Valve | Precision Control, Robust Construction | Compatibility, Flow Rate | 50 - 200 |

Reasons to Choose 4 Components Of Refrigeration Factory Application Factory

N

Noah Wright

The quality of the product is excellent, and the customer service was very professional. I highly recommend them!

15 June 2025

O

Owen Cooper

The quality of this product is top-notch! The after-sales service was quick and highly professional.

26 June 2025

O

Olivia White

Very high quality. The support team was quick to assist and very knowledgeable.

26 May 2025

A

Ava Nguyen

Amazing quality and superb service! The support team was incredibly knowledgeable.

15 May 2025

L

Liam Smith

This product exceeded all my expectations! Outstanding quality and very knowledgeable support team.

12 May 2025

B

Brian James

The craftsmanship is remarkable! The after-sales service was quick and thorough.

28 May 2025