Wire Tube Condenser from China: Top Factories & Manufacturers

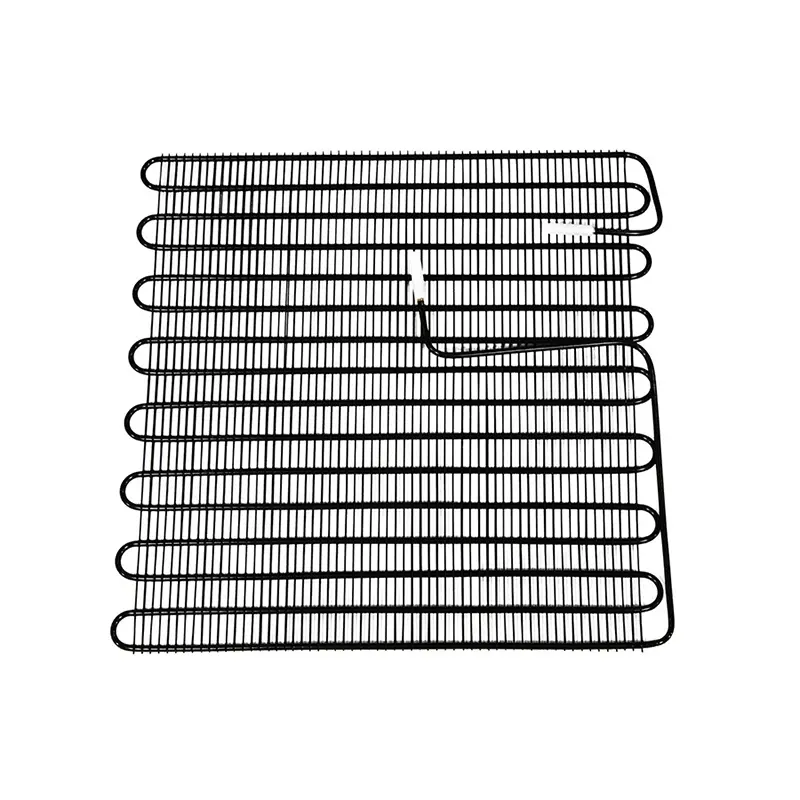

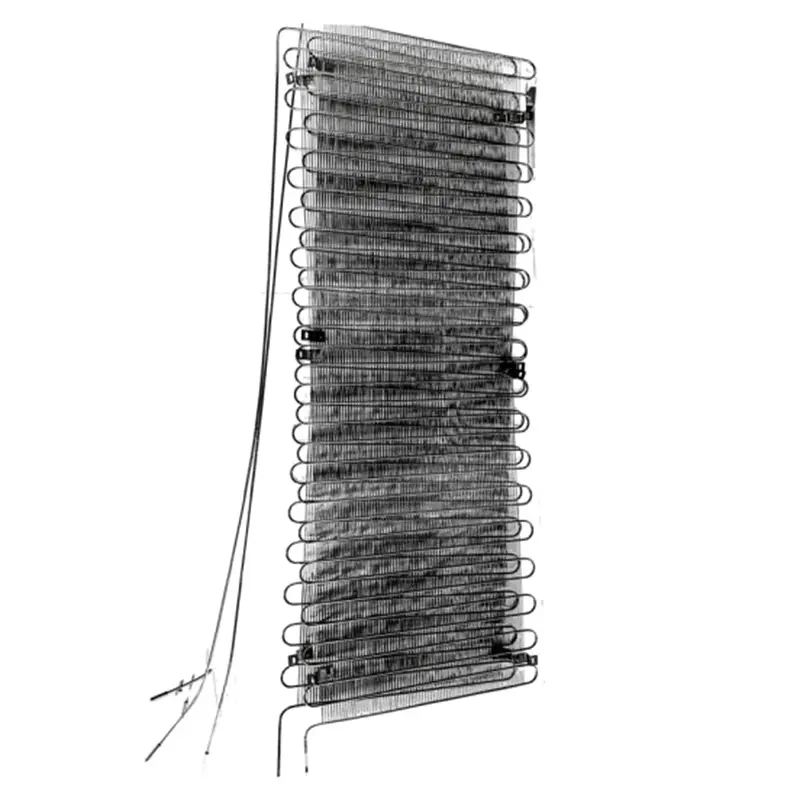

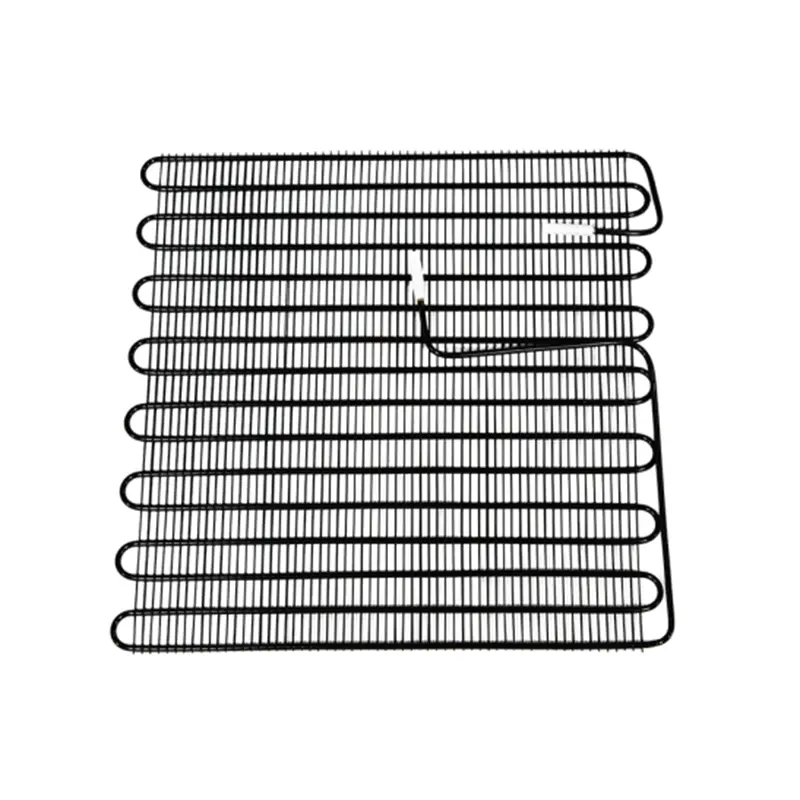

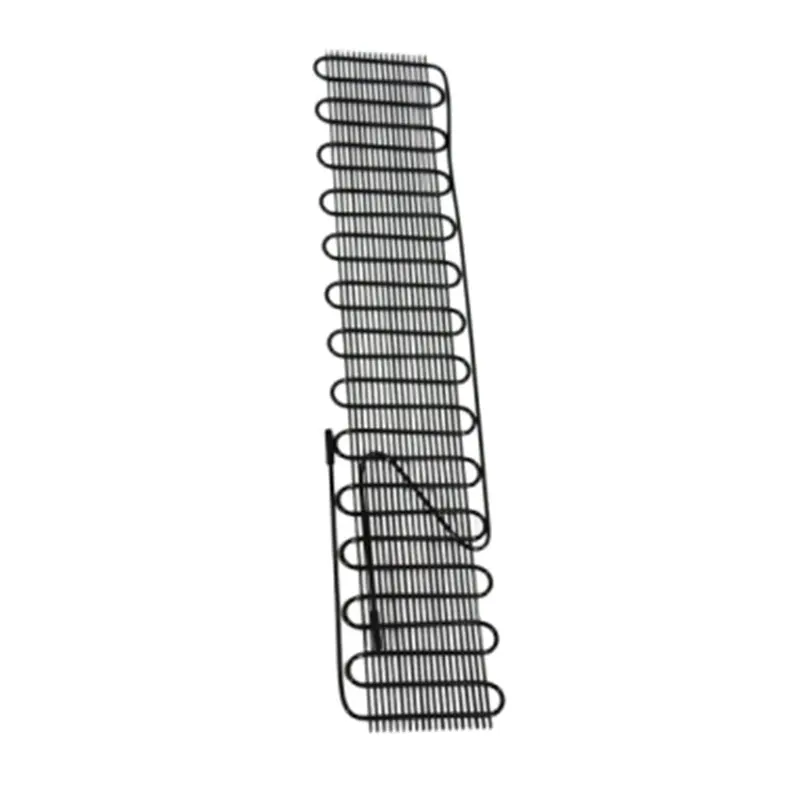

Ningbo Senjun New Materials Co., Ltd. offers cutting-edge Wire Tube Condensers designed for maximum efficiency and durability. These condensers are engineered to optimize heat exchange processes in various applications, ensuring superior performance in HVAC Systems and industrial cooling solutions, Crafted from high-quality materials, the Wire Tube Condenser features a unique design that promotes enhanced airflow and heat dissipation, leading to lower energy consumption and reduced operational costs. The compact size allows for easy installation in limited spaces without compromising efficiency, Our commitment to innovation and quality means that each Wire Tube Condenser undergoes rigorous testing to meet industry standards, ensuring reliability and longevity. Ideal for both residential and commercial use, these condensers are a perfect choice for energy-conscious businesses and homeowners alike. Experience the difference that advanced materials and thoughtful engineering can make with Ningbo Senjun’s Wire Tube Condensers, and elevate your cooling systems to the next level

7 Key Tips To Wire Tube Condenser Industry Giant Outperforms the Competition

In the competitive landscape of wire tube condenser manufacturing, Ningbo Senjun New Materials Co., Ltd. stands out as an industry leader since its establishment in 2010. Our commitment to innovation and excellence in the research, development, and production of wire tube condensers and copper aluminum fin heat exchangers has allowed us to forge strong connections with global buyers looking for reliable cooling solutions for refrigerators, freezers, drinking fountains, and display cabinets. To outperform the competition, we emphasize several key strategies. First, our dedication to high-quality materials ensures that our products not only meet but exceed industry standards, providing durability and outstanding thermal performance. Second, our state-of-the-art manufacturing processes allow for efficiency without compromising the precision necessary for optimal heat exchange. Third, our skilled R&D team continuously innovates, adapting to market trends and customer needs, enabling us to offer customized solutions that enhance energy efficiency and operational effectiveness. By choosing Ningbo Senjun, global purchasers gain not only access to superior products but also a partner dedicated to sustainability and customer satisfaction. Our proactive approach to meeting client specifications and our reliable service make us a preferred choice in the wire tube condenser industry, ensuring that your business remains competitive while benefiting from cutting-edge technology and unmatched expertise.

7 Key Tips To Wire Tube Condenser Industry Giant Outperforms the Competition

| Tip | Description | Impact | Implementation Difficulty |

|---|---|---|---|

| Optimize Production Efficiency | Streamline manufacturing processes to reduce waste and increase output. | Increased Output by 20% | Medium |

| Invest in R&D | Focus on innovative technologies and product improvements. | Enhanced Product Performance | High |

| Expand Customer Support | Offer comprehensive technical assistance to boost customer satisfaction. | Customer Retention Rate Increased by 15% | Medium |

| Enhance Supply Chain Management | Optimize logistics to ensure timely delivery of components. | Reduced Lead Times by 25% | High |

| Leverage Digital Marketing | Utilize online platforms to increase brand visibility and reach. | Website Traffic Increased by 30% | Low |

| Adopt Sustainable Practices | Implement eco-friendly procedures to appeal to conscious consumers. | Improved Brand Image | Medium |

| Build Strong Partnerships | Collaborate with suppliers and distributors for mutual benefit. | Better Pricing and Service Flexibility | Medium |

Discovering Wire Tube Condenser Supplier More Than a Supplier - A Partner

J

James Wilson

Exceptional quality! The after-sales service representatives were responsive and educated, making me feel valued.

18 June 2025

M

Maddison Reed

Fantastic quality and superb support! The after-sales team really knows their stuff.

15 June 2025

E

Ella Hernandez

Absolutely wonderful quality! The support team was approachable and very helpful throughout.

08 June 2025

L

Lily Carter

Incredible quality with a flawless design! The after-sales team was very supportive and attentive.

16 May 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025

D

David Lee

Outstanding product! The support team addressed all my concerns with expertise and care.

04 June 2025