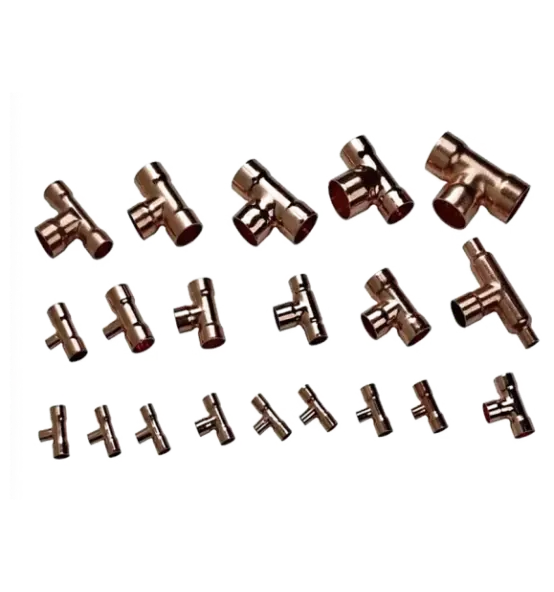

Wholesale Tank Joint Components Supplier | Quality Parts & Bulk Deals

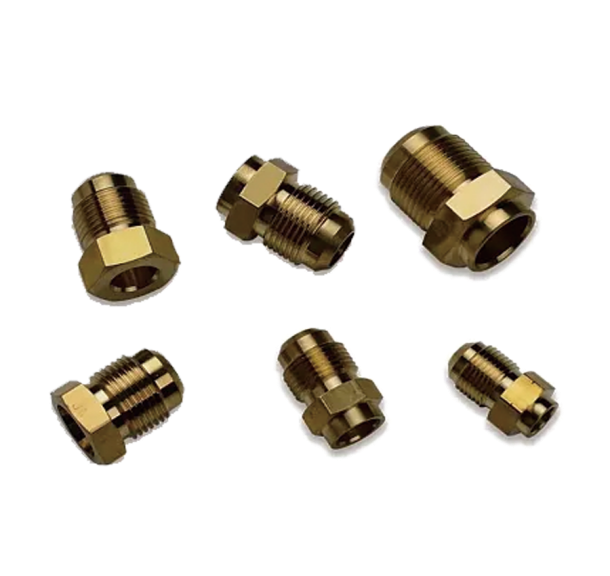

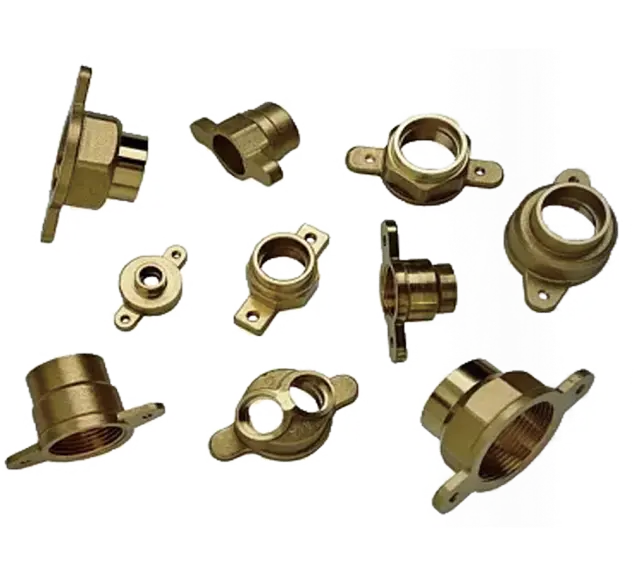

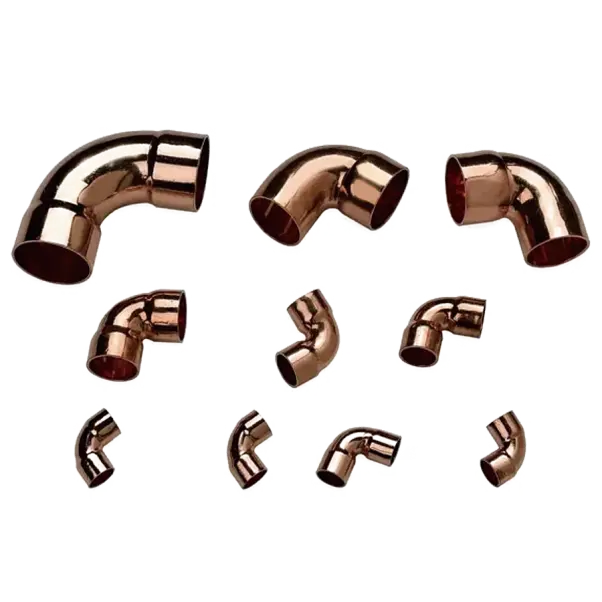

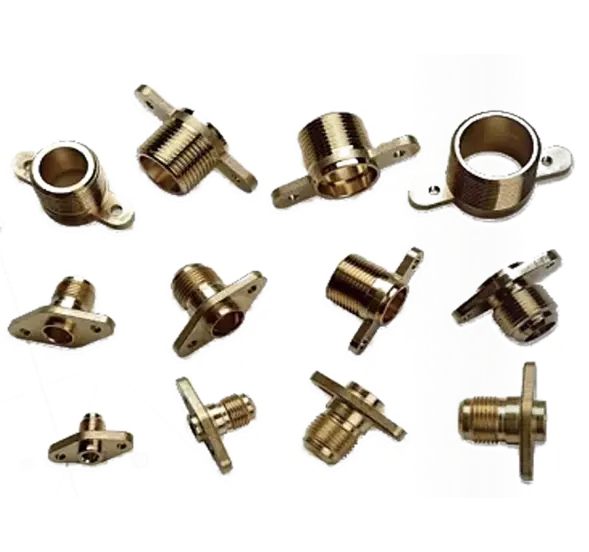

Ningbo Senjun New Materials Co., Ltd. specializes in high-quality Tank Joint Components designed to enhance the durability and efficiency of your tank systems. Our products are engineered to withstand extreme pressure and temperature variations, ensuring safe and reliable operation in a variety of applications, including chemical storage, oil and gas, and water treatment, Crafted from premium materials, our tank joint components feature innovative designs that minimize leakage and provide seamless integration with existing systems. With a focus on precision engineering, each component undergoes rigorous testing to ensure optimal performance and longevity, Our commitment to customer satisfaction drives us to provide tailored solutions and exceptional service. Whether you require standard components or custom-designed solutions, our expert team is ready to assist you in finding the perfect fit for your needs. Choose Ningbo Senjun New Materials Co., Ltd. for reliable tank joint components that stand the test of time and meet the highest industry standards

Practical Strategies for Tank Joint Components Manufacturer Where Service Meets Innovation

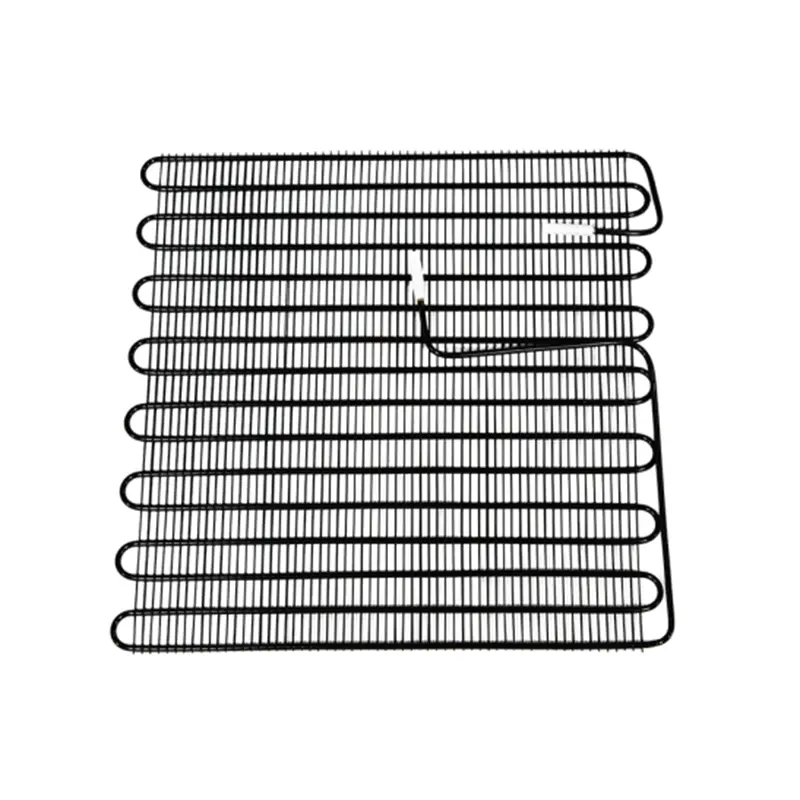

At Ningbo Senjun New Materials Co., Ltd., we understand that in today's fast-paced industrial landscape, staying ahead requires not just innovation in products but also excellence in service. Since our establishment in 2010, we have dedicated ourselves to developing and manufacturing high-quality wire tube condensers and copper-aluminum fin heat exchangers. Our products are integral to appliances such as refrigerators, freezers, drinking fountains, and display cabinets, making them vital for various sectors globally. To cater to the needs of our global procurement partners, we employ practical strategies that marry service and innovation. Our research and development team continuously tests new materials and designs, ensuring that our offerings are not only efficient and reliable but also meet increasingly stringent regulatory standards. Through real-time customer feedback and a commitment to responsive service, we adapt our production techniques to better satisfy the unique demands of our clients in different regions. Moreover, our commitment to sustainability drives us to innovate processes that reduce waste and energy consumption, which is increasingly important in global supply chains. As we forge partnerships with manufacturers and distributors worldwide, we aim to provide not just products, but comprehensive solutions that enhance operational efficiency and contribute to environmental stewardship. By focusing on both product excellence and superior service, Ningbo Senjun is poised to be your trusted partner in the tank joint components market.

Practical Strategies for Tank Joint Components Manufacturer Where Service Meets Innovation

| Component Type | Material | Manufacturing Process | Innovation Aspect | Service Strategy |

|---|---|---|---|---|

| Joint Flange | Carbon Steel | CNC Machining | Improved Stress Resistance | 24/7 Customer Support |

| Welding Neck | Stainless Steel | Automated Welding | Corrosion-Resistant Coating | Flexible Delivery Options |

| Socket Weld | Alloy Steel | Precision Casting | Enhanced Durability | On-Site Consultations |

| Blind Flange | Ductile Iron | Sand Casting | Lightweight Design | Warranty and After-Sales Service |

| Gate Valve | Brass | Forging | Smart Valve Technology | Technical Support Training |

Step-by-Step Guide To Tank Joint Components Delivers Unmatched Quality Manufacturers You Can Rely On

S

Sophia Martinez

I’m thrilled with this product! The quality is outstanding, and the customer service really goes above and beyond.

27 June 2025

K

Kevin Walker

This product is fantastic! The quality is terrific, and the after-sales service was both prompt and professional.

16 June 2025

O

Owen Cooper

The quality of this product is top-notch! The after-sales service was quick and highly professional.

26 June 2025

J

James Adams

A product that truly stands out! Quality is superb and the customer service team is highly professional.

04 July 2025

E

Ethan Fisher

Impressive quality! The after-sales support team was attentive and provided great service.

15 June 2025

L

Liam Carter

Amazing quality! The support team was friendly and responsive to all my inquiries.

23 June 2025