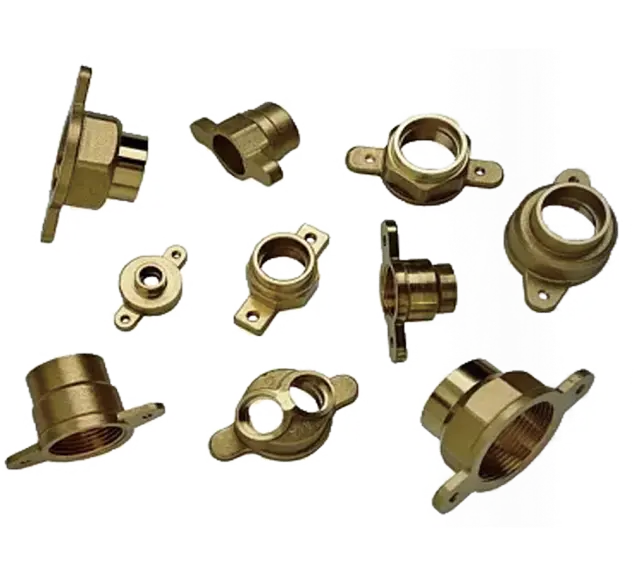

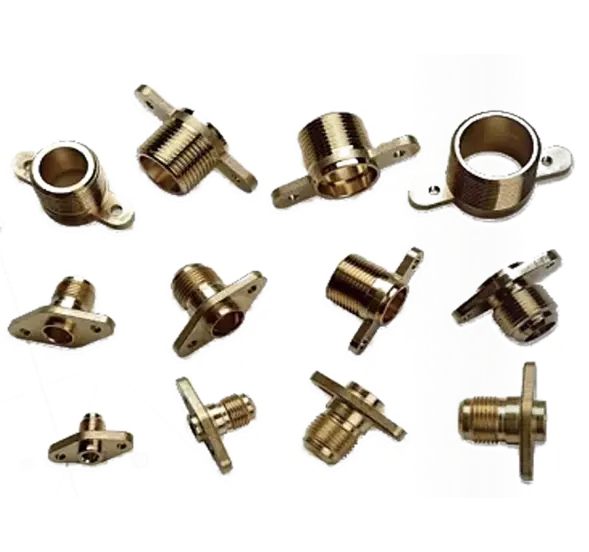

Robust Brass Flange Fittings for Pipe Systems - China Manufacturer

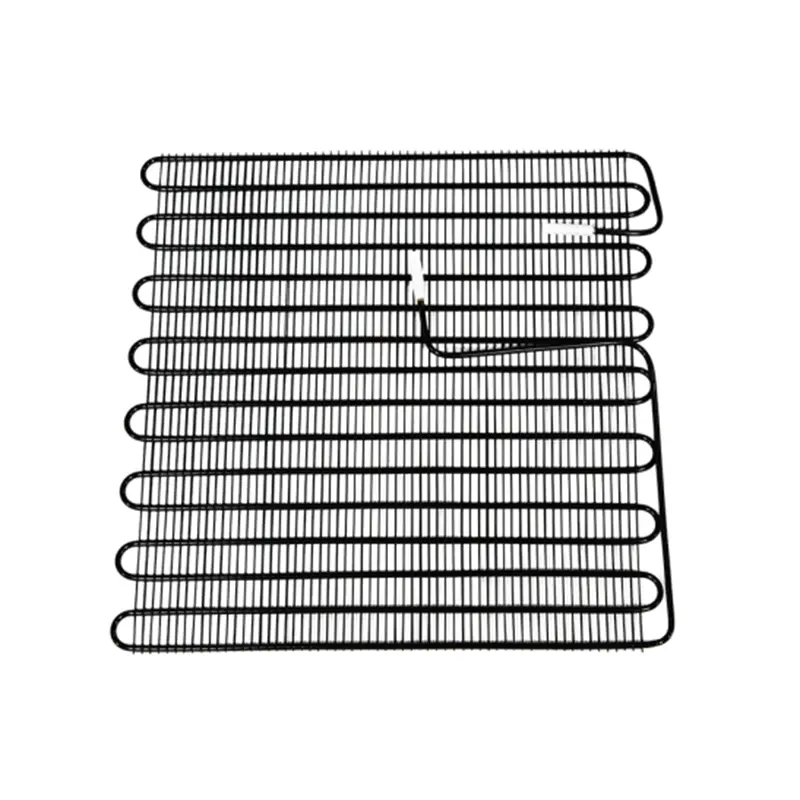

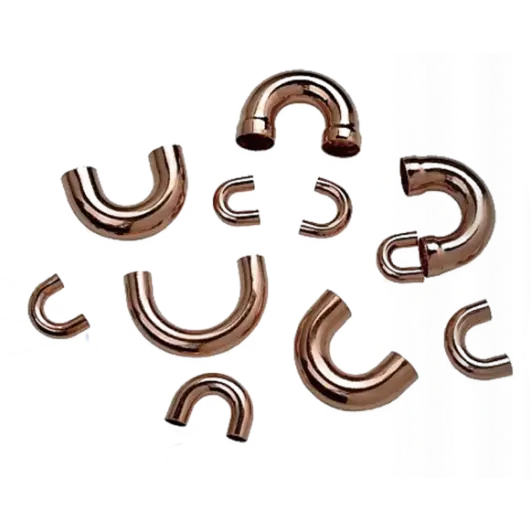

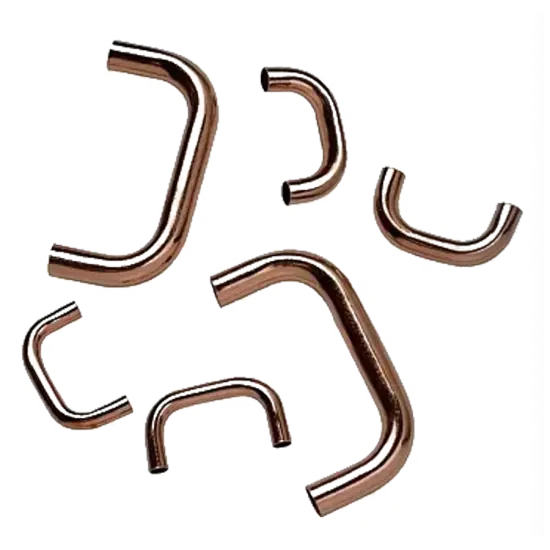

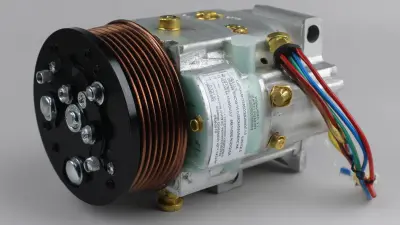

Ningbo Senjun New Materials Co., Ltd. presents an exceptional range of robust Brass Flange Fittings designed specifically for pipe systems. Engineered for durability and reliability, these fittings offer superior corrosion resistance and strength, making them ideal for a variety of applications, including plumbing, HVAC, and industrial settings, Crafted from high-quality brass, these flange fittings ensure a secure and leak-proof connection, enhancing the overall performance of your piping system. The precision engineering and innovative design guarantee optimal flow characteristics and easy installation, reducing downtime and maintenance costs, With a commitment to quality and customer satisfaction, our brass flange fittings undergo rigorous testing to meet industry standards. Choose Ningbo Senjun New Materials Co., Ltd. for your piping needs and experience the perfect blend of functionality and long-lasting performance. Whether for new installations or repairs, our robust brass fittings are the trusted choice for professionals seeking reliability and excellence in their pipe systems

In-Depth Analysis of Methods Robust Brass Flange Fittings for Pipe Systems Exceeds Industry Benchmarks Supplies the World’s Top Brands

In today's competitive market, the demand for high-quality plumbing and heating solutions has never been greater. At Ningbo Senjun New Materials Co., Ltd., we pride ourselves on our extensive research and development efforts that have led to the creation of robust brass flange fittings for various pipe systems. These fittings not only meet but exceed industry benchmarks, providing resilient and reliable solutions favored by the world’s top brands. Our brass flange fittings, engineered with precision, ensure optimal performance in diverse applications including refrigerators, freezers, drinking fountains, and display cabinets. Their durability and resistance to corrosion make them a preferred choice for global buyers looking for longevity and efficiency. By investing in cutting-edge technology and adhering to strict quality controls, we deliver products that enhance system reliability while reducing maintenance costs. As we continue to expand our presence in international markets, we invite global procurers to experience the exceptional quality and performance of our brass flange fittings. Partner with Ningbo Senjun New Materials Co., Ltd. to meet your supply needs, secure high-quality components, and elevate your product offerings in the competitive landscape of refrigeration and HVAC systems.

In-Depth Analysis of Methods Robust Brass Flange Fittings for Pipe Systems Exceeds Industry Benchmarks Supplies the World’s Top Brands

| Dimension (Inches) | Pressure Rating (PSI) | Material Grade | Corrosion Resistance (%) | Industry Compliance |

|---|---|---|---|---|

| 1 | 150 | DZR Brass | 95 | ASTM B16.24 |

| 1.5 | 150 | Lead-Free Brass | 90 | NSF 61 |

| 2 | 300 | C36000 Brass | 85 | ISO 9001 |

| 2.5 | 300 | C37700 Brass | 88 | ASME B16.5 |

| 3 | 400 | DHP Brass | 92 | API 6A |

Proven Methods To Robust Brass Flange Fittings for Pipe Systems Global Reach Service

T

Thomas Brown

I can’t praise this product enough! The quality is remarkable, and the after-sales service has been incredibly supportive.

12 June 2025

E

Ella Gomez

This product has great durability! The after-sales support was very professional and attentive.

02 June 2025

Z

Zoe Rivera

I love the quality! The support team was really friendly and addressed all my questions effectively.

05 June 2025

O

Owen Cooper

The quality of this product is top-notch! The after-sales service was quick and highly professional.

26 June 2025

M

Mia Howard

Unbelievable quality! The customer service team went the extra mile to ensure my satisfaction.

24 May 2025

C

Chloe Hill

What a fantastic purchase! The product quality is exceptional, and the customer service was responsive and professional.

26 June 2025