Top Inline Desiccant Filter Manufacturers in China | Trusted Suppliers

As a leading inline Desiccant Filter manufacturer, I understand the needs of businesses looking for reliable and high-quality solutions. Our filters are designed to maintain optimal performance in various applications, ensuring moisture control and extending the life of your equipment, By choosing our products, you're opting for durability and efficiency, backed by our commitment to quality. We cater to wholesalers and factories alike, providing competitive pricing without compromising on performance. With our experience and expertise at Ningbo Senjun New Materials Co., Ltd., I ensure that our inline desiccant filters meet the highest standards in the industry, Whether you're sourcing components for production or need a dependable supplier, our range of products can fulfill your requirements. Let’s work together to enhance your operations with our superior desiccant filters. Reach out today and experience the difference our manufacturing capabilities can make for your business!

Tips & Tricks for Inline Desiccant Filter Manufacturers Where Service Meets Innovation Your End-to-End Solution

In today's fast-paced industrial landscape, inline desiccant filter manufacturers are increasingly focusing on integrating innovative solutions with exceptional service. At Ningbo Senjun New Materials Co., Ltd., our commitment to research and development in wire tube condensers and copper aluminum fin heat exchangers sets us apart. Since our establishment in 2010, we have been dedicated to providing end-to-end solutions for various applications, including refrigerators, freezers, drinking fountains, and display cabinets. Understanding the needs of global buyers, our products are engineered to enhance efficiency and durability while minimizing maintenance. We leverage advanced technology and state-of-the-art manufacturing processes to create filters that not only perform optimally but also align with sustainability goals. Our inline desiccant filters are designed to provide superior moisture control, significantly extending the lifespan of your equipment. By choosing Ningbo Senjun, you gain access to robust, innovative products backed by a service-oriented approach that prioritizes your success. In a market driven by innovation, the synergy of service and product excellence is key. We emphasize collaboration with our clients, ensuring that your specific requirements are at the forefront of our product development. Whether you are looking for standard solutions or customized designs, our team is dedicated to delivering exceptional value to meet your needs. Trust Ningbo Senjun as your reliable partner in sourcing inline desiccant filters, and experience the difference that innovation coupled with outstanding service can make for your business.

Tips & Tricks for Inline Desiccant Filter Manufacturers Where Service Meets Innovation Your End-to-End Solution

| Dimension | Value | Comments |

|---|---|---|

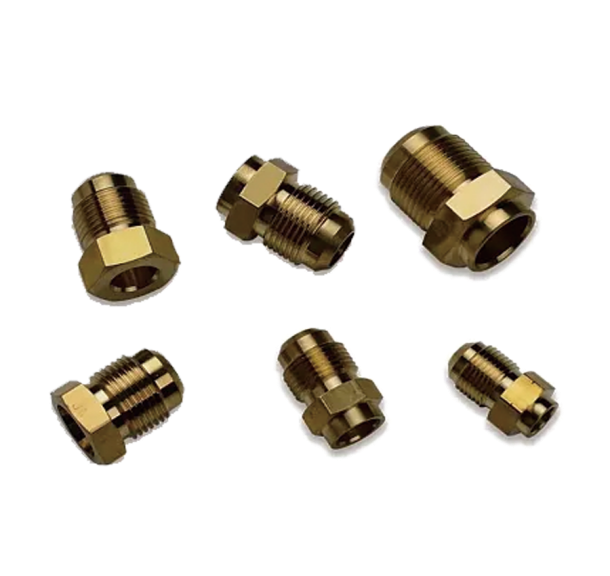

| Filter Type | Inline Desiccant Filter | Used for moisture control |

| Material | Aluminum | Lightweight and corrosion resistant |

| Max Working Pressure | 150 PSI | Safety measures needed |

| Operating Temperature | -40°F to 150°F | Wide range for various applications |

| Filter Capacity | 500 CFM | Suitable for small to medium systems |

| Maintenance Schedule | Every 6 Months | Ensure optimal performance |

| Warranty Period | 2 Years | Peace of mind for manufacturers |

Uncovering Inline Desiccant Filter Manufacturers Trusted by Pros Dominates

N

Noah Wright

The quality of the product is excellent, and the customer service was very professional. I highly recommend them!

15 June 2025

E

Ella Gomez

This product has great durability! The after-sales support was very professional and attentive.

02 June 2025

A

Aiden Anderson

Superb craftsmanship! The customer service was impressive and went above and beyond.

10 June 2025

A

Alexander Johnson

I’m thoroughly impressed with this product! The quality is exceptional, and the support team was top-notch.

06 June 2025

A

Ava Cooper

I am thoroughly satisfied! The product quality is exceptional, and the customer service was very professional.

14 May 2025

E

Ethan Taylor

Fantastic durability and quality! The after-sales team was extremely professional and insightful.

08 June 2025