Wholesale Inducer Motor Furnace - Top Manufacturers & Quality Solutions

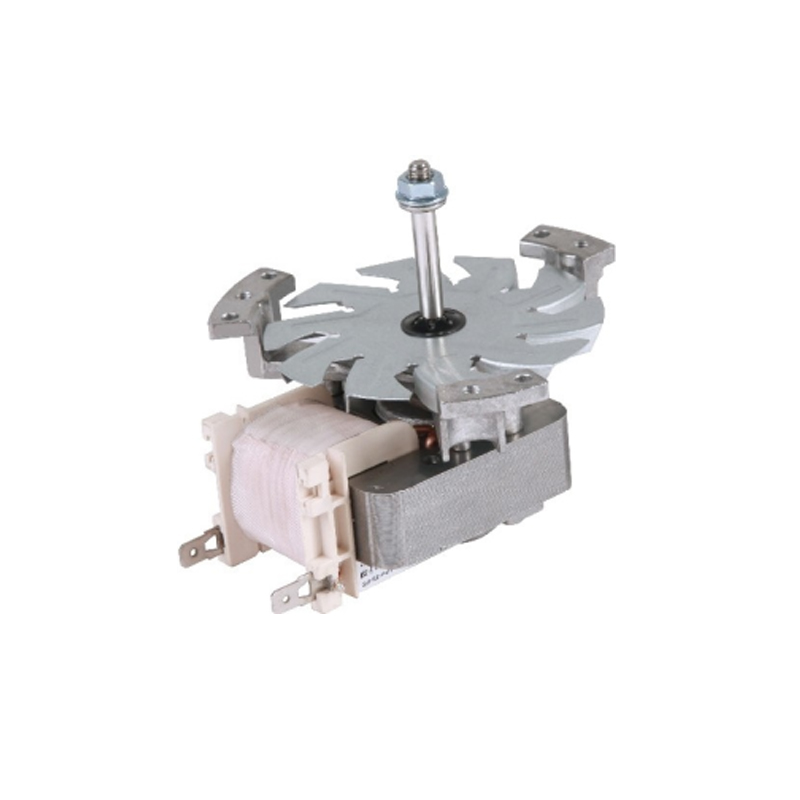

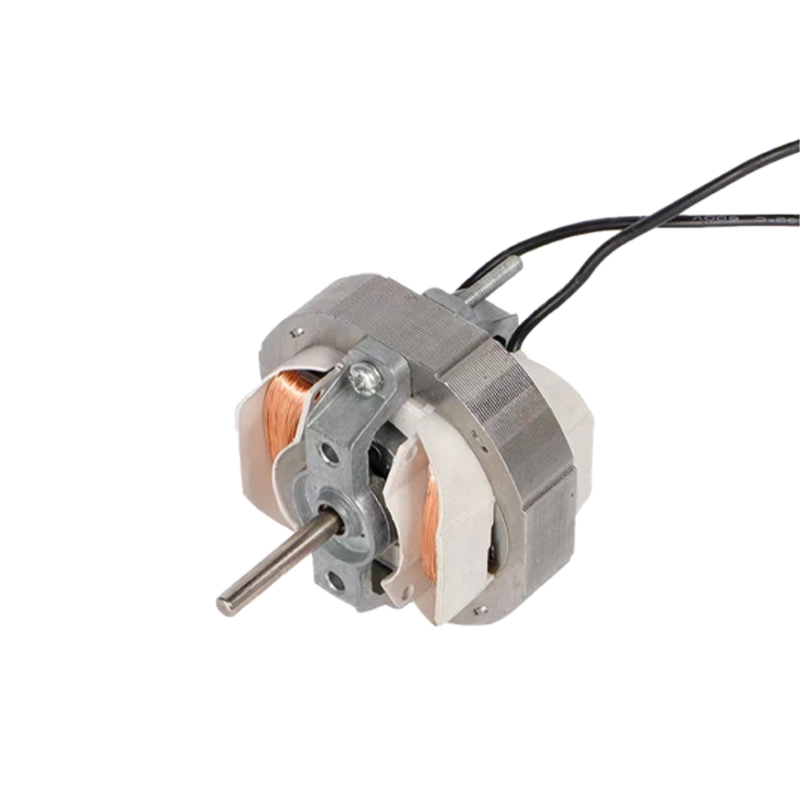

Discover the advanced Inducer Motor Furnace, a groundbreaking innovation from Ningbo Senjun New Materials Co., Ltd. This state-of-the-art furnace leverages electromagnetic induction technology to deliver efficient and precise heating for a variety of industrial applications. With its robust design and superior performance, it is engineered to optimize energy usage while ensuring consistent Temperature Control, The Inducer Motor Furnace is ideal for processes requiring high temperatures and rapid heating. Its user-friendly interface allows for easy operation and monitoring, making it suitable for both small-scale operations and large industrial facilities. Safety features are integrated to protect users and equipment alike, ensuring a reliable working environment

Methods To choose Inducer Motor Furnace Trusted by Pros Custom Solutions,

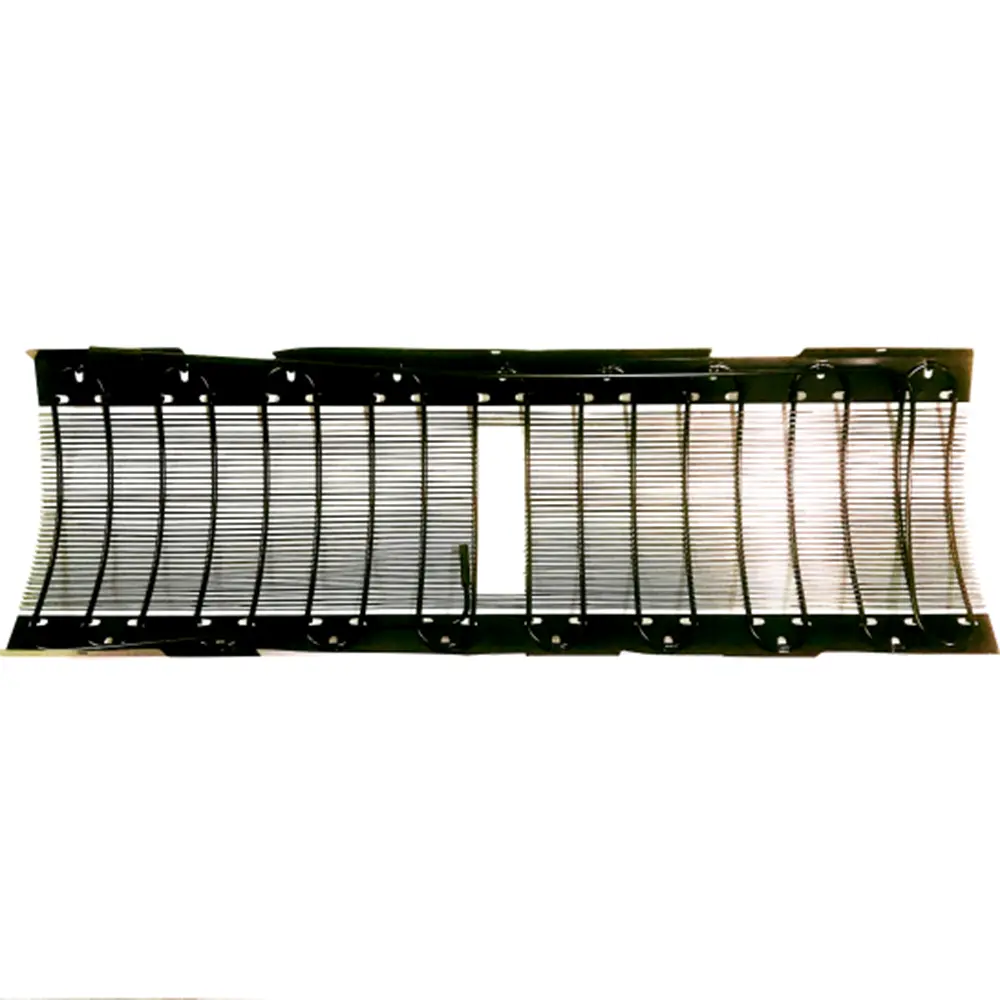

When selecting an inducer motor furnace, the insights from industry experts can lead you to custom solutions that enhance both efficiency and performance. At Ningbo Senjun New Materials Co., Ltd., we leverage over a decade of experience in developing advanced thermal management systems, including cutting-edge wire tube condensers and copper aluminum fin heat exchangers. Our commitment to innovation ensures that our products not only meet but exceed the demanding requirements of modern refrigeration and HVAC applications. Choosing the right inducer motor furnace is crucial for optimizing operational efficiency and reducing energy consumption. Professionals in the industry recommend focusing on a few key factors: the design quality, material selection, and compatibility with existing systems. At Senjun, we provide tailored solutions that address specific needs, whether for refrigerators, freezers, or display cabinets. By integrating state-of-the-art technologies and materials, we ensure that our heat exchangers offer superior performance and reliability. Collaborating with a well-established partner like Ningbo Senjun can greatly enhance your procurement strategy. Our team of experts is dedicated to delivering solutions that are not only reliable but also innovative, helping you stay ahead in a competitive market. Choose Senjun for your inducer motor furnace needs and experience the difference that trusted expertise can make in your operations.

Methods To Choose Inducer Motor Furnace Trusted by Pros Custom Solutions

| Criteria | Description | Pros' Recommendations |

|---|---|---|

| Motor Type | Choose between universal, AC, or DC motors based on your application. | AC motors are generally preferred for efficiency. |

| Furnace Capacity | Select a furnace with appropriate capacity for the material load. | Consider future scaling needs. |

| Energy Efficiency | Review energy consumption ratings of the furnace. | Look for high-efficiency models to save costs. |

| Material Compatibility | Ensure the furnace can handle the type of materials you will use. | Consult with manufacturers for specific material charts. |

| Control Options | Evaluate the control systems available, whether manual or digital. | Digital controls provide better precision. |

| Safety Features | Check for certifications and safety features included. | Prioritize models with advanced safety mechanisms. |

| Maintenance Requirements | Analyze the maintenance needs and ease of access for repairs. | Choose models designed for easy maintenance. |

| Cost | Compare the initial investment against operational costs. | Investing in quality often pays off long-term. |

Why Trust Inducer Motor Furnace Where Innovation Meets 2025 Factory-Direct Excellence

S

Scarlett Baker

I’m thoroughly impressed! The quality is remarkable, and the customer service team provided excellent support.

31 May 2025

A

Aiden Anderson

Superb craftsmanship! The customer service was impressive and went above and beyond.

10 June 2025

C

Carter Walker

Excellent product all around! The quality is phenomenal, and the support team was exceptionally helpful.

07 June 2025

M

Michael Perez

Incredible quality and service! The support team was friendly and efficient.

27 May 2025

D

David Lee

Outstanding product! The support team addressed all my concerns with expertise and care.

04 June 2025

C

Charlotte Mitchell

This product is wonderful! The quality is high, and the customer service team excelled in their support.

17 May 2025