High-Efficiency Chillers from Leading Manufacturers in China Factory

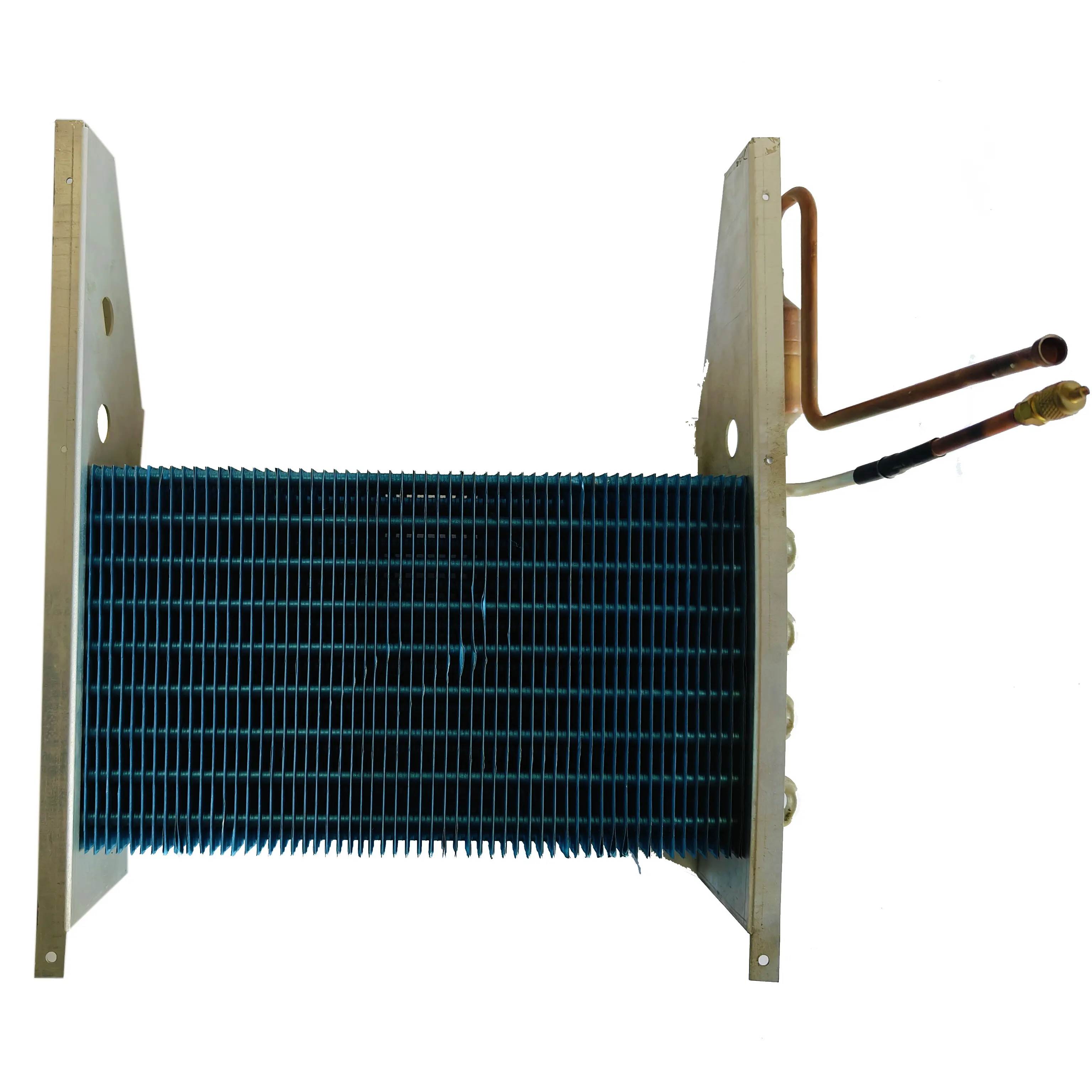

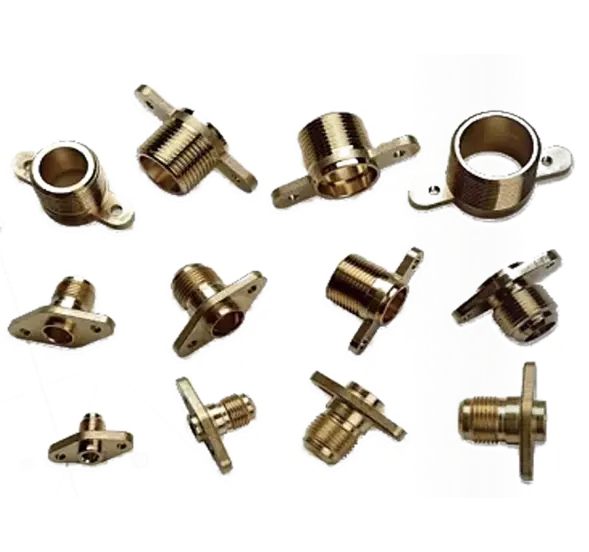

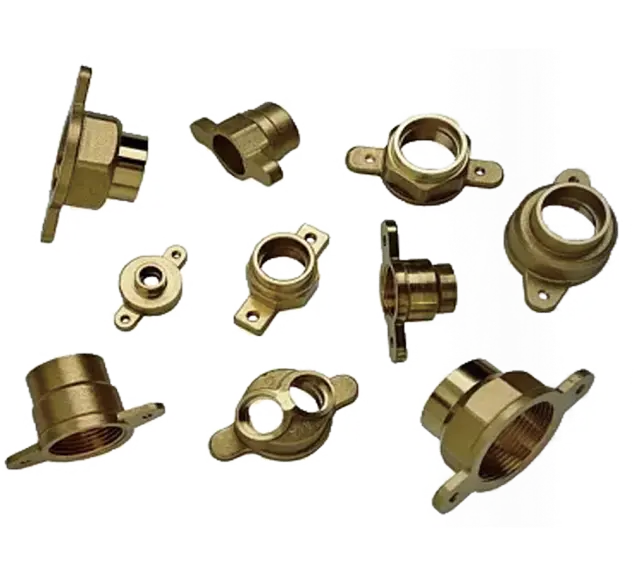

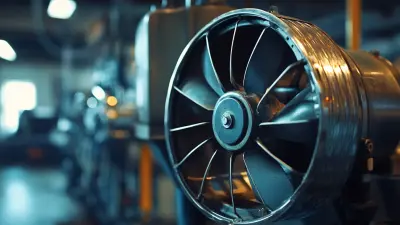

Ningbo Senjun New Materials Co., Ltd. proudly presents its cutting-edge High-Efficiency Chillers, designed to meet the increasing demands for energy efficiency and superior cooling performance in various industrial applications. These advanced chillers utilize state-of-the-art technology to optimize energy consumption, significantly reducing operational costs while enhancing overall performance, Engineered with precision, our High-Efficiency Chillers feature robust components that ensure reliability and longevity, making them ideal for processes that require consistent Temperature Control. The compact design allows for easy installation and integration into existing systems, while user-friendly controls provide seamless operation, Environmental considerations are also at the forefront of our design, with refrigerants that minimize greenhouse gas emissions, ensuring compliance with global standards. Whether for manufacturing, HVAC, or any other application, our High-Efficiency Chillers deliver unparalleled cooling efficiency and performance, positioning Ningbo Senjun New Materials Co., Ltd. as a trusted partner in sustainable industrial solutions. Experience the future of cooling technology with us

Tips & Tricks for High-Efficiency Chillers Industry Giant Service

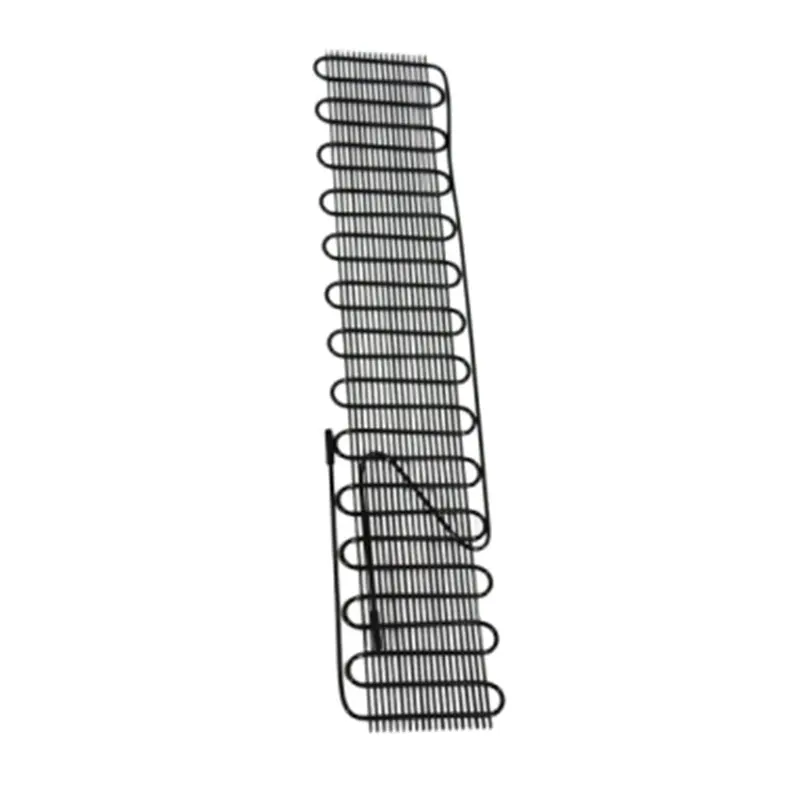

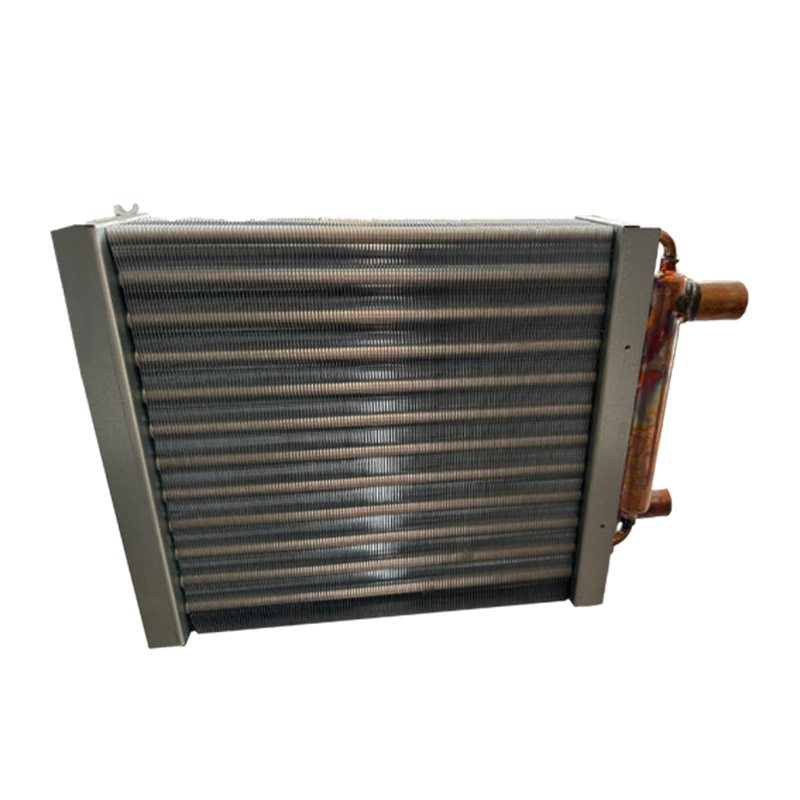

In the rapidly evolving chillers industry, maximizing efficiency is crucial for staying ahead in a competitive market. At Ningbo Senjun New Materials Co., Ltd., we understand the importance of innovation and sustainability within the sector. Established in 2010, we specialize in the research, development, and production of wire tube condensers and copper-aluminum fin heat exchangers, which are essential components for refrigerators, freezers, drinking fountains, and display cabinets. Our commitment to quality and performance sets us apart, offering global procurement partners reliable solutions that drive operational excellence. To achieve high efficiency in chillers, consider optimizing your heat exchange processes. Utilizing advanced materials, like our copper-aluminum fin designs, can significantly enhance thermal conductivity, thereby improving energy use. Regular maintenance and retrofitting your existing systems with new technology can also lead to substantial gains. Furthermore, investing in training for your operational staff to understand the intricacies of chillers can result in better performance and lower downtime, ultimately affecting your bottom line positively. As a leader in this field, Ningbo Senjun is dedicated to meeting the diverse needs of our international partners. By prioritizing energy efficiency and embracing the latest technological advancements, we ensure that our products not only meet but exceed industry standards. Collaborate with us to explore tailored solutions that elevate your service offerings and position your company as an industry giant in the chillers market.

Tips & Tricks for High-Efficiency Chillers Industry Giant Service

| Tip | Description | Expected Outcome |

|---|---|---|

| Regular Maintenance | Schedule periodic checks for refrigerant levels, filters, and electrical connections. | Increased efficiency and longevity of the chiller. |

| Upgrade Components | Replace outdated components with high-efficiency alternatives. | Reduction in energy consumption and operational costs. |

| Optimize Controls | Implement advanced control systems to better monitor and adjust chiller performance. | Improved responsiveness to changing loads and conditions. |

| Water Treatment | Ensure proper water treatment to prevent scaling and corrosion. | Enhanced heat transfer efficiency and reduced maintenance issues. |

| Thermal Insulation | Apply insulation to piping and components to minimize heat gain. | Lower energy usage and improved system performance. |

Expert Tips For High-Efficiency Chillers Dominates Your End-to-End Solution

M

Megan Lewis

I’m very happy with my purchase. The product quality is superb, and the after-sales service was incredibly helpful.

10 May 2025

L

Liam Young

Incredible quality and a helpful customer support team! They made sure my experience was smooth and satisfying.

19 June 2025

Z

Zoe Rivera

I love the quality! The support team was really friendly and addressed all my questions effectively.

05 June 2025

O

Olivia White

Very high quality. The support team was quick to assist and very knowledgeable.

26 May 2025

C

Chloe Hill

What a fantastic purchase! The product quality is exceptional, and the customer service was responsive and professional.

26 June 2025

L

Liam Smith

This product exceeded all my expectations! Outstanding quality and very knowledgeable support team.

12 May 2025