Exhaust Valve Series - Top China Factory Manufacturers for Quality Parts

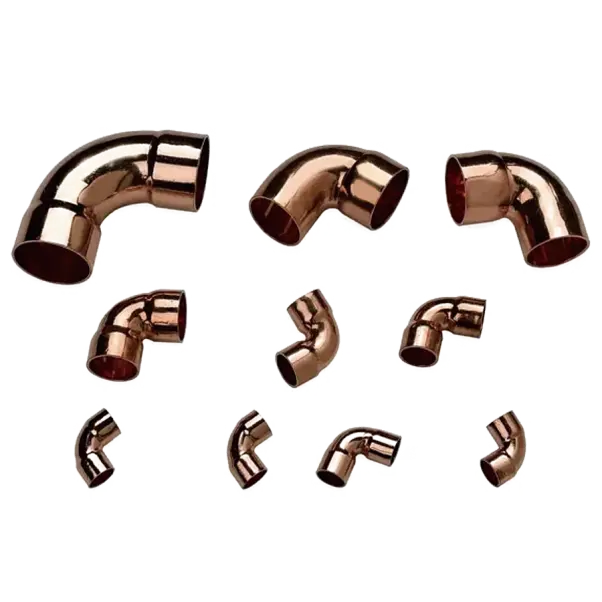

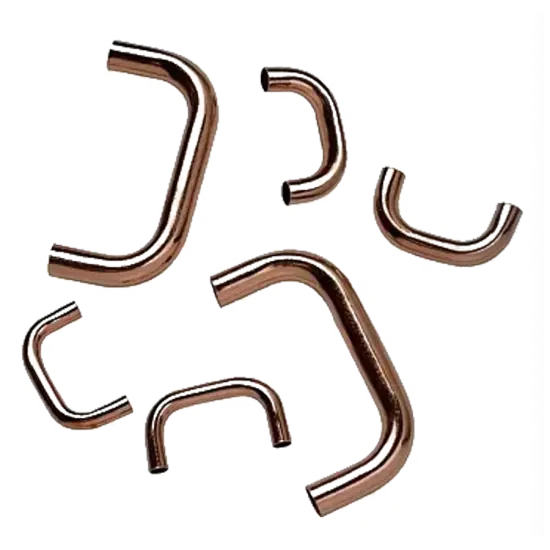

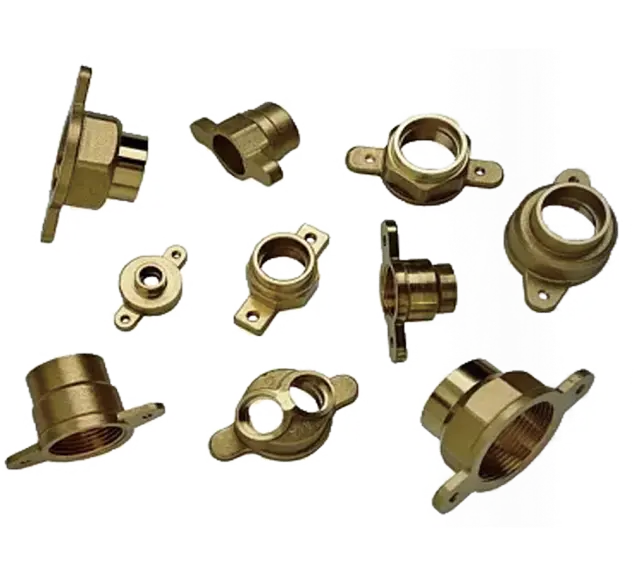

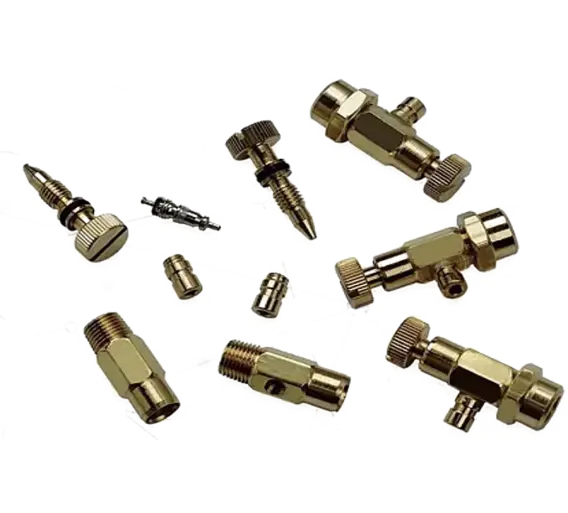

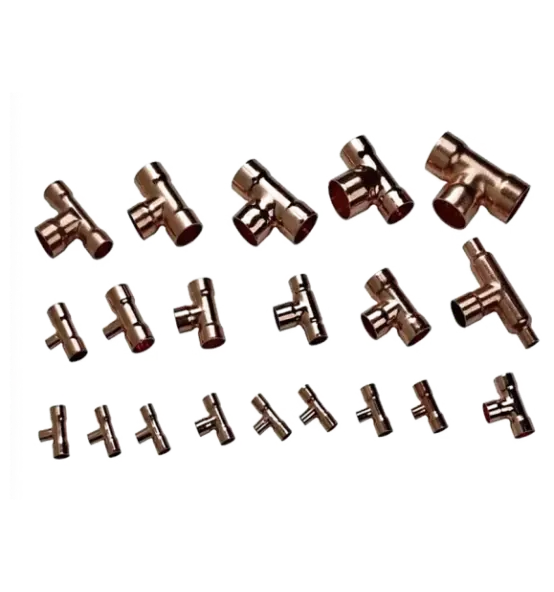

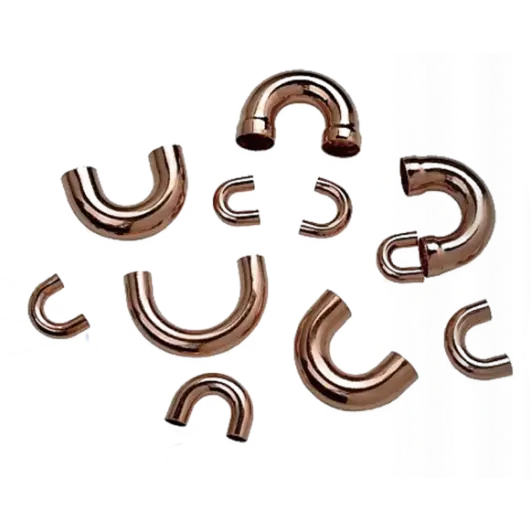

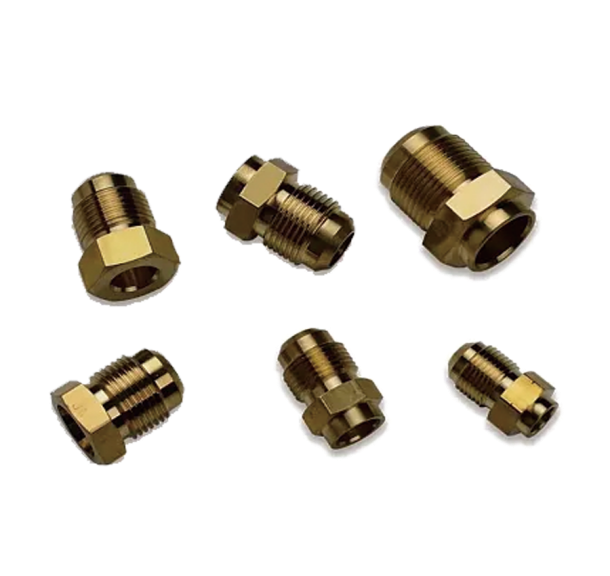

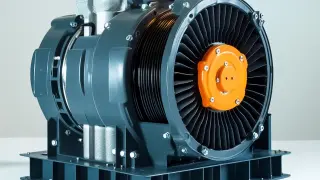

The Exhaust Valve Series from Ningbo Senjun New Materials Co., Ltd. epitomizes precision engineering and durability. These valves are designed to optimize engine performance by ensuring efficient exhaust flow, reducing emissions, and enhancing overall vehicle efficiency. Crafted from high-quality materials, each valve undergoes rigorous testing to guarantee reliability under extreme conditions, Our Exhaust Valves feature advanced designs that cater to various engine specifications, making them suitable for diverse automotive applications. The innovative manufacturing techniques employed ensure that each component is lightweight yet robust, contributing to improved fuel efficiency and engine longevity, Engineered with attention to detail, the Exhaust Valve Series meets international quality standards, offering a seamless fit and easy installation. Trust Ningbo Senjun New Materials Co., Ltd. as your partner in enhancing engine performance and extending the lifecycle of your vehicle. Experience the perfect blend of quality and performance with our Exhaust Valve Series, tailored to exceed the demands of modern automotive technology

Expert Tips For Exhaust Valve Series Manufacturer Sets the Industry Standard

In the ever-evolving landscape of the HVAC and refrigeration industry, the role of exhaust valves cannot be overstated. As manufacturers like Ningbo Senjun New Materials Co., Ltd. pave the way in establishing industry standards, understanding the intricacies of these components becomes crucial for global buyers. Founded in 2010, Senjun has carved a niche in the production of wire tube condensers and copper aluminum fin heat exchangers, serving essential applications in refrigerators, freezers, and display cabinets. One of the standout features of Senjun's exhaust valve series is their innovative design—engineered to enhance efficiency while ensuring durability. By utilizing advanced materials and manufacturing techniques, these valves help optimize the performance of refrigeration systems, resulting in energy savings and increased reliability. Global purchasers looking for high-quality components will find that Senjun's commitment to research and development ensures each product meets rigorous performance standards, backed by industry expertise. Additionally, the company’s strategic focus on customer satisfaction and tailored solutions allows them to cater to a diverse market, adapting to unique client needs across the globe. For procurement professionals, partnering with Senjun not only provides access to top-tier products but also ensures comprehensive support throughout the purchasing process. As the industry continues to advance, collaborating with a leader like Ningbo Senjun will help businesses stay ahead of the curve in terms of quality and innovation.

Expert Tips For Exhaust Valve Series Manufacturer Sets the Industry Standard

| Feature | Description | Benefits | Industry Standard |

|---|---|---|---|

| Material Quality | High-grade alloy steel | Enhanced durability and resistance to wear | ASTM A182 Standard |

| Precision Engineering | CNC machined components | Accurate fit and improved performance | ISO 9001 Certification |

| Heat Treatment | Quenching and tempering processes | Increased strength and fatigue resistance | SAE J429 Grade 5 |

| Sealing Mechanism | Double lip seals | Prevents leakage and extends life | DIN Norm 3760 |

| Testing Procedures | Pressure and thermal cycle testing | Assures reliability under extreme conditions | MIL-STD-810 |

Top 10 Exhaust Valve Series Application Where Innovation Meets 2025

A

Ava Hall

Top-notch quality! The support team is very competent and helped resolve my issues swiftly.

21 May 2025

E

Ethan Nelson

Quality product with a great finish! The support staff were professional and willing to help.

13 June 2025

A

Alexander Murphy

A truly wonderful experience! The quality of this product is exceptional, and the service was fast and friendly.

07 June 2025

H

Henry Martinez

Exceptional product quality! The customer service team went above and beyond to assist me.

27 June 2025

B

Brian James

The craftsmanship is remarkable! The after-sales service was quick and thorough.

28 May 2025

C

Charlotte Mitchell

This product is wonderful! The quality is high, and the customer service team excelled in their support.

17 May 2025