Top China Suppliers & Manufacturers of Conventional Cooling Systems

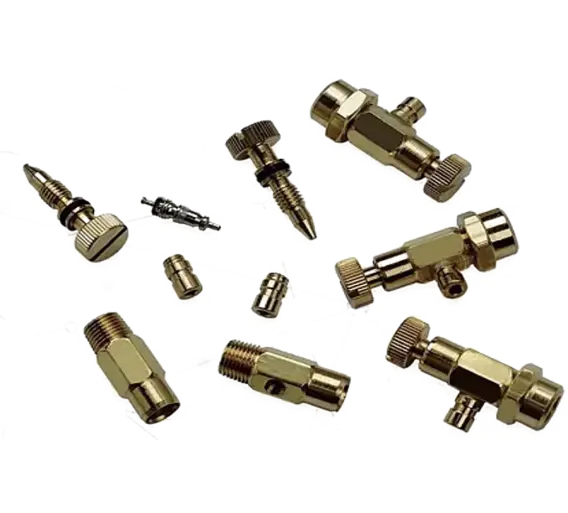

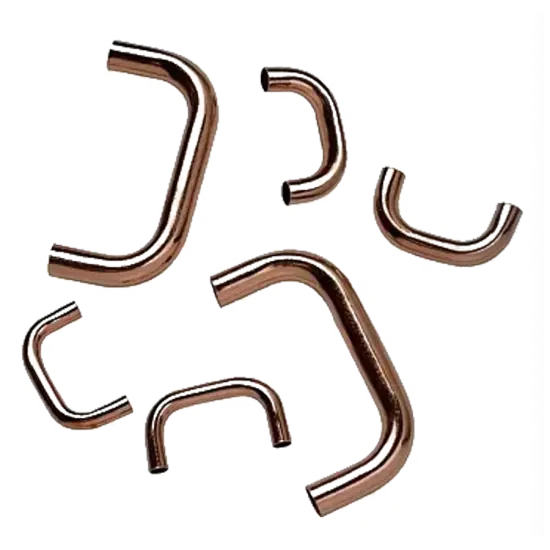

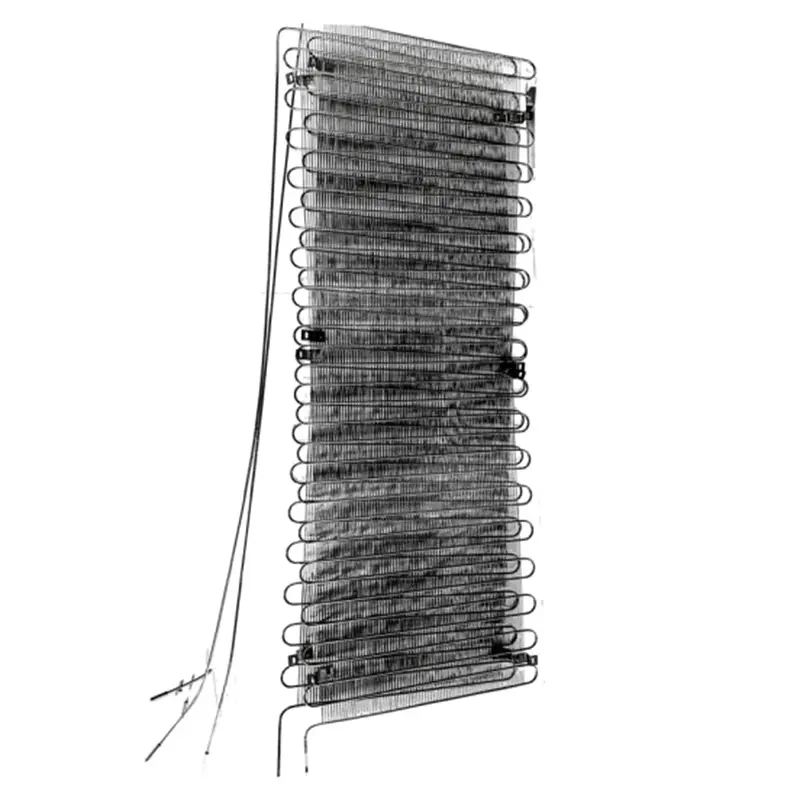

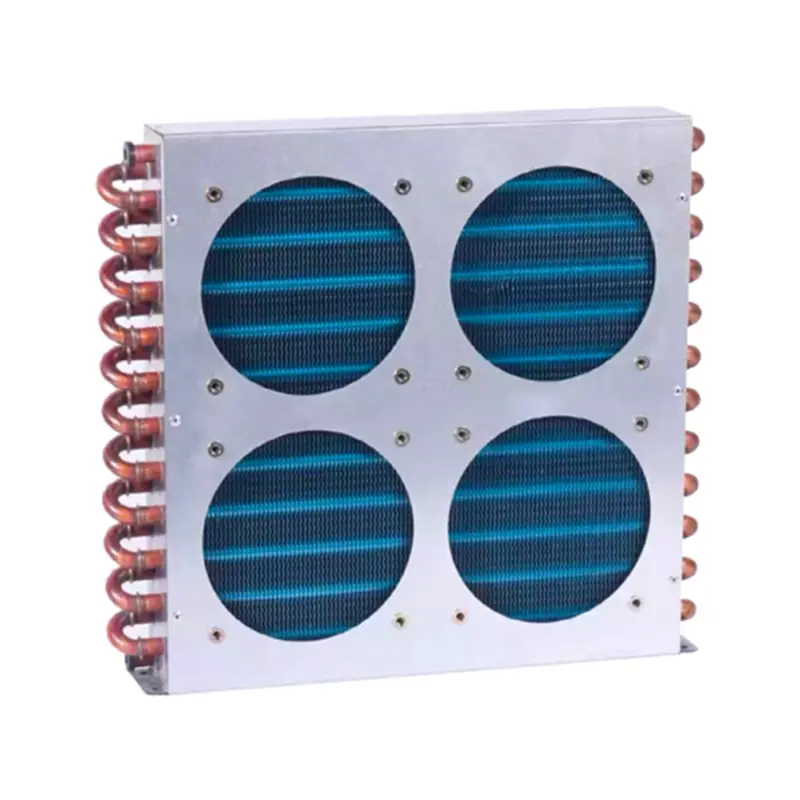

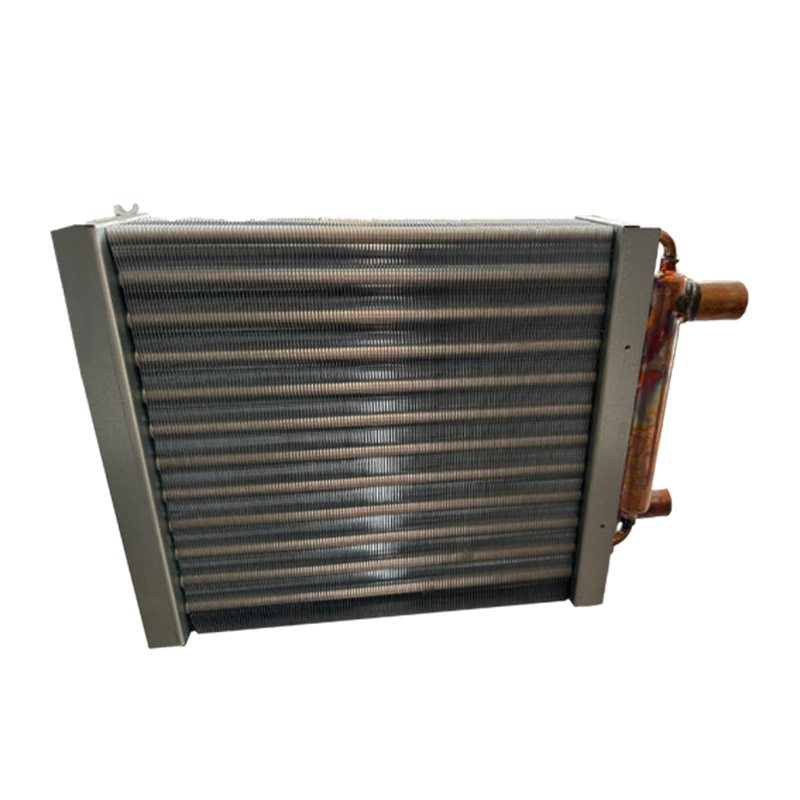

Ningbo Senjun New Materials Co., Ltd. proudly presents its state-of-the-art Conventional Cooling System, designed to meet the demanding needs of various industrial applications. Engineered with precision and efficiency in mind, our cooling solution ensures optimal temperature regulation, enhancing the performance and longevity of critical equipment, This cooling system utilizes advanced technology and high-quality materials to deliver consistent and reliable performance. Ideal for use in manufacturing, HVAC, and other sectors, it is compatible with a wide range of environments, With an emphasis on sustainability, our Conventional Cooling System is designed to minimize energy consumption while maximizing cooling efficiency, resulting in reduced operational costs, Incorporating user-friendly features, the system can be easily integrated into existing setups, making it a versatile choice for businesses aiming to enhance their operational capabilities. Trust Ningbo Senjun New Materials Co., Ltd. for innovative cooling solutions that elevate your processes and drive success

Avoiding Pitfalls Conventional Cooling System Your Trusted OEM Partner Your End-to-End Solution

In today's competitive market, selecting the right cooling system components can make a significant difference in the efficiency and performance of your refrigeration and cooling solutions. As a global purchaser, it's crucial to avoid common pitfalls that can arise from relying solely on conventional cooling systems. At Ningbo Senjun New Materials Co., Ltd., we specialize in crafting high-quality wire tube condensers and copper aluminum fin heat exchangers tailored for a variety of applications, including refrigerators, freezers, drinking fountains, and display cabinets. Partnering with a trusted OEM like Senjun ensures that you receive not just components, but an end-to-end solution designed to meet your specific needs. With over a decade of experience in research and development, our focus on innovation allows us to provide highly efficient and reliable cooling solutions, reducing operational costs and enhancing product longevity. We understand the importance of flexibility and customization to adapt to evolving market demands, which is why our team collaborates closely with clients to deliver top-notch products. Avoiding the pitfalls of conventional cooling systems means prioritizing quality, efficiency, and support. By choosing Ningbo Senjun as your OEM partner, you gain access to superior materials, advanced technology, and expert guidance every step of the way. Together, we can develop cooling solutions that not only meet but exceed industry standards, ensuring your business remains competitive in a rapidly changing landscape.

Avoiding Pitfalls in Conventional Cooling Systems

| Dimension | Description | Potential Pitfall | Solution |

|---|---|---|---|

| Energy Efficiency | Rate of energy use in cooling operations | High operational costs due to inefficiency | Implement energy-saving technologies |

| Maintenance Frequency | How often the system needs maintenance | System breakdowns leading to downtime | Establish a regular maintenance schedule |

| System Compatibility | Integration with existing infrastructure | Installation issues and added costs | Conduct compatibility assessments before purchase |

| Environmental Impact | Effect on local climate and ecology | Regulatory fines and public backlash | Adopt eco-friendly materials and methods |

Quick Tips To Conventional Cooling System Ahead of the Curve For the Current Year

R

Rachel Green

Quality and service are both exceptional! I received prompt assistance from the support team, which made my experience even better.

28 June 2025

M

Megan Lewis

I’m very happy with my purchase. The product quality is superb, and the after-sales service was incredibly helpful.

10 May 2025

R

Ryan Turner

I’m very satisfied! The item quality is great, and the after-sales service was attentive and professional.

23 June 2025

S

Samuel Carter

I can’t get over the quality! The customer service team was incredibly professional and responsive.

17 May 2025

A

Ava Diaz

I can highly recommend this product! The quality is great, and their customer service is professional and helpful.

09 June 2025

L

Liam Carter

Amazing quality! The support team was friendly and responsive to all my inquiries.

23 June 2025