In the ever-evolving landscape of industrial applications, the significance of Copper Capillary Tubes cannot be overstated. These highly efficient conduits are critical in various systems, including refrigeration, air conditioning, and medical devices, where precise fluid control and thermal management are paramount. According to a report by MarketsandMarkets, the global market for capillary tubes is projected to reach $8.2 billion by 2025, underscoring their growing importance across multiple sectors. With applications ranging from HVAC systems to advanced analytical instruments, understanding the functionality and advantages of Copper Capillary Tubes becomes essential for engineers and decision-makers. This guide aims to delve deeply into the characteristics, benefits, and solutions associated with Copper Capillary Tubes, ensuring that readers are well-equipped to harness their potential in industrial settings.

Copper capillary tubes have become an essential component in various industrial applications, particularly in HVACP and plumbing systems. Their primary functionality lies in transferring fluids efficiently, thanks to the capillary action that allows for precision and control in fluid movement. This has led to increased demand, with the North American copper tubes market projected to grow from USD 3.18 billion in 2024 to approximately USD 3.44 billion by 2030, reflecting a strong momentum in industrial reliance on this efficient piping solution.

When selecting copper capillary tubes, consider the type and form that best meets your application needs. The market includes various types such as Type K, Type L, and Type M, each designed for specific pressure and temperature specifications. Additionally, choosing between straight tubes and coils can impact installation and performance.

**Tip:** Always assess the compatibility of copper materials with the fluids being transported to prevent corrosion and ensure longevity.

Investing in high-quality copper capillary tubes can significantly enhance system efficiency and reliability, as evidenced by global market forecasts that predict the copper tube market will reach USD 53.2 billion by 2035, exhibiting a 3.5% CAGR from 2025 to 2035.

**Tip:** Regular maintenance and inspections can help identify issues early and prevent costly disruptions in your industrial processes.

Copper capillary tubes offer numerous key benefits in fluid control applications, making them an indispensable choice in various industrial sectors. One significant advantage is their excellent thermal conductivity, which facilitates efficient heat exchange in refrigeration and air conditioning systems. By maintaining optimal temperatures, these tubes help improve the overall efficiency of fluid transport, thereby reducing energy consumption and operational costs.

Another essential benefit of copper capillary tubes is their corrosion resistance. Unlike other materials that may degrade over time, copper maintains its structural integrity in various chemical environments. This durability ensures a longer lifespan for the equipment and reduces the likelihood of leaks that can lead to costly system failures.

Additionally, their lightweight and flexible nature make installation straightforward, allowing for easier integration into existing systems without the need for intricate modifications. Thus, the utilization of copper capillary tubes greatly enhances the reliability and sustainability of fluid control processes in industrial applications.

Copper capillary tubes are integral in enhancing thermal management in industrial systems, particularly in applications like mini heat pumps and refrigerators. These tubes capitalize on the unique properties of copper, which facilitates superior heat transfer efficiency. The advancement of nanofluids as a medium for heat transfer further optimizes the thermal performance of these capillary tubes, allowing for improved heat and mass transfer in evaporators.

Recent industry forecasts indicate a robust growth in the copper tubes market, driven by the increasing demand for efficient thermal management solutions. With market projections estimating a rise from USD 29.14 billion in 2025 to USD 42.62 billion by 2030, the adoption of copper capillary tubes is expected to play a significant role. Innovative designs, including capillary tube mats equipped with temperature sensors, are advancing the capabilities of thermal control systems, ensuring they meet the diverse needs of modern industrial applications.

| Attribute | Description | Benefits | Common Applications |

|---|---|---|---|

| Material | Copper, a highly conductive metal. | Excellent thermal conductivity enhances heat transfer efficiency. | Refrigeration systems, air conditioning units. |

| Design | Capillary tubes with varying diameters and lengths. | Flexible design allows customization for different systems. | Medical devices, HVAC systems. |

| Functionality | Regulates refrigerant flow in thermal systems. | Improves energy efficiency and system performance. | Cooling systems, heating applications. |

| Durability | Corrosion-resistant properties. | Longer lifespan reduces maintenance costs. | Industrial processes, refrigeration plants. |

Copper capillary tubes have gained significant traction in industrial applications due to their superior thermal conductivity and corrosion resistance compared to alternative materials like aluminum and plastic. Studies indicate that copper allows for more efficient heat transfer, which is crucial in systems such as refrigeration and air conditioning. For instance, copper capillary tubes can enhance the overall performance of cooling systems charged with eco-friendly refrigerants, as seen in research that investigates optimizing charge for R290 refrigerants. This adaptability highlights the versatility of copper as a reliable choice in diverse industrial settings.

Copper capillary tubes have gained significant traction in industrial applications due to their superior thermal conductivity and corrosion resistance compared to alternative materials like aluminum and plastic. Studies indicate that copper allows for more efficient heat transfer, which is crucial in systems such as refrigeration and air conditioning. For instance, copper capillary tubes can enhance the overall performance of cooling systems charged with eco-friendly refrigerants, as seen in research that investigates optimizing charge for R290 refrigerants. This adaptability highlights the versatility of copper as a reliable choice in diverse industrial settings.

Additionally, the comparative advantages of copper extend into the realm of angiogenesis assays, commonly employed in biomedical research to study endothelial cell behavior in simulated environments. In these assays, the structural integrity provided by copper components can significantly influence experimental outcomes. Reports show that copper's antimicrobial properties also play a critical role in maintaining sterile conditions during complex in vitro investigations, further emphasizing why industries favor copper capillary tubes over their alternatives. With ongoing advancements in technology and materials science, the preference for copper as a foundational component in both industrial and research applications appears well-founded.

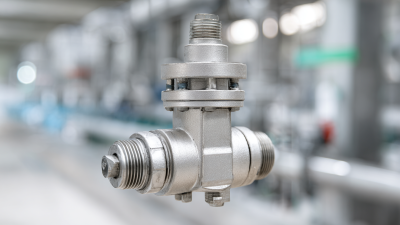

Copper capillary tubes play a vital role in various industrial applications due to their unique properties and versatility. They are often used in HVACR systems, where their excellent thermal conductivity facilitates efficient heat transfer, making them ideal for refrigeration and air conditioning units. In plumbing applications, capillary tubes are essential for connecting different components, ensuring the safe and efficient flow of fluids. Their small diameter and ability to withstand high pressure make them an invaluable asset in reducing the risk of leaks and enhancing overall system performance.

Moreover, the use of copper capillary tubes extends to the medical field, where they are employed in devices for fluid transport and regulation. In the automotive industry, they are found in systems requiring precision fluid management, such as fuel lines and hydraulic systems. The growth of various sectors, including healthcare and automotive manufacturing, has spurred an increased demand for high-quality copper capillary tubes, as they offer reliability and durability across a multitude of applications. As industries evolve and seek more efficient solutions, the importance of copper capillary tubes remains clear, underscoring their significant contributions to modern technology and infrastructure.