In today's competitive HVAC industry, the efficiency of systems heavily relies on the optimal performance of various components, among which the condenser motor plays a critical role. According to a recent market analysis by the HVAC Research Institute, a well-functioning condenser motor can lead to energy savings of up to 30%, underscoring its importance for both operational cost management and environmental sustainability. As temperatures rise globally, the demand for reliable cooling systems intensifies, making it crucial for technicians and homeowners alike to understand and maintain the condenser motor effectively.

Industry expert Dr. Emily Thompson, a leading researcher in HVAC technology, asserts, “The performance of a condenser motor can directly impact not only the cooling efficiency but also the longevity of the entire HVAC system.” This statement emphasizes the need for proactive troubleshooting and replacement strategies to ensure optimal performance. Addressing common issues such as noise, overheating, or mechanical failures can prevent costly repairs in the long run.

By delving into effective techniques for troubleshooting and replacing condenser motors, this article aims to equip readers with the knowledge necessary to maintain their systems efficiently. Understanding these processes not only enhances performance but also contributes to a more energy-conscious approach within the HVAC industry.

The condenser motor plays a vital role in the overall efficiency and functionality of HVAC systems. Positioned within the condenser unit, this motor is responsible for driving the fan that expels heat from the refrigerant to the outside air. By facilitating the heat exchange process, the condenser motor ensures that the indoor environment remains comfortable and that the entire system operates efficiently. A well-functioning condenser motor directly impacts the system's cooling capacity and energy consumption, making its performance critical for HVAC effectiveness.

Understanding how the condenser motor operates can aid in troubleshooting any issues that arise. Symptoms of a failing condenser motor may include unusual noises, reduced airflow, or the system running continuously without reaching the desired temperature. Regular maintenance and inspection can help identify potential problems early on. If the motor is found to be defective, timely replacement is essential for restoring optimal performance to the HVAC system. Knowledge of the motor's role and functionality is essential for homeowners and technicians alike to ensure the longevity and efficiency of heating and cooling systems.

When troubleshooting a condenser motor, recognizing the common signs of failure is critical for maintaining optimal performance. One of the primary indicators of a failing motor is unusual noise. If you hear grinding, buzzing, or a humming sound, it may suggest that the motor bearings are worn out or that the motor is struggling under load. Additionally, a sudden increase in operational noise can indicate that electrical components are damaged or that the motor is overheating, leading to potential failure.

Another significant sign is inconsistent airflow or reduced cooling performance. If the air conditioning system is not adequately cooling the space or if airflow from the vents feels weak, the condenser motor may not be functioning properly. This can lead to not only discomfort but also increased pressure on the system, ultimately reducing its lifespan. Furthermore, check for any visible signs of overheating, such as scorching or burnt wiring, which can signal severe issues within the motor itself. Identifying these symptoms early can save both time and money in repairs while ensuring the efficiency of your cooling system.

| Sign of Failure | Description | Potential Causes | Recommended Action |

|---|---|---|---|

| Overheating | Motor is excessively hot to the touch | Poor airflow, dirty coils, or electrical issues | Check airflow; clean coils; inspect electrical connections |

| Unusual Noises | Grinding or squealing sounds | Worn bearings or loose mountings | Lubricate bearings or replace motor |

| Inconsistent Performance | Motor does not run consistently | Electrical supply issues or motor wear | Check power supply and consider motor replacement |

| Frequent Breakdowns | Motor requires frequent repairs | Aging components or lack of maintenance | Perform regular maintenance or replace motor |

| Tripped Breakers | Circuit breakers trip when motor runs | Short circuit or overload | Inspect wiring and check for short circuits |

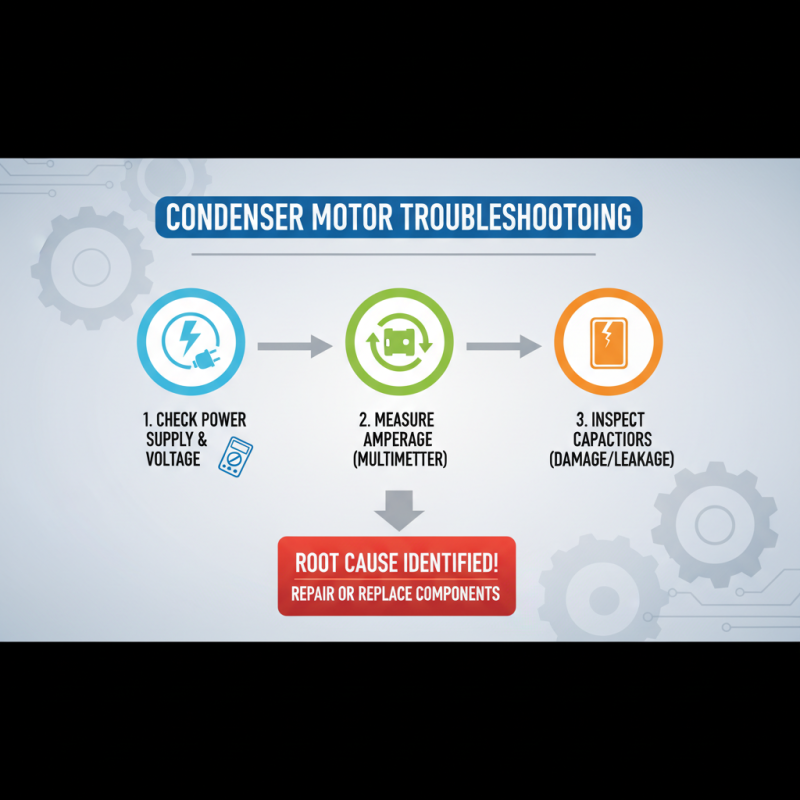

When faced with issues related to a condenser motor, a systematic troubleshooting approach is essential for identifying the root cause of the problem. Begin by checking the power supply to ensure that the motor is receiving adequate voltage. Use a multimeter to measure the electrical current, ensuring it matches the specifications needed for proper operation. If the motor won’t start, inspect the capacitors for any signs of damage or leaking, as faulty capacitors can prevent the motor from running effectively.

Next, examine the motor itself for signs of wear or damage. Listen for unusual sounds, such as grinding or squealing, which may indicate that bearings are worn out or that there is an obstruction in the motor shaft. Additionally, check for overheating, which can signify electrical issues or insufficient ventilation. If necessary, clean any debris around the motor and ensure that the cooling fan is operational. Conducting these checks can help pinpoint whether the motor requires repair or a complete replacement for optimal performance.

When dealing with a defective condenser motor, safety should always be the top priority during removal and replacement. Start by turning off power to the unit at the breaker and ensuring that the environment is safe — check for any hazards, such as water or debris, that could cause accidents. Proper personal protective equipment like gloves and safety glasses is also recommended. According to the U.S. Department of Energy, improper handling of HVAC components can lead to injuries, highlighting the importance of safety protocols when undertaking such repairs.

Once you've ensured safety, the next step is to systematically remove the defective motor. Begin by disconnecting any wiring connections, taking care to label them for easier reconnection later. Removing mounting screws and any associated brackets will allow you to extract the motor from its housing with minimal difficulty. Industry standards suggest documenting each step with photographs or notes, which can aid in avoiding mistakes during reassembly. According to the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), regular maintenance, including the timely replacement of faulty components like condenser motors, can enhance unit efficiency by up to 20%, ultimately promoting optimal performance. After installing the new motor, ensure all connections are secure and that the unit is free from any obstructions before restoring power.

Maintaining the optimal performance of your new condenser motor is crucial for the efficiency and longevity of your HVAC system. To ensure your motor operates smoothly, regular inspections should be part of your maintenance routine. Start by checking for any debris that may obstruct the airflow around the condenser unit. Leaves, dirt, and other obstructions can lead to overheating and increased wear on the motor. Cleaning the area around the unit regularly helps prevent these issues and promotes proper ventilation.

Additionally, monitoring the electrical connections and ensuring that they are secure and free of corrosion is essential. Loose or corroded connections can lead to inconsistent power supply, causing the motor to work harder than necessary. Periodically inspecting the motor’s bearings and lubricating them can also enhance its performance and prevent premature failure. Checking for unusual noises or vibrations during operation will help in identifying potential problems early on, allowing for timely interventions that can prolong the life of your condenser motor. Regular maintenance not only keeps the motor running efficiently but also reduces overall energy consumption, ultimately contributing to cost savings on your energy bills.