Capillary copper applications are rapidly evolving, paving the way for innovative solutions across various industries, including electronics, automotive, and renewable energy. According to the latest market research report by Grand View Research, the global capillary copper market is projected to reach USD 10.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.4%. This growth is driven by the increasing demand for lightweight and efficient materials that can enhance performance while reducing energy consumption. Leading experts in the field, such as Dr. Michael Reynolds, a noted materials scientist, emphasize the significance of these advancements, stating, "Capillary copper technology is not just a trend; it represents a transformative shift in how we approach thermal management and structural integrity in modern engineering."

As we look towards 2025, several innovative applications of capillary copper are set to emerge, revolutionizing the manufacturing landscape. From advanced heat exchangers that optimize thermal efficiency to cutting-edge electronic components that ensure superior conductivity, the versatility of capillary copper is unmatched. Furthermore, the robust properties of this material facilitate improved heat dissipation in high-performance devices, making it essential in today’s competitive market. Stakeholders are encouraged to stay informed about the latest innovations and applications of capillary copper, as they are likely to play a crucial role in shaping the future of multiple industries.

Capillary copper technology has emerged as a pivotal innovation in various industrial applications, primarily due to its exceptional thermal conductivity and mechanical properties. According to a recent market analysis by Grand View Research, the capillary copper market is expected to grow at a CAGR of 6.3% from 2023 to 2030, driven by the rising demand in sectors such as electronics, automotive, and renewable energy. The unique properties of capillary copper, including its ability to efficiently manage heat transfer, make it ideal for high-performance cooling systems used in advanced electronics, notably in the semiconductor industry.

The importance of capillary copper extends beyond mere thermal management. A report from MarketsandMarkets highlights that the integration of capillary copper in manufacturing can enhance energy efficiency by up to 30%, aligning with global sustainability goals. This technology's capability to improve performance in heat exchangers and compact power systems is vital as industries strive for lower emissions and reduced energy consumption. As innovations progress, we anticipate that capillary copper will play an integral role in the development of next-generation technologies, making it essential for stakeholders to stay informed about its applications and advancements.

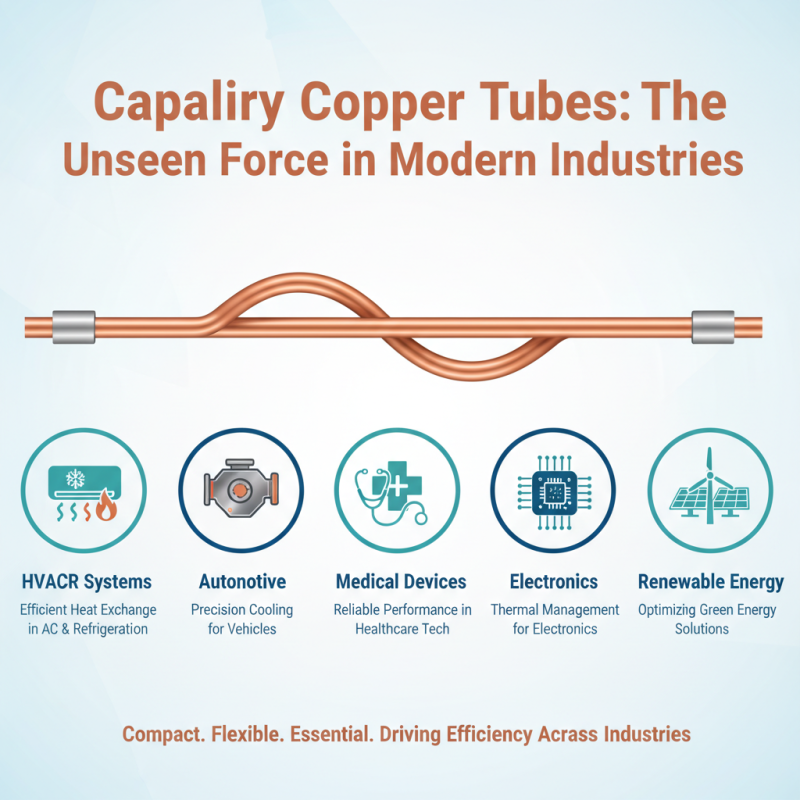

Capillary copper tubes are becoming increasingly vital in various modern industries due to their unique properties and versatility. One of the primary applications is in HVACR systems, where these tubes facilitate efficient heat exchange, contributing to energy savings and improved system performance. Their compact size and flexibility allow for easy integration into complex designs, making them ideal for both residential and commercial heating, ventilation, and air conditioning systems.

In the plumbing sector, capillary copper tubes are favored for their durability and resistance to corrosion. They are often utilized in plumbing installations that require precise fluid control and reliable connectivity. Furthermore, industries such as automotive and refrigeration are leveraging capillary tubes for their effective thermal management solutions. As organizations strive to enhance efficiency and sustainability in various applications, the innovation surrounding capillary copper continues to evolve, reflecting its importance in contemporary manufacturing processes.

Innovative manufacturing techniques in the production of capillary copper products have become pivotal in meeting the evolving demands across various applications. A notable trend is the adaptation of specific types of copper tubes, such as Type K, Type L, and Type M, which are designed to cater to diverse needs in HVACR, plumbing, and electronic applications. The flexibility of capillary tubes makes them a preferred choice for intricate wire bonding applications, particularly in high-density circuits where precision is crucial.

Recent advancements in manufacturing processes are enabling improved interconnectivity in electronic devices, especially for flip-chip packaging. These innovations focus on creating smaller bump structures that facilitate higher interconnect densities, despite the challenges they present, such as increased complexity and costs. Additionally, the CuPRA capillary copper products are designed to handle both high pin count devices as well as standard low pin count applications, reflecting the versatility and demand for reliable performance in the market. As the global copper tube market is projected to grow significantly, the emphasis on innovative manufacturing techniques will be paramount in advancing capillary copper applications across industries.

This chart illustrates the expected market demand for various capillary copper applications in 2025, highlighting significant sectors such as Electronics, Automotive, Telecommunications, Renewable Energy, and Medical Devices.

As we look towards 2025, the capillary copper market is poised for significant growth driven by advancements in technology and increasing demand across various sectors. Recent studies indicate that the HVACR and plumbing applications are expected to dominate the market, with capillary tubes being crucial for efficient fluid transfer and thermal regulation. These tubes, known for their small diameter and high precision, are becoming increasingly critical as industries strive for enhanced efficiency and sustainability.

Projections suggest that the global copper tubes market will expand at a compound annual growth rate (CAGR) of over 5% from 2023 to 2028, with Type L and Type K pipes likely to see substantial growth due to their favorable properties in residential and commercial applications. Additionally, innovations in the manufacturing process, such as the development of advanced techniques for producing seamless and flexible capillary tubes, are driving further adoption. As industries adopt green technologies, the demand for high-performance capillary copper tubes is set to rise, reshaping the landscape of its applications and leading to innovative solutions in energy-efficient systems.

Capillary copper applications are on the rise, driven by their unique properties that allow for efficient thermal management and fluid dynamics. However, the implementation of such technologies presents several challenges. One major issue is the difficulty in achieving uniformity in capillary structures during manufacturing. Variations can significantly impact performance, leading to inefficiencies. To address this, advanced manufacturing techniques, such as additive manufacturing and precision casting, are being explored to create more consistent capillary networks that enhance performance.

Another challenge lies in the compatibility of capillary copper with different fluids in various applications. Corrosion and wear over time can degrade performance and reliability. Solutions include the development of specialized coatings and treatment methods that enhance the corrosion resistance of copper. Additionally, continuous research into alternative fluid compositions can help minimize compatibility issues, ensuring long-lasting and efficient operation in various environments.

By focusing on these challenges and their corresponding solutions, the path towards widespread adoption of capillary copper technologies becomes clearer, paving the way for innovative applications in the near future.