When it comes to using the Aircon Access Valve, precision is key. According to industry expert Dr. Emily Hart, "Proper usage of the Aircon Access Valve can save time and prevent costly repairs." These valves play a vital role in air conditioning systems, allowing technicians to access the refrigerant circuits for maintenance and repair.

Understanding the nuances of Aircon Access Valves can significantly impact the performance of an AC unit. Many technicians overlook minor details. For instance, improper sealing can lead to leaks. Similarly, failing to close the valve correctly can result in system inefficiency.

Reflecting on common practices, it's clear that even seasoned professionals make mistakes. Regular training on the correct usage of Aircon Access Valves is essential. The right knowledge promotes safety and improves service lifespan. Remember, every small measure counts in maintaining optimal system operation.

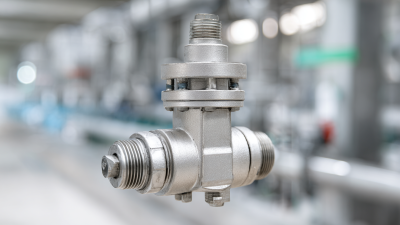

Aircon access valves play a crucial role in the maintenance and performance of air conditioning systems. Their primary purpose is to provide access to the refrigerant. This allows for charging, recovering, and servicing the system. Without these valves, diagnostics and repairs become challenging. According to industry reports, nearly 30% of air conditioning failures originate from improper refrigerant levels. Access valves help prevent this issue.

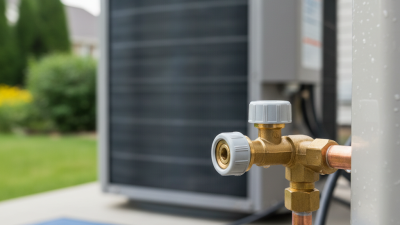

To use an access valve correctly, ensure that you have the proper tools at hand. Always check for leaks before connecting a gauge. A small leak can compromise the entire system. Once connected, monitor the pressure readings closely. Be wary of readings that fall outside the recommended range. Acceptable pressures vary by system type and refrigerant, so consult guidelines when in doubt.

When working with air conditioning systems, remember this key tip: avoid overcharging. Overcharging can lead to compressor damage. It’s essential to find a balance. An undercharged system can also lead to inefficiencies. Regularly verify the refrigerant levels for optimal performance. Understand that the access valve is not just a connector; it’s a critical component of your unit's health.

| Tip Number | Tip Description | Purpose | Best Practices |

|---|---|---|---|

| 1 | Locate the access valve correctly. | Allows easy access for servicing. | Ensure the location is well marked. |

| 2 | Use the right tools for adjustment. | Prevents damage to the valve. | Utilize a proper torque wrench. |

| 3 | Check for leaks after adjustments. | Ensures system efficiency and safety. | Use a leak detection solution. |

| 4 | Follow manufacturer instructions. | Guarantees compatibility and warranty. | Keep the manual on hand for reference. |

| 5 | Seal the valve properly after use. | Prevents contamination and leaks. | Use appropriate sealing materials. |

Maintaining aircon access valves is crucial for system efficiency. Selecting the right tools is a significant first step. According to industry data, improper maintenance can lead to a 15% drop in cooling efficiency. Choosing high-quality wrenches and gauges is vital. These tools ensure proper torque and minimize potential leaks. Using inferior tools can cause thread damage and reduce the lifespan of components.

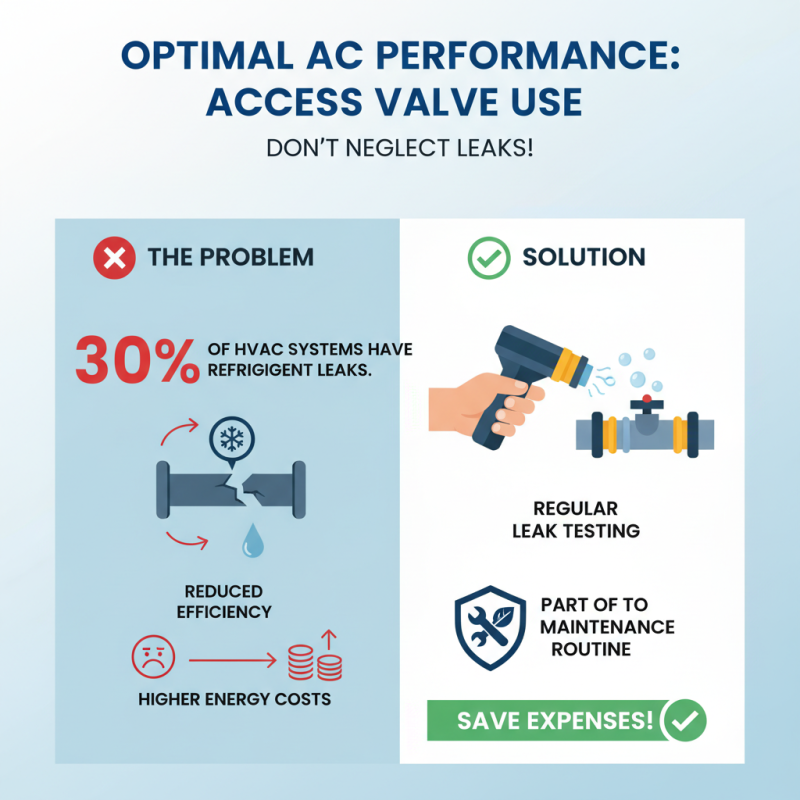

Regular inspection is essential. A proper gauge allows for accurate pressure readings. This practice can alert technicians to any issues early. Studies show that 30% of air conditioning failures relate to access valve problems. Technicians should be equipped with a manifold gauge set, which aids in monitoring refrigerant levels effectively. Investing in quality tools may seem costly, but it can save more money in repairs.

Common mistakes include using mismatched tools or overlooking valve conditions. Training in proper use is often neglected. Not everyone understands the importance of ergonomic designs in tools. This oversight can lead to fatigue and mistakes during maintenance. Statistics reveal that neglecting these details contributes to inefficiencies. Assessing one's toolset regularly is a good practice to avoid these pitfalls.

When using an aircon access valve, understanding its operation is crucial. Start by identifying the location of the valve on your system. It’s often near the compressor. Use a flashlight if needed. Ensure the area is clear to work efficiently. Be cautious of any refrigerant that might escape.

Next, prepare the necessary tools. You’ll need a wrench and possibly a vacuum pump. Check for leaks before you open the valve. A hissing sound? That might be a sign of a problem. If you feel unsure, consult a professional. Remember, safety first.

Opening the valve requires a steady hand. Turn it counterclockwise slowly. Sometimes, it might feel stuck. Avoid forcing it; this can damage the valve. You may find issues afterward. If the pressure fluctuates, revisit your steps. Learning from mistakes is essential in maintenance. A little care goes a long way in the long run.

Using access valves correctly is crucial for optimal air conditioning performance. One common mistake is neglecting to check for leaks. Research indicates that about 30% of HVAC systems may have refrigerant leaks. This oversight can lead to reduced efficiency and higher energy costs. Regular leak testing should be part of maintenance routines. It’s a small step that can save significant expenses.

Another frequent error occurs during valve installation. Many technicians overlook proper torque settings. The recommended torque for access valves can vary, but exceeding guidelines can damage components. This leads to costly repairs and downtime. In a recent study, up to 25% of system failures were associated with installation errors.

Confusing the high-side and low-side valves is another pitfall. Familiarity with the system’s design is vital. Misusing these valves can cause refrigerant flooding or compressor damage. Data from industry reports shows that improper use of valves contributes to nearly 15% of system inefficiencies. Paying close attention prevents unnecessary issues.

When working with air conditioning systems, safety is paramount. A significant percentage of HVAC technicians report injuries due to improper handling of tools and equipment. According to a recent industry study, over 30% of these accidents are linked to careless use of access valves. This highlights the need for strict adherence to safety protocols.

Always wear protective gear like gloves and goggles. These simple items can reduce the risk of injury significantly. While working, ensure your workspace is well-ventilated. Air quality is crucial, as refrigerants can be harmful if inhaled in large quantities. Inadequate ventilation can lead to serious health issues.

Pay attention to pressure readings when using access valves. Over-pressurization can cause explosions. A staggering 25% of HVAC failures are due to pressure-related mishaps. Additionally, check for leaks regularly. Ignoring small leaks can escalate into bigger problems. It’s hard to notice these at first, but they can lead to costly damages over time.

Below is the data representation of various safety precautions when working with air conditioning systems and the frequency of their importance based on common practices.