In the evolving landscape of global procurement, selecting the appropriate fan motor is crucial for enhancing operational efficiency and meeting sustainability goals. According to a recent report by MarketsandMarkets, the global fan motor market is projected to reach $XX billion by 2025, driven by increasing demand in HVAC systems and energy-efficient applications. As industries prioritize performance and accountability, understanding the specifications, types, and applications of fan motors becomes imperative.

This guide aims to provide a comprehensive checklist for procurement professionals to navigate through the complexities of fan motor selection, ensuring they make informed decisions that align with their organization's operational needs and environmental standards. By delving into critical factors such as energy efficiency, compatibility, and lifecycle cost, this resource will help streamline the procurement process for fan motors across various sectors.

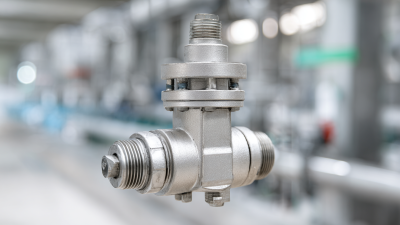

When selecting a fan motor for your global procurement needs, understanding the specifications is crucial. Factors such as power efficiency, noise levels, and motor types play an essential role in making the right choice. For instance, consider the energy consumption of different motor types. Brushless motors, while often more expensive upfront, can offer superior efficiency and longevity, ultimately saving costs in operational expenses.

Tips: Always examine the warranty and support offered with the motor. A robust warranty indicates manufacturer confidence in their product and can safeguard your investment. Additionally, factor in the intended environment of the fan motor—whether it’s for residential or industrial use can significantly impact the specifications you’ll need to prioritize.

Another key aspect to consider is the installation requirements. Some fan motors may demand specialized setups or additional components. Make sure to review installation guides and consult experts if necessary, as proper installation can influence the performance and lifespan of the fan motor. Adopting a methodical approach in evaluating these specifications will lead to a smarter procurement decision that aligns with your operational goals.

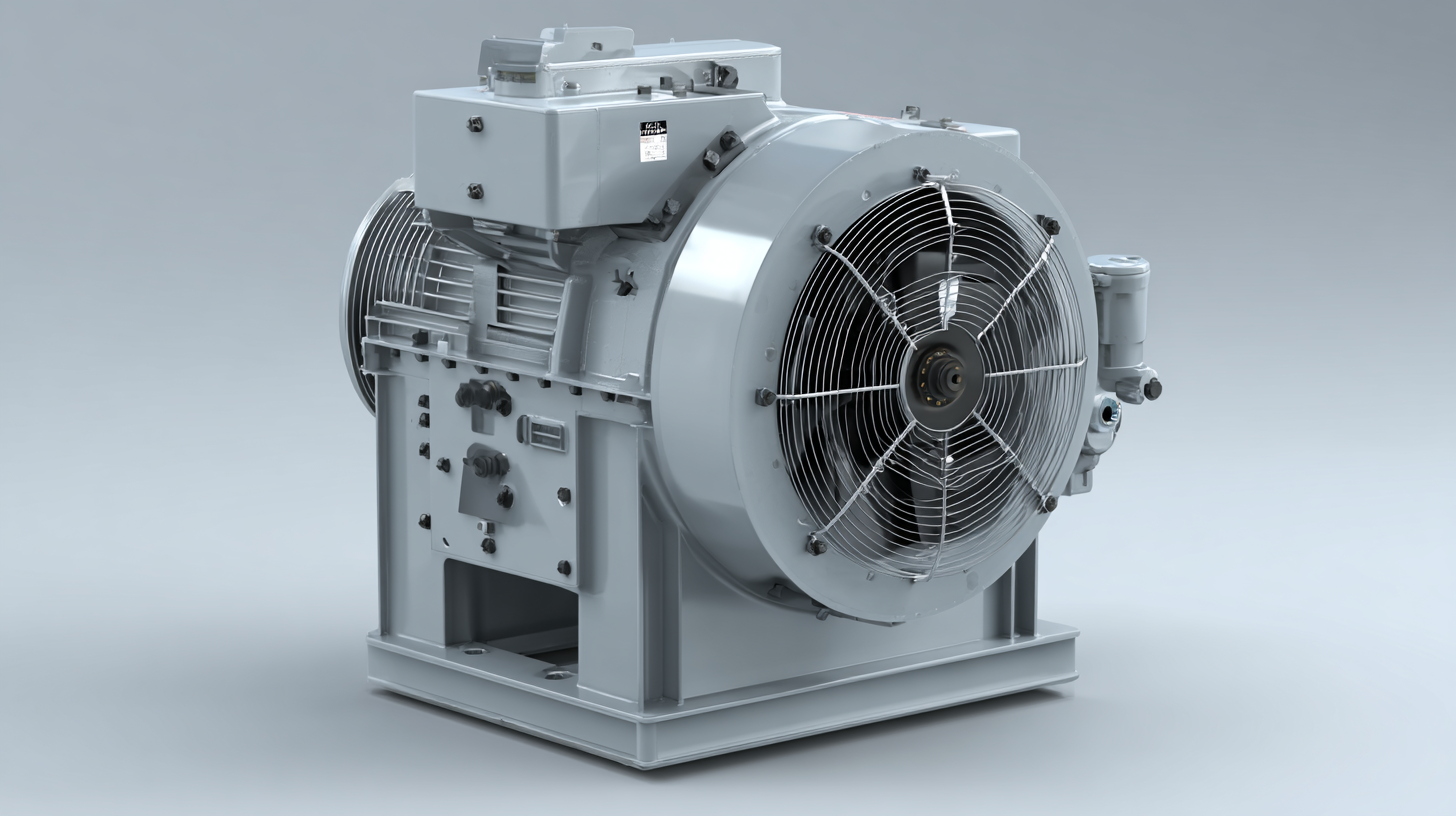

When it comes to selecting energy-efficient fan motors, understanding efficiency ratings is crucial for global procurement needs. The global market categorizes energy-efficient motors into various levels, including IE1 to IE5, reflecting improvements in energy consumption. According to recent findings, motors classified as IE3 and IE4 demonstrate significant energy savings, often exceeding 10% compared to standard IE1 motors. This substantial difference not only contributes to reduced operational costs but also plays a vital role in sustainability efforts across industries.

Furthermore, the report detailing energy-efficient motor-driven systems highlights that businesses embracing the Motor Challenge Programme can achieve marked improvements in energy efficiency. These programs encourage the adoption of technologies that enhance performance while simultaneously lowering energy consumption. In a comparative study between buildings in Brazil, the U.S., and Portugal, regulations are evolving to maximize energy savings, indicating a growing global trend towards leveraging advanced energy efficiency labeling. This not only helps businesses comply with international standards but also promotes a culture of responsible energy use.

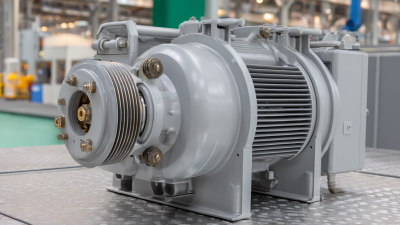

When it comes to selecting the right fan motor for your global procurement needs, understanding the difference between AC and DC motors is essential. AC motors, often preferred for their durability and high performance, are typically used in applications requiring continuous operation, such as industrial fans and HVAC systems. According to a report by the International Energy Agency, AC motors account for about 65% of the energy consumption in the global industrial sector, emphasizing their significance in large-scale applications.

On the other hand, DC motors are gaining traction due to their energy efficiency and precise speed control, making them ideal for applications like portable fans and electronic devices. A recent market report highlighted that DC motors could improve energy savings by 20-30% compared to traditional AC motors, making them an appealing choice for energy-conscious procurement strategies.

**Tips:** When considering fan motors, evaluate the total cost of ownership, which includes initial costs, energy efficiency, and maintenance requirements. Additionally, consult manufacturers for data sheets that provide performance metrics tailored to your industry, ensuring alignment with your operational needs. Lastly, factor in the environmental implications; many companies are now prioritizing sustainability in their procurement processes, with DC motors often representing a greener option.

| Motor Type | Key Features | Applications | Efficiency | Cost |

|---|---|---|---|---|

| AC Motor | Robust, simple design, requires less maintenance | Industrial fans, HVAC systems, exhaust fans | Less efficient at low speeds | Lower initial cost |

| DC Motor | High efficiency, variable speed control, quieter operation | Computer cooling fans, automotive applications, small appliances | More efficient, especially at lower speeds | Higher initial cost |

| EC Motor | Combines benefits of AC and DC, more compact, programmable | HVAC, refrigeration systems, variable air volume systems | Very high efficiency | Higher cost but cost-saving over time due to efficiency |

When selecting a fan motor that meets global procurement needs, assessing reliability and lifespan is paramount. Industry standards offer invaluable insights into the durability and efficiency of fan motors, ensuring that procurement decisions are based on credible data. For instance, compliance with standards such as IEC and NEMA can provide assurances regarding performance across various operating conditions. Motors that meet these benchmarks often exhibit longer lifespans, reducing the need for frequent replacements and minimizing operational disruptions.

Additionally, the evaluation of a motor's ratings for thermal performance and energy efficiency is crucial. Motors designed with better thermal management can operate efficiently over extended periods without overheating, thus prolonging their operational lifespan. Industry standards not only guide the design parameters but also provide specifications that help in assessing the suitability of motors for specific applications. By focusing on these metrics during the procurement process, organizations can enhance reliability, optimize efficiency, and ultimately achieve greater satisfaction with their chosen fan motor solutions.

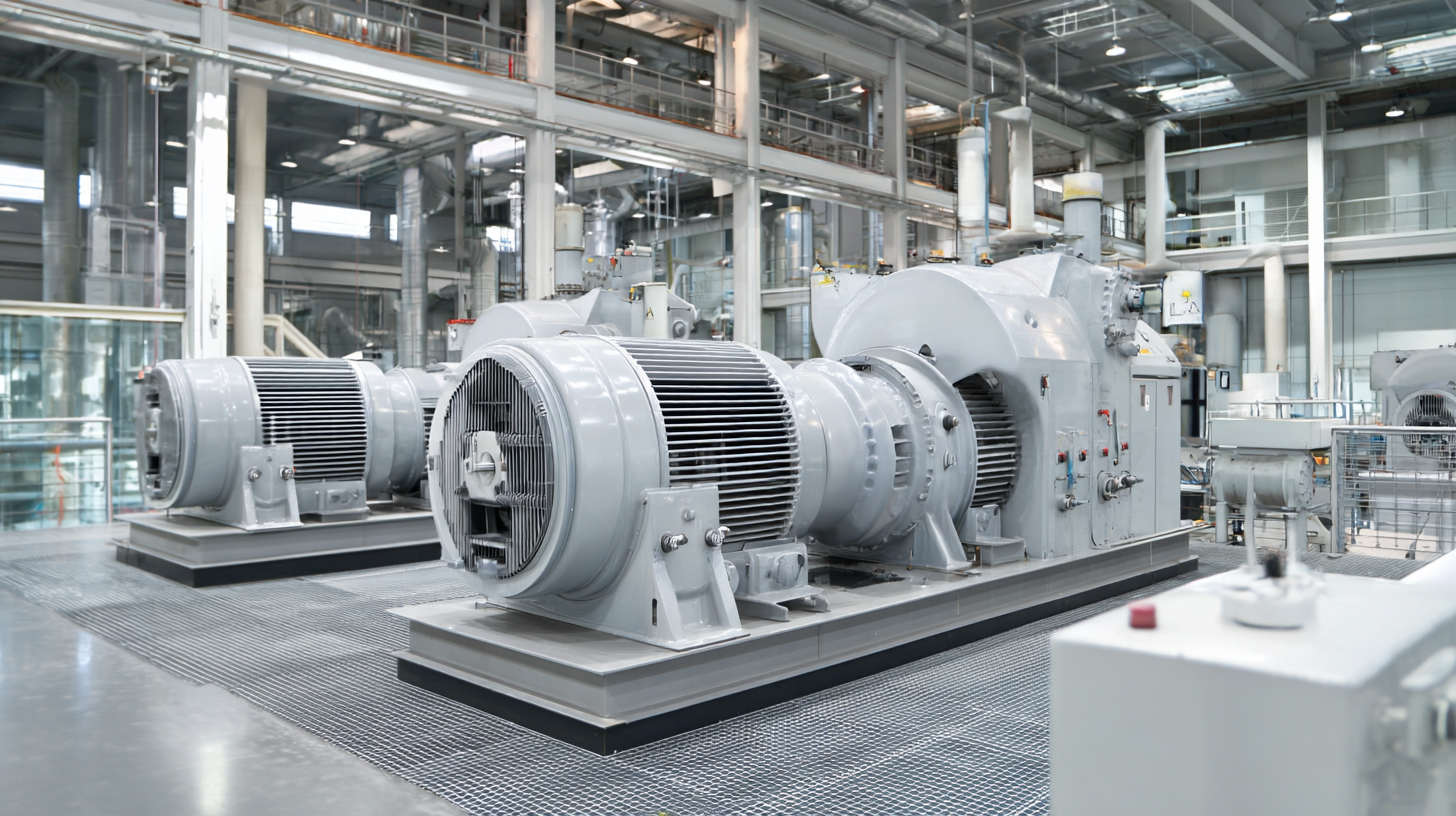

Navigating global supply chains for sourcing fan motors can be a complex endeavor, but understanding key trends and market data can streamline the process. According to a recent industry report by MarketsandMarkets, the global fan motor market is projected to grow from $12.1 billion in 2021 to $16.7 billion by 2026, highlighting a CAGR of 6.5%. This growth is predominantly driven by increased demand in HVAC systems and industrial applications, underscoring the importance of strategic procurement decisions in this sector.

When sourcing fan motors internationally, it's essential to consider the supply chain's geographical dynamics. A study by McKinsey & Company emphasizes the rise of Asia-Pacific as a manufacturing hub, accounting for over 45% of global production. Companies should tap into this trend by establishing partnerships with reliable manufacturers in these regions. Additionally, integrating digital tools for real-time tracking and analytics can significantly enhance supply chain transparency and efficiency, allowing for better negotiation and sourcing of high-quality fan motors at competitive prices. By aligning sourcing strategies with market insights, organizations can secure their supply chains effectively while meeting their operational needs.