In the world of HVAC installations, choosing the right components is crucial for ensuring system efficiency and longevity. HVAC copper press fittings have gained significant attention due to their reliable performance and ease of installation. According to a recent industry report by MarketsandMarkets, the global HVAC market is projected to reach $250 billion by 2026, with a growing preference for advanced and sustainable solutions, including copper press fittings. These fittings not only provide a secure and leak-free connection, but they also enhance the overall durability of HVAC systems. As professionals look to optimize their projects, understanding how to select the best HVAC copper press fittings becomes essential in maintaining high standards and achieving lasting results in HVAC applications.

When selecting HVAC copper press fittings for your next project, it's essential to consider a variety of factors to ensure optimal performance and reliability. One critical aspect is the type of application—whether it is for residential, commercial, or industrial purposes. Each setting may require different specifications regarding pressure ratings and temperature ranges. Additionally, look into the compatibility of the fittings with existing system components to prevent leaks and ensure seamless integration.

Another significant factor is the installation method. With the recent emphasis on flame-free solutions in the cooling sector, many professionals are now turning to press-fit technology, which offers quick and efficient connections without the risks associated with soldering. This method not only enhances safety but also reduces installation time, making it a viable choice for modern HVAC projects. Furthermore, assess the quality and durability of the fittings, ensuring they meet industry standards to withstand the rigors of your specific application and environment. By considering these elements, you can make a more informed decision that aligns with your project needs.

When selecting HVAC copper press fittings for your next project, compatibility with existing systems should be a top priority. Proper fitting ensures seamless integration, which is essential in maintaining the efficiency and reliability of the overall HVAC system. Just as renewable energy sources have transformed traditional power systems, necessitating thoughtful integration with low-inertia grids, so too must HVAC components align perfectly with pre-existing infrastructure to avoid costly modifications and downtime.

Consideration of compatibility also extends to how new components interact with smart home technologies. Recently, the introduction of open-source protocols to unify device communication underscores the importance of ensuring that new systems work harmoniously with established technologies. Just like the need for hybrid inverters to coordinate under mixed generation scenarios, HVAC fittings must also harmonize with existing piping and hardware to create a dependable solution that endures under various operational conditions.

This attention to compatibility can greatly enhance system performance and longevity while reducing potential maintenance challenges in the future.

When it comes to selecting the best HVAC copper press fittings for your next project, understanding the various types available is crucial. Copper press fittings are widely used due to their durability and reliability, making them suitable for both residential and commercial applications. The main types of copper press fittings include standard press fittings, reducing fittings, and specialty fittings, each serving specific functions in piping systems.

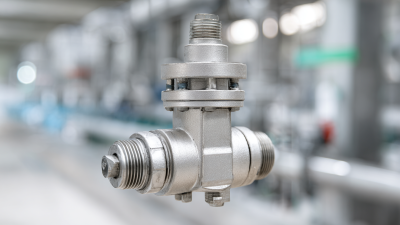

Standard press fittings are designed for straightforward connections and are the most commonly used type. They provide a secure seal, reducing the risk of leaks. Reducing fittings, on the other hand, allow for different pipe sizes to be connected, making them essential for transitions within a system. Specialty fittings, which include items like elbows and tees, help navigate complex piping configurations. When selecting fittings for your HVAC project, consider factors such as compatibility with pipe sizes, ease of installation, and the specific requirements of your plumbing layout. Understanding these different types will help streamline your project and ensure a successful installation.

When it comes to installing HVAC systems, using copper press fittings can significantly streamline the process. To ensure a successful installation, it's essential to prepare your materials thoroughly. Start by selecting high-quality copper pipes and compatible press fittings that meet industry standards. Properly clean and deburr the pipe ends to remove any sharp edges or debris that could interfere with a secure seal. This preparation not only enhances the connection but also prolongs the lifespan of the system by preventing leaks.

During the installation process, using the right tools is crucial. Invest in a reliable press tool that can achieve the necessary pressure for a secure fitting. It's recommended to work in a well-lit area to maintain visibility and ensure precision. As you press each fitting onto the pipe, apply consistent pressure and double-check alignment before engaging the tool. Additionally, remember to inspect each connection afterward; a quick visual check can save time and resources by catching potential issues before they escalate. By following these tips, you can effectively utilize copper press fittings, maintaining efficiency and reliability in your HVAC projects.

When selecting HVAC copper press fittings for your next project, it's essential to prioritize maintenance and longevity to ensure optimal performance. Copper fittings are known for their durability and resistance to corrosion, but their performance over time can significantly depend on proper maintenance practices.

Regular inspections and cleaning can help identify any signs of wear and tear before they result in costly repairs.

To maintain the longevity of your HVAC system, consider incorporating these tips: