In the complex world of HVAC systems, the role of key components often goes unrecognized, yet they are crucial for optimal performance and efficiency.

One such component is the Refrigeration Filter Drier, which serves both as a filter and a drying agent, ensuring the reliable operation of cooling systems. According to a report by the U.S. Department of Energy, improper maintenance and inadequate filtering can lead to system failures and increased energy consumption, which can be as high as 30% in poorly maintained systems. Furthermore, the Refrigeration Filter Drier plays a vital role in preventing contaminants from damaging compressors, prolonging the lifespan of HVAC equipment. By understanding the importance of this essential component, HVAC professionals can enhance system reliability and improve overall efficiency, ultimately contributing to energy savings and reduced environmental impact in our modern climate-controlled environments.

One such component is the Refrigeration Filter Drier, which serves both as a filter and a drying agent, ensuring the reliable operation of cooling systems. According to a report by the U.S. Department of Energy, improper maintenance and inadequate filtering can lead to system failures and increased energy consumption, which can be as high as 30% in poorly maintained systems. Furthermore, the Refrigeration Filter Drier plays a vital role in preventing contaminants from damaging compressors, prolonging the lifespan of HVAC equipment. By understanding the importance of this essential component, HVAC professionals can enhance system reliability and improve overall efficiency, ultimately contributing to energy savings and reduced environmental impact in our modern climate-controlled environments.

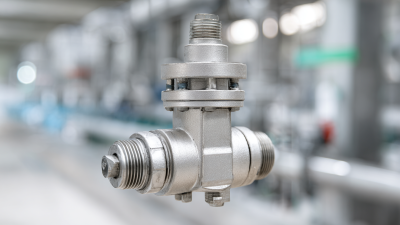

In HVAC systems, the efficiency and reliability of refrigeration cycles greatly depend on the components involved, particularly the refrigeration filter drier. This crucial device serves multiple roles, primarily filtering out contaminants and absorbing moisture from the refrigerant. By trapping unwanted particles, such as dirt and debris, the filter drier prevents these impurities from circulating through the system, thereby protecting vital components like compressors and evaporators from wear and tear.

Moreover, moisture in the refrigeration system can lead to serious issues such as corrosion, freezing, and overall pressure imbalance. The filter drier mitigates these risks by using desiccants that absorb excess moisture, ensuring a clean and stable refrigerant flow. This optimal fluid path enhances energy efficiency, as a well-maintained system operates smoothly and requires less energy to maintain desired temperature levels. Consequently, investing in a high-quality refrigeration filter drier is not only essential for operational reliability but also significantly contributes to the overall efficiency of HVAC systems, ultimately resulting in cost savings and extended equipment lifespan.

Refrigeration filter driers play a critical role in HVAC systems by removing moisture and contaminants from the refrigerant, ensuring efficient and safe operation. There are several types of refrigeration filter driers, each designed for specific applications. One common type is the liquid line filter drier, which primarily focuses on eliminating moisture and acid from the refrigerant in the liquid line of the system. This type is essential for all air conditioning and refrigeration systems, as it protects the compressor from damage caused by contaminants.

Another type is the suction line filter drier, which is typically installed on the suction line coming from the evaporator. This filter drier captures any debris that may circulate back to the compressor, thus preventing potential failure. Additionally, there are specialized filter driers designed for low-temperature applications, featuring unique materials that can effectively handle the specific demands of such environments. Understanding these different types and their applications is crucial for HVAC professionals to ensure optimal system performance and longevity.

| Type of Refrigeration Filter Drier | Description | Applications | Key Features |

|---|---|---|---|

| Liquid Line Filter Drier | Removes moisture and contaminants from the refrigerant. | Used in residential and commercial refrigeration systems. | High moisture absorption capacity, robust construction. |

| Suction Line Filter Drier | Installed in the suction line to protect the compressor. | Commonly used in air conditioning systems to ensure compressor longevity. | Ability to filter larger particles, can handle thick fluids. |

| Bi-directional Filter Drier | Can be used in both directions in the refrigeration system. | Ideal for systems with reversing cycles, like heat pumps. | Versatile use, space-efficient design. |

| Azole Filter Drier | Specialized for use with certain types of refrigerants. | Used in advanced HVAC applications using HFC and HCFC refrigerants. | Chemical compatibility, enhanced filtration capabilities. |

Refrigeration filter driers play a crucial role in enhancing the longevity of HVAC systems by ensuring the effective removal of moisture and contaminants from refrigerants. When moisture enters the refrigerant line, it can lead to corrosion, reduced efficiency, and eventual system failure. By incorporating a filter drier, HVAC systems can maintain optimal performance and extend their lifespan, ultimately saving homeowners from costly repairs and replacements.

To ensure the effectiveness of refrigeration filter driers, it’s essential to perform regular maintenance. One key tip is to check and replace the filter drier as recommended by the manufacturer, usually during routine HVAC service visits. Additionally, contractors should prioritize proper nitrogen purging during system installation and maintenance. This process helps eliminate moisture before charging the system, which significantly reduces the likelihood of future issues related to contaminants.

Another tip for enhancing system longevity is to regularly inspect refrigerant recovery machines, as they are critical in maintaining refrigerant quality. Keeping them well-maintained not only ensures efficient operation but also supports overall HVAC system performance. By taking these proactive measures, HVAC professionals can promote reliable operations and satisfy customer expectations.

A refrigeration filter drier plays a crucial role in maintaining the efficiency and longevity of your HVAC system. Over time, contaminants like moisture, dirt, and debris can accumulate in your system, impairing its performance. Signs that your HVAC system may require a filter drier replacement include inconsistent cooling, increased energy bills, and odd noises from the compressor. According to the Air Conditioning Contractors of America (ACCA), neglecting filter drier issues can lead to system failure, resulting in costs of up to 30% in energy consumption.

To ensure optimum performance, it’s essential to keep an eye on refrigerant pressures. If you notice fluctuating pressures, this could indicate a clogged filter drier or one that has reached the end of its lifespan. Regular maintenance checks can help catch these issues early. The National Institute of Standards and Technology (NIST) suggests that routine filter drier replacement every three to five years can enhance system reliability and efficiency.

Tips for extending the life of your filter drier include monitoring refrigerant levels and ensuring proper airflow throughout the HVAC system. Additionally, investing in a high-quality filter drier can make a significant difference; look for units that meet the AHRI standards for maximum performance and reliability to prevent further complications down the line. Regular inspections and timely replacements can save you money and extend the overall life of your HVAC system.

Refrigeration filter driers play a crucial role in maintaining the efficiency and longevity of HVAC systems. These components are essential for filtering out moisture, debris, and contaminants from the refrigerant, which can otherwise lead to corrosion and damage to the system. Proper maintenance of filter driers is vital to ensure optimal performance.

To maintain refrigeration filter driers, consider the following best practices. First, regularly check and replace the filter drier according to the manufacturer's recommendations. Clogged or saturated filter driers can impact system performance and lead to costly repairs. Second, monitor system pressures and temperatures to identify any irregularities that may indicate a failing filter drier. Lastly, ensure that the system is properly charged to prevent excess moisture accumulation, as a well-maintained system reduces stress on the filter drier.

By following these tips, you can enhance the reliability of your HVAC systems and prolong the life of your refrigeration filter driers. Regular maintenance not only improves performance but also contributes to energy efficiency, ultimately saving on operating costs.