In the realm of HVAC maintenance, the Aircon Access Valve plays a pivotal role in ensuring optimal system performance. According to Mark Thompson, a leading HVAC technician with over 20 years of experience, "Proper utilization of the Aircon Access Valve is essential for efficient refrigerant management, which ultimately extends the lifespan of HVAC systems." This statement underscores the importance of understanding and effectively using the Aircon Access Valve during routine maintenance tasks.

The Aircon Access Valve serves as a gateway for technicians to monitor refrigerant levels, perform necessary adjustments, and facilitate troubleshooting without compromising system integrity. With rising energy costs and increasing demands for efficiency, mastering the use of this vital component is more crucial than ever. Additionally, regular maintenance involving the Aircon Access Valve ensures that HVAC systems operate at peak efficiency, thereby reducing environmental impact and operational costs.

In this guide, we will explore the proper techniques to utilize the Aircon Access Valve for effective HVAC maintenance, highlighting best practices and common pitfalls to avoid. By following these guidelines, technicians can optimize system performance and enhance the overall reliability of HVAC installations.

Aircon access valves play a crucial role in the efficient maintenance of HVAC systems by enabling technicians to perform essential diagnostic and service tasks without compromising the system's integrity. These valves facilitate safe access to refrigerant lines, allowing for pressure readings and refrigerant charging or recovery. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), proper management of refrigerant levels is vital; an estimated 30% of system inefficiencies stem from improper refrigerant charge. This highlights the importance of using access valves correctly to monitor and adjust refrigerant levels.

Understanding the functionality of aircon access valves also contributes to effective leak detection and system diagnostics. The International Institute of Ammonia Refrigeration (IIAR) recommends regularly checking access valves for leaks, as even minor leaks can significantly affect system performance and energy efficiency. In fact, studies suggest that addressing refrigerant leaks can lead to a potential energy saving of up to 20%. By utilizing access valves for routine maintenance, technicians can ensure optimal operation and extend the lifespan of HVAC systems, ultimately contributing to reduced operational costs and enhanced environmental sustainability.

This bar chart illustrates the average efficiency of HVAC maintenance when using aircon access valves properly. The data shows how different maintenance practices impact system performance, specifically measured in energy consumption reduction (%). Efficient use of access valves can lead to notable improvements in HVAC systems.

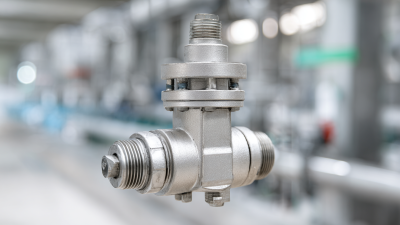

Air conditioning systems rely on access valves for efficient maintenance and troubleshooting. There are several key types of aircon access valves, each designed for specific applications within HVAC systems. The most common types include manifold access valves, service port valves, and custom refrigerant access valves.

Manifold access valves facilitate the connection of pressure gauges and allow technicians to monitor system pressures, ensuring optimal performance. Service port valves, typically integrated into the refrigeration lines, provide easy access for refrigerant charging and recovery, making it essential for routine maintenance.

In addition to these, custom refrigerant access valves are tailored to unique systems, allowing specialized operations such as refrigerant adjustments and system repairs. Each type of valve plays a crucial role in maintaining the air conditioning system's efficiency, helping technicians to diagnose issues without extensive disassembly.

Understanding the specific applications of these access valves ensures that HVAC professionals can perform their tasks effectively, prolong the lifespan of the equipment, and maintain climate control efficiency. Proper use of these valves is essential for effective HVAC maintenance, contributing to energy savings and reliable system operation.

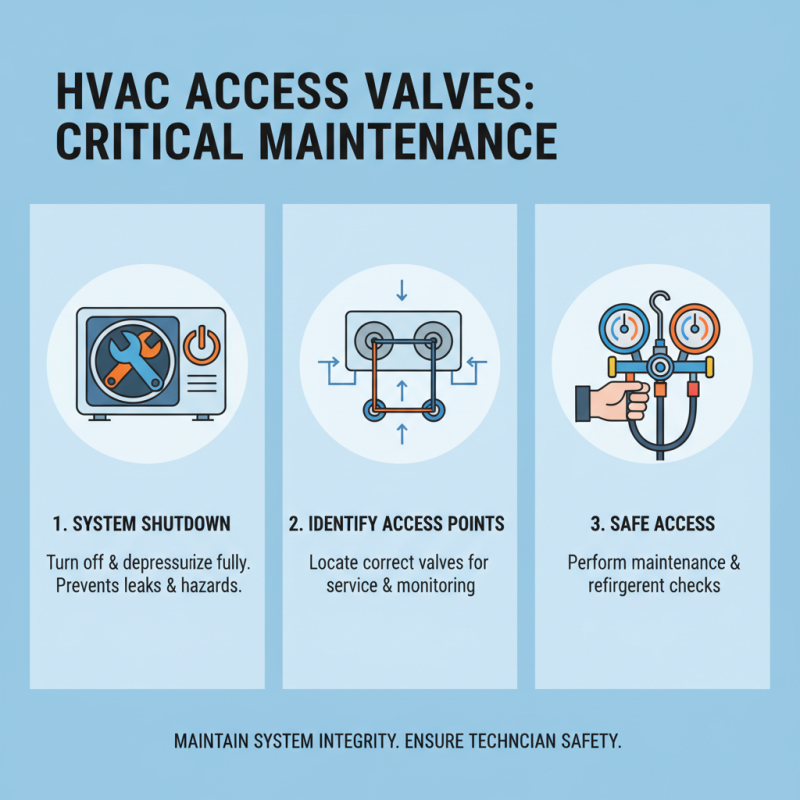

Access valves are critical components in HVAC systems, allowing for vital maintenance without compromising the system's integrity. To properly utilize access valves, first ensure that the system is turned off and fully depressurized. This safety step prevents refrigerant leaks and protects technicians from potential hazards. Begin by identifying the correct access points based on the system's layout, as this will facilitate both service and refrigerant monitoring.

Once the access valves are located, carefully remove the valve caps using the appropriate tools. If any resistance is encountered, do not force the caps, as this may damage the valve. Instead, inspect the valve for debris or signs of wear. After the preparation is complete, connect the necessary service tools, such as pressure gauges or refrigerant recovery units, ensuring a secure fit to prevent leakage. During maintenance, maintain awareness of the pressure and temperature readings, as these metrics are essential in diagnosing system health and performance.

After the maintenance tasks are completed, smoothly disconnect the service tools and replace the valve caps securely. This step is vital to avoid air and moisture intrusion, which can significantly affect system efficiency. Finally, double-check the access points for any signs of leakage and ensure that everything is back to its original state. By following these steps, technicians can effectively utilize access valves, ensuring efficient HVAC maintenance that prolongs system lifespan and functionality.

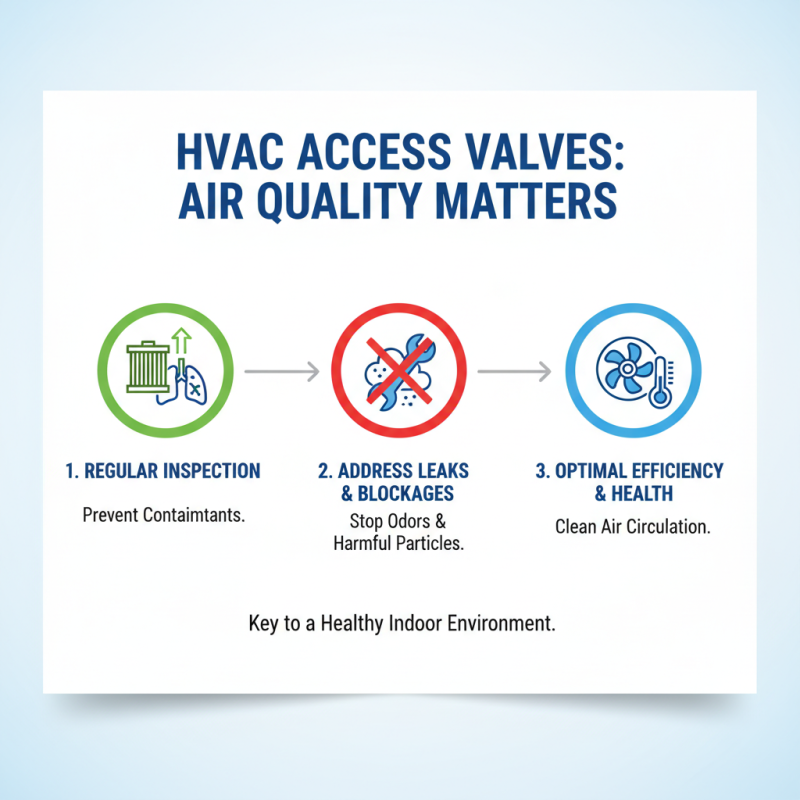

Maintaining air quality while utilizing access valves in HVAC systems is crucial for ensuring both efficiency and health benefits. Access valves play a significant role in servicing and maintaining refrigeration systems, allowing technicians to check refrigerant levels and perform necessary diagnostics without compromising the system's integrity. To keep indoor air quality high, it is essential to regularly inspect and maintain these valves. Any leaks or blockages should be addressed immediately to prevent contaminants from entering the system, which can lead to the circulation of unpleasant odors and harmful particles indoors.

Additionally, during maintenance work involving access valves, it is advisable to use appropriate filtration methods. Utilizing clean, high-efficiency particulate air (HEPA) filters can help trap airborne particles that may be disturbed during servicing. When performing maintenance, ensure that the workspace is well-ventilated and that air pollutants are minimized. The use of vacuum-sealed tools can also prevent the escape of contaminants, ensuring that the overall environment remains clean and safe. Implementing these best practices not only enhances the performance of HVAC systems but also contributes significantly to a healthier indoor atmosphere.

When working with HVAC access valves, it's crucial to avoid common mistakes that can lead to inefficiencies or costly repairs. One of the most frequent errors is neglecting to check the valve's compatibility with the system. Using an access valve that doesn’t match the HVAC system can cause leaks or pressure issues. Always ensure that the specifications align with the manufacturer's guidelines before proceeding with maintenance.

Another pitfall is failing to properly clean the area around the access valve before opening it. Dirt and debris can contaminate the system, leading to reduced efficiency or even system failure. It's essential to ensure the surrounding area is clean to maintain optimal performance.

**Tips:** Always have the right tools ready to avoid unnecessary delays and ensure everything is in proper condition before starting your work. Additionally, take time to review the owner's manual for specific instructions related to access valves on your unit. This will help you avoid common pitfalls and enhance the efficiency of your HVAC system maintenance.

| Mistake | Description | Consequences | Prevention Tips |

|---|---|---|---|

| Not Vacuuming the System | Failing to remove moisture and air before recharging refrigerant. | Reduced efficiency and potential damage to the compressor. | Always vacuum the system to remove air and moisture before refilling. |

| Overtightening Access Valve Caps | Applying excessive force to access valve caps can damage seals. | Potential refrigerant leaks leading to system inefficiency. | Tighten caps just enough to secure them without excessive force. |

| Ignoring Safety Protocols | Neglecting to wear appropriate safety gear while handling refrigerants. | Risk of injury or health problems due to exposure. | Always use personal protective equipment (PPE) when working with HVAC systems. |

| Using Incorrect Tools | Employing tools not designed for HVAC access valves can lead to malfunction. | Increased wear on components and possible system failure. | Always use manufacturer-recommended tools for repairs and maintenance. |

| Not Checking for Leaks | Failing to check for refrigerant leaks after maintenance tasks. | Loss of refrigerant and efficiency, potential legal issues. | Use leak detection methods to ensure there are no leaks post-maintenance. |