In the realm of mechanical engineering, the significance of the Motor Cooling Fan Blade is often understated yet crucial for optimal performance. Dr. Emily Johnson, a leading expert in thermal management systems, emphasizes, "The efficiency of a motor largely hinges on the design and functionality of its cooling fan blades.” This statement highlights the pivotal role that these blades play in maintaining the ideal operating temperatures of motors, thereby preventing overheating and ensuring longevity.

Motor Cooling Fan Blades are engineered components designed to manage heat dissipation effectively within various applications, ranging from industrial machinery to consumer electronics. By facilitating airflow and enhancing cooling processes, these blades not only protect motors from thermal stress but also contribute to energy efficiency. As technology continues to advance, understanding the intricacies and importance of Motor Cooling Fan Blades becomes essential for engineers and manufacturers striving to optimize their designs and improve overall operational efficiency.

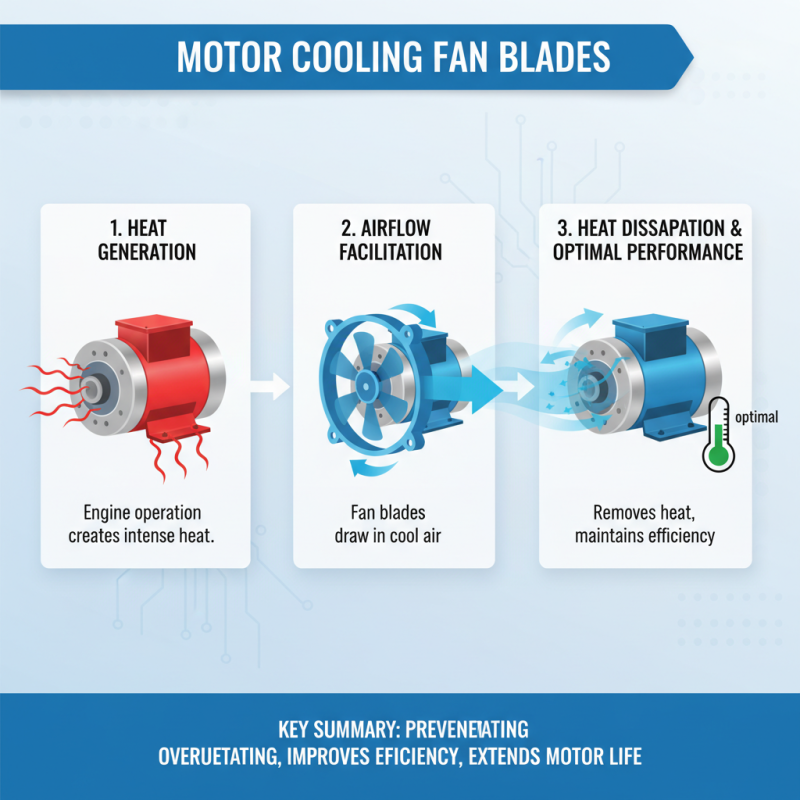

Motor cooling fan blades play a crucial role in maintaining the optimal temperature of an engine or motor. These blades are designed to facilitate airflow, which helps dissipate heat generated during operation. When an engine runs, it generates significant amounts of thermal energy, and without proper cooling, this heat can lead to various issues, such as overheating, decreased efficiency, and even mechanical failure. The fan blades are strategically positioned to maximize airflow, effectively drawing heat away from the motor and allowing it to function smoothly.

Understanding the construction and design of motor cooling fan blades is essential for appreciating their function. Typically made from durable materials like plastic or metal, these blades are shaped aerodynamically to increase their efficiency in moving air. The pitch of the blades, the angle at which they are set, is also critical; it determines how much air is pushed through and impacts overall cooling performance. Additionally, the size and number of blades can vary based on the specific application, ensuring that different motors receive adequate cooling. This engineering ensures longevity and reliability, highlighting the importance of these seemingly simple components in motor performance.

Motor cooling fan blades play a vital role in maintaining engine efficiency by regulating the temperature of the engine and preventing overheating. As the engine operates, it produces a significant amount of heat, which must be dissipated to ensure optimal performance. The cooling fan, positioned strategically within the engine compartment, circulates air around the radiator, where coolant is cooled before returning to the engine. This enhanced airflow is crucial, especially during high-demand situations, such as heavy acceleration or when climbing steep inclines.

The design and functionality of the motor cooling fan blades significantly impact the overall cooling system's efficiency. Both the shape and material of the blades affect how effectively air can be moved through the engine compartment. A well-designed fan blade can improve air circulation, helping to maintain the engine at its ideal operating temperature. In turn, this contributes to better fuel efficiency, reduced emissions, and prolonged engine life. As engines become more complex and performance-driven, the importance of reliable and efficient cooling systems, bolstered by effective motor cooling fan blades, cannot be overstated.

Motor cooling fan blades play a crucial role in various mechanical systems, particularly in automotive and industrial applications. There are several types of motor cooling fan blades, each designed for specific purposes. Axial fan blades are commonly utilized in cooling systems due to their efficient airflow, making them ideal for environments where the cooling needs are moderate to high. According to a recent report by the Engine Cooling Society, axial fans account for approximately 60% of the market share in automotive cooling systems, primarily because of their simplicity and effectiveness.

Centrifugal fan blades, on the other hand, are better suited for applications requiring high pressure and low airflow. They are widely used in HVAC systems and industrial processes. The efficiency of centrifugal fans can be up to 90%, according to data from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). These fans operate by drawing air into the center and forcing it outward, resulting in a higher pressure capable of overcoming system resistance. Therefore, the choice between axial and centrifugal fan blades is essential for optimizing performance based on the specific cooling requirements of the application.

In specialized fields, such as aerospace and high-performance automotive engineering, advanced materials like composites and carbon fiber are being utilized to enhance the strength-to-weight ratio of fan blades. This trend is supported by a report from the Composite Industry Association, which notes a 25% increase in the adoption of composite materials in fan design over the past five years. These innovations not only improve efficiency but also contribute to reducing energy consumption in cooling systems, thereby aligning with global sustainability goals.

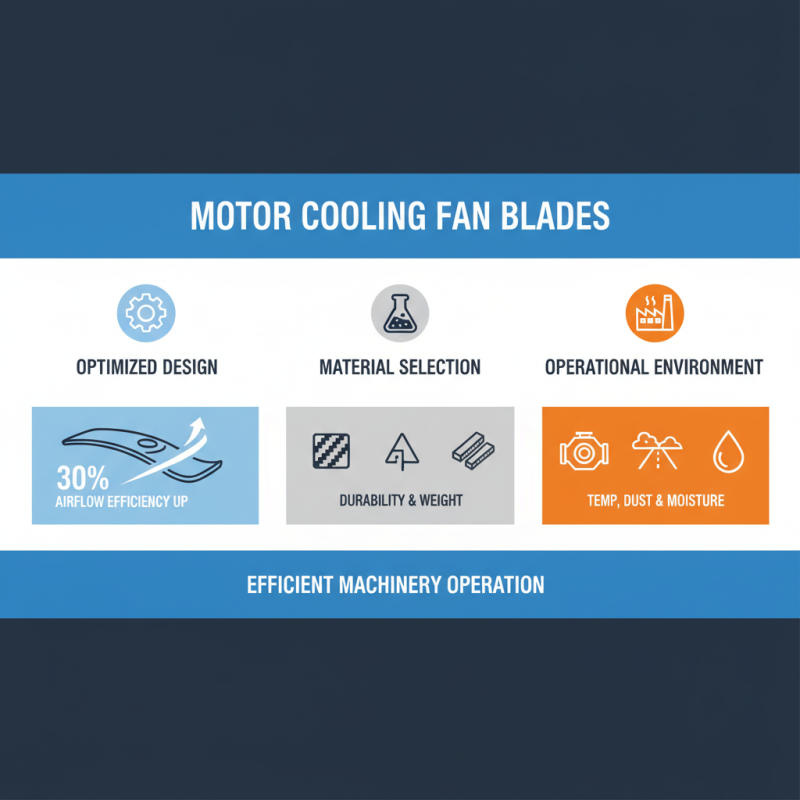

Motor cooling fan blades play a crucial role in the efficient operation of various machinery, particularly in automotive and industrial applications. The performance of these fan blades can be significantly influenced by several factors, including the blade design, material selection, and operational environment. According to a report by the International Journal of Mechanical Engineering, optimized blade design can improve airflow efficiency by up to 30%, showcasing the importance of precise engineering in fan blade production.

Material choice is another vital component that affects fan blade performance. Lightweight materials such as composite plastics or aluminum alloys are preferred for their strength-to-weight ratio, which enhances cooling capacity without adding excessive load on the motor. A study from the Advanced Materials Research states that using high-strength materials can reduce fatigue failures and prolong the life of motor cooling systems by 20%. Furthermore, the operating environment, including temperature fluctuations and dust accumulation, can impact fan blade effectiveness, necessitating regular maintenance to ensure optimum airflow.

**Tips:** Regularly inspect your cooling fan blades for debris buildup and wear, as these can hinder performance. Additionally, consider using fan blades made from advanced materials that offer durability and efficiency, which could lead to significant long-term savings on maintenance and energy costs.

Maintaining motor cooling fan blades is crucial for ensuring optimal performance and extending their lifespan. Regular maintenance can help prevent excessive wear and tear, which can lead to overheating and potential system failures. One of the key aspects of maintenance is to keep the blades clean from dust and debris that can accumulate over time. This buildup can affect airflow, reducing the cooling efficiency of the motor. Use a soft cloth or a mild detergent solution to wipe the blades clean, ensuring they are free from any obstructions.

Another important tip for maintaining your motor cooling fan blades is to regularly check for any signs of damage or wear. Look for cracks, bends, or breaks in the blades, as these can significantly impact performance. If any damage is found, consider replacing the blades promptly to avoid further issues. Additionally, ensure that the fan is properly lubricated and that all screws and bolts are tightened to prevent vibrations, which can lead to further deterioration. Addressing these simple maintenance tasks can greatly enhance the longevity and reliability of your motor cooling fan system.

| Dimension | Description | Importance | Maintenance Tips |

|---|---|---|---|

| Material | Typically made from thermoplastic or metal | Durability and resistance to heat | Regularly inspect for cracks |

| Blade Shape | Varies based on design; affects airflow | Optimizes cooling efficiency | Ensure blades are free of debris |

| Fan Speed | Measured in RPM (Revolutions Per Minute) | Affects cooling performance | Lubricate motor bearings regularly |

| Noise Level | Can indicate wear or imbalance | Assess functionality | Check alignment and secure mounting |

| Lifespan | Usually 5-10 years under normal conditions | Prevents overheating | Replace if efficiency declines |