In the fast-evolving landscape of modern manufacturing, the efficiency and effectiveness of production processes are paramount, driving the need for advanced technologies. One such innovation is the Filter Dryer Refrigerator, a pivotal component in the processing and manufacturing sectors. According to a recent report by MarketsandMarkets, the global industrial refrigeration market is projected to reach $29 billion by 2025, indicating a significant demand for efficient cooling solutions while ensuring product quality and safety. The Filter Dryer Refrigerator not only enhances energy efficiency but also plays a crucial role in moisture removal, thereby preventing contamination and ensuring optimal performance in various applications. As industries continue to prioritize sustainability and operational excellence, the functionality of the Filter Dryer Refrigerator stands out as a key contributor to achieving these goals while adapting to the unique requirements of modern manufacturing environments.

Filter dryer refrigerators play a pivotal role in modern manufacturing by enhancing operational efficiency and product quality. According to recent industry reports, the integration of filter dryer technology in refrigeration systems can reduce moisture content in pharmaceuticals by upwards of 30%, thereby minimizing production inconsistencies and waste. This capability is essential in sectors where even the smallest variations can compromise product integrity.

Furthermore, the energy efficiency of filter dryer refrigerators significantly contributes to reducing operational costs. Research indicates that these advanced systems can improve energy savings by 20-40% compared to traditional refrigeration methods. This reduction not only leads to lower energy bills but also supports sustainability initiatives, as manufacturers strive to decrease their carbon footprint in response to growing environmental regulations. As industries continue to adapt to these challenges, the role of filter dryer refrigerators remains crucial in maintaining high standards of manufacturing efficiency.

| Feature | Importance | Impact on Manufacturing Efficiency |

|---|---|---|

| Moisture Removal | Prevents product spoilage | Increases product shelf life, reducing waste |

| Temperature Control | Ensures consistent processing conditions | Enhances process quality and consistency |

| Energy Efficiency | Reduces operational costs | Improves overall profitability |

| Space Optimization | Maximizes use of available space | Facilitates better workflow and accessibility |

| Automated Controls | Allows for precision management | Reduces human error and increases reliability |

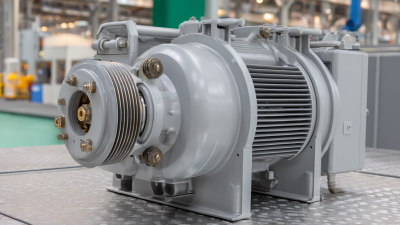

In modern manufacturing, filter dryer refrigerators play a crucial role in ensuring product quality and operational efficiency. These systems are designed to remove moisture from various materials, which is essential in industries such as pharmaceuticals, food production, and electronics. When assessing the performance of filter dryer refrigerators, key metrics include energy efficiency, drying capability, and maintenance requirements.

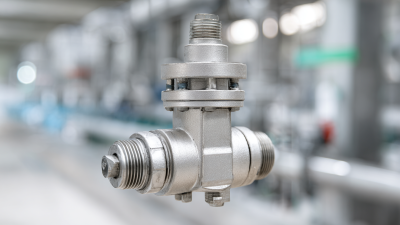

To enhance the effectiveness of filter dryer refrigerators, one tip is to regularly monitor temperature and humidity levels within the system. This ensures optimal drying conditions and helps identify potential issues before they escalate. Additionally, investing in advanced monitoring technology can provide real-time data, enabling manufacturers to adjust operations dynamically and maintain peak performance.

Another important aspect is the regular maintenance of these systems. Schedule routine inspections and cleanings to prevent dust accumulation and mechanical failures. This proactive approach not only prolongs the lifespan of the equipment but also ensures consistent product quality, ultimately leading to higher productivity and lower operational costs.

In modern manufacturing, the implementation of filter dryer refrigerators has shown significant potential in optimizing production efficiency and cost management. These systems not only enhance the quality of products by ensuring moisture control but also reduce operational costs associated with drying and cooling processes. By integrating filter dryer refrigerators into production lines, manufacturers can achieve a dual benefit: improved product durability and minimized energy consumption. This creates a more sustainable manufacturing process while maintaining competitive pricing in the market.

Conducting a cost-benefit analysis reveals that the initial investment in filter dryer refrigerators can be recouped through reduced energy bills and lower maintenance costs. Although the upfront capital may seem substantial, the longevity and efficiency of these systems often lead to a faster return on investment. Additionally, manufacturers that adopt this technology may see a decrease in waste production, as moisture-related defects are less likely to occur, further enhancing profitability. Overall, the strategic integration of filter dryer refrigerators not only advances production quality but also aligns economic benefits with sustainability goals in manufacturing.

In modern manufacturing, the integration of advanced refrigeration technology plays a pivotal role in enhancing product quality and extending shelf life. Filter dryer refrigerators are specifically designed to maintain optimal temperatures while filtering out impurities and moisture from the refrigerant. This not only ensures consistent cooling but also minimizes the risk of contamination, which is crucial for industries such as food processing, pharmaceuticals, and cosmetics. By maintaining a stable environment, these systems contribute significantly to preserving the integrity of the products throughout the manufacturing and storage processes.

Moreover, the technological advancements in refrigeration systems have introduced features such as temperature control, humidity regulation, and energy efficiency. These enhancements allow manufacturers to monitor and adjust conditions in real-time, which is essential for products sensitive to slight variations in temperature and humidity. As a result, companies can ensure that their products retain their freshness and efficacy for a longer duration, ultimately leading to higher customer satisfaction and reducing waste due to spoilage. The impact of these innovations underscores the importance of investing in advanced refrigeration solutions to enhance both product quality and operational efficiency in manufacturing.

In recent years, advancements in filter dryer refrigeration technologies have played a crucial role in modern manufacturing processes. As industries aim for greater efficiency and sustainability, these systems are evolving to meet the demands of various sectors. Future trends indicate a shift towards more energy-efficient models equipped with smart technology, enhancing both performance and ease of use. Manufacturers are increasingly adopting IoT-enabled refrigerators that facilitate real-time data monitoring, allowing for proactive maintenance and reducing downtime.

Moreover, the integration of eco-friendly refrigerants is becoming a priority, aligning with global sustainability goals. Innovations in materials and design aim to minimize environmental impact while maximizing cooling efficiency. These developments not only contribute to reduced energy consumption but also enhance product quality, ensuring that sensitive items are stored under optimal conditions. As the industry moves forward, the emphasis on modular and scalable solutions will further benefit manufacturers, allowing for greater flexibility to adapt to changing production needs.