In the ever-evolving HVAC industry, the importance of efficient cooling systems cannot be overstated, with AC condenser motors playing a crucial role in maintaining optimal indoor environments. According to a recent report by the U.S. Department of Energy, HVAC systems account for approximately 40% of the total energy consumption in residential buildings, underscoring the need for high-performance components like the AC condenser motor. These motors are designed to enhance system reliability and efficiency, contributing to lower energy costs and improved environmental sustainability. Furthermore, as the demand for energy-efficient solutions continues to rise, industry experts predict that the market for AC condenser motors will witness significant growth, with a projected increase of 5.4% annually through 2028. This comprehensive guide delves into the features, benefits, and applications of the best AC condenser motors, offering valuable insights for homeowners and HVAC professionals alike.

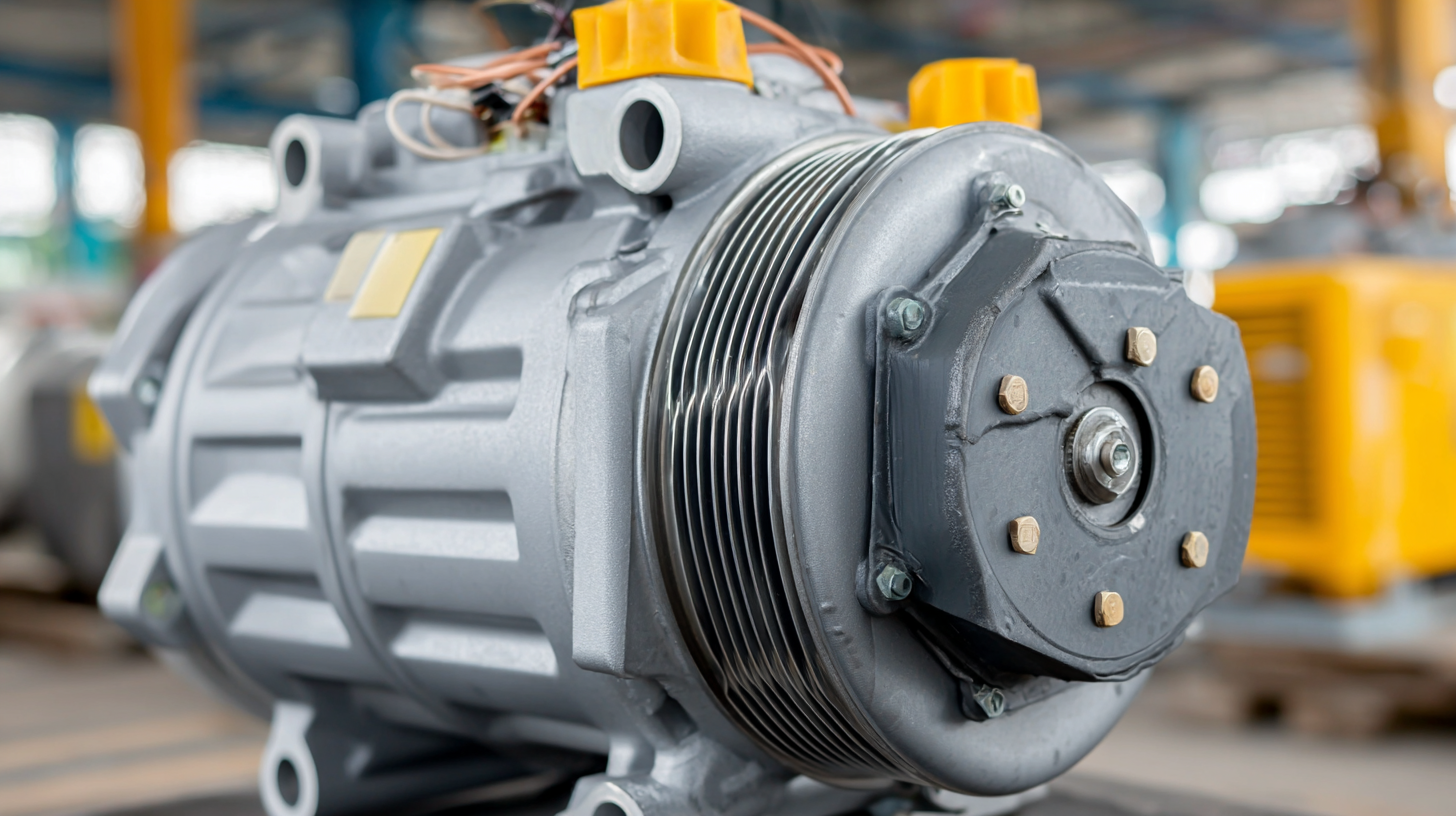

When choosing the right AC condenser motor, understanding its key features is essential for ensuring optimal performance and longevity. One fundamental aspect to consider is the motor's efficiency. Look for motors that are classified as high-efficiency, as they consume less energy and can significantly reduce your electricity bills. Additionally, consider the horsepower rating of the motor, which indicates its power output. It's crucial to select a motor that matches the specifications of your air conditioning unit to prevent overheating and excessive wear.

Another important feature to evaluate is the motor's durability. High-quality materials and weather-resistant designs can enhance the motor’s lifespan, especially in harsh environments. Selecting a motor with sealed ball bearings can also help maintain performance by reducing friction and wear over time.

**Tip:** Always read reviews and product specifications to ensure you're getting a reliable product. Also, don't hesitate to consult with professionals or trusted suppliers for recommendations tailored to your specific needs. Taking the time to research and select a quality AC condenser motor can lead to better performance and a cooler environment in the long run.

When searching for reliable manufacturers of AC condenser motors, it's essential to evaluate the industry players based on their reputation and product quality. An established manufacturer should have a robust history of producing durable and efficient motors that cater to a variety of applications. Look for companies that emphasize rigorous testing standards and quality control processes, as these factors greatly influence the efficiency and longevity of the motors. Checking customer reviews and testimonials can also provide valuable insights into the reliability and performance of their products.

Another key aspect to consider is the manufacturer's commitment to innovation and technology. The best AC motor manufacturers continuously invest in research and development to improve energy efficiency and performance. By offering state-of-the-art designs, they help reduce energy consumption, which is crucial in today’s eco-conscious market. Additionally, partnering with manufacturers that provide excellent customer support and technical assistance ensures that you receive not only a quality product but also the necessary guidance to optimize its use in your specific applications.

In the evolving landscape of HVAC technology, the performance of AC condenser motors is crucial, particularly under the stringent ODP (Ozone Depletion Potential) and GWP (Global Warming Potential) regulations. These standards urge the industry to adopt clean refrigerants, such as CO2, and to implement energy-saving technologies that enhance fuel economy. According to a recent study by the Department of Energy, efficient AC systems can lead to energy savings of up to 30%, highlighting the importance of choosing the right components, including high-performance condenser motors.

Testing standards for AC condenser motors are essential to ensure longevity and reliability. The National Electrical Manufacturers Association (NEMA) outlines specific testing protocols that set benchmarks for efficiency and durability. For instance, motors are often subjected to thermal and vibration tests to assess their performance under various operating conditions. Such rigorous testing is critical, as it can significantly impact the overall efficiency of HVAC systems, contributing to reduced energy consumption and lower operational costs for consumers. As the market continues to adapt to greener technologies, understanding these standards and features is key to optimizing HVAC performance.

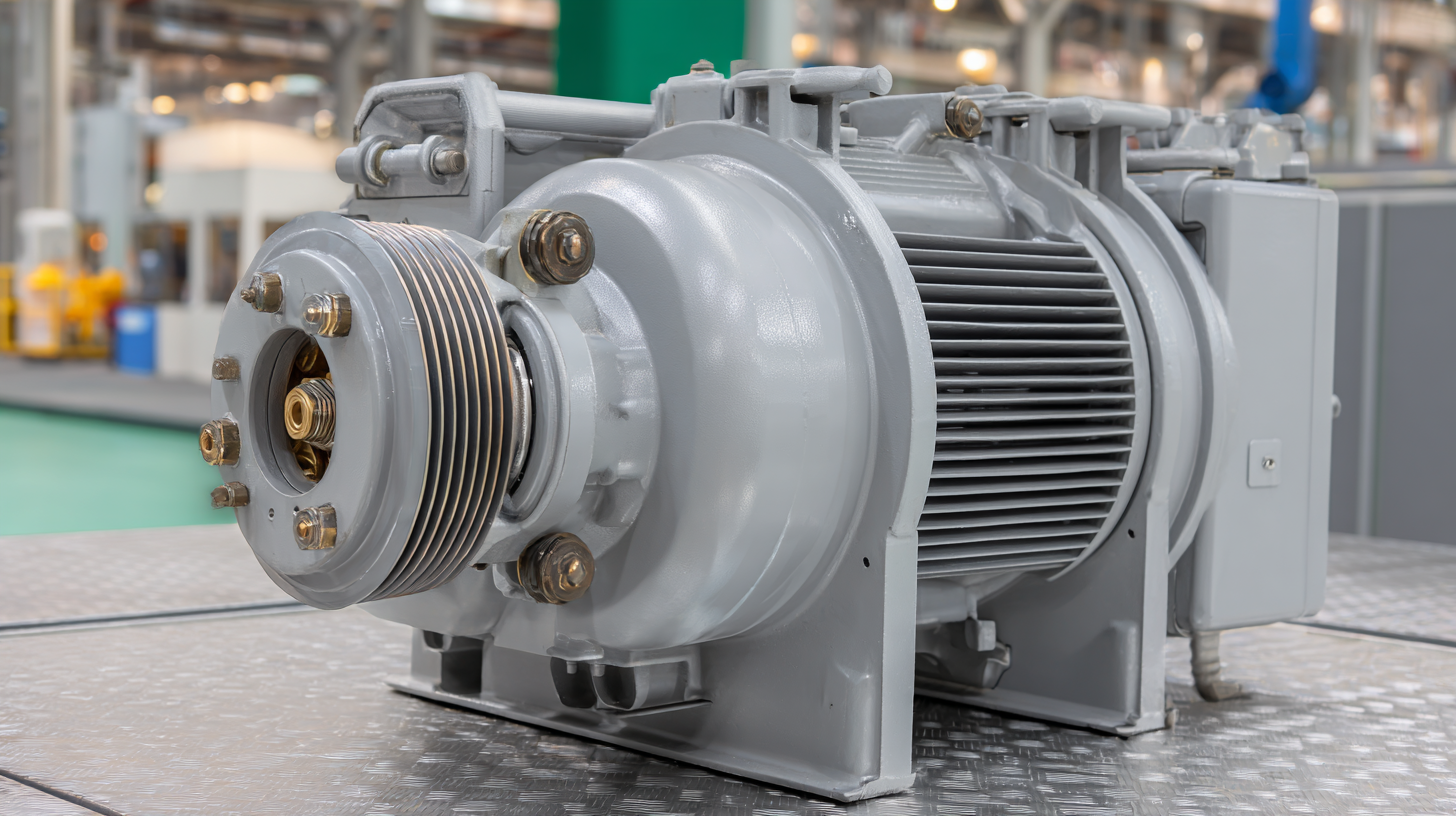

The applications of AC condenser motors are expanding significantly across various industries, driven by the growing demand for energy-efficient solutions. As certain sectors like oil and gas continue to evolve, the need for reliable and efficient motors is paramount. AC condenser motors play a crucial role in ensuring optimal performance in processes involving pumps, fans, and fluid handling systems. Their ability to deliver consistent power while reducing energy consumption is critical in environments where efficiency can lead directly to cost savings and reduced environmental impact.

Moreover, the industrial sector is witnessing a shift towards smart motor technologies that promise enhanced performance and ease of use. These advancements enable businesses to streamline operations and improve their overall output while maintaining lower operational costs. With the electricity consumed by electric motors and motor-driven systems accounting for a considerable percentage of industrial energy usage, the transition to energy-efficient motors is not merely a trend but a necessity for sustainable growth. As industries continue to adopt these innovations, the market for energy-efficient AC motors is expected to flourish, promoting both technological advancement and environmental stewardship.

| Industry | Application | Motor Type | Power Rating (HP) | Efficiency Rating (%) |

|---|---|---|---|---|

| HVAC | Air Conditioning Systems | Single-Phase | 1.5 | 85 |

| Food Processing | Refrigeration Units | Three-Phase | 3 | 90 |

| Manufacturing | Cooling Systems | Single-Phase | 2 | 88 |

| Agriculture | Irrigation Systems | Three-Phase | 5 | 89 |

| Healthcare | Ventilation Systems | Single-Phase | 1 | 87 |

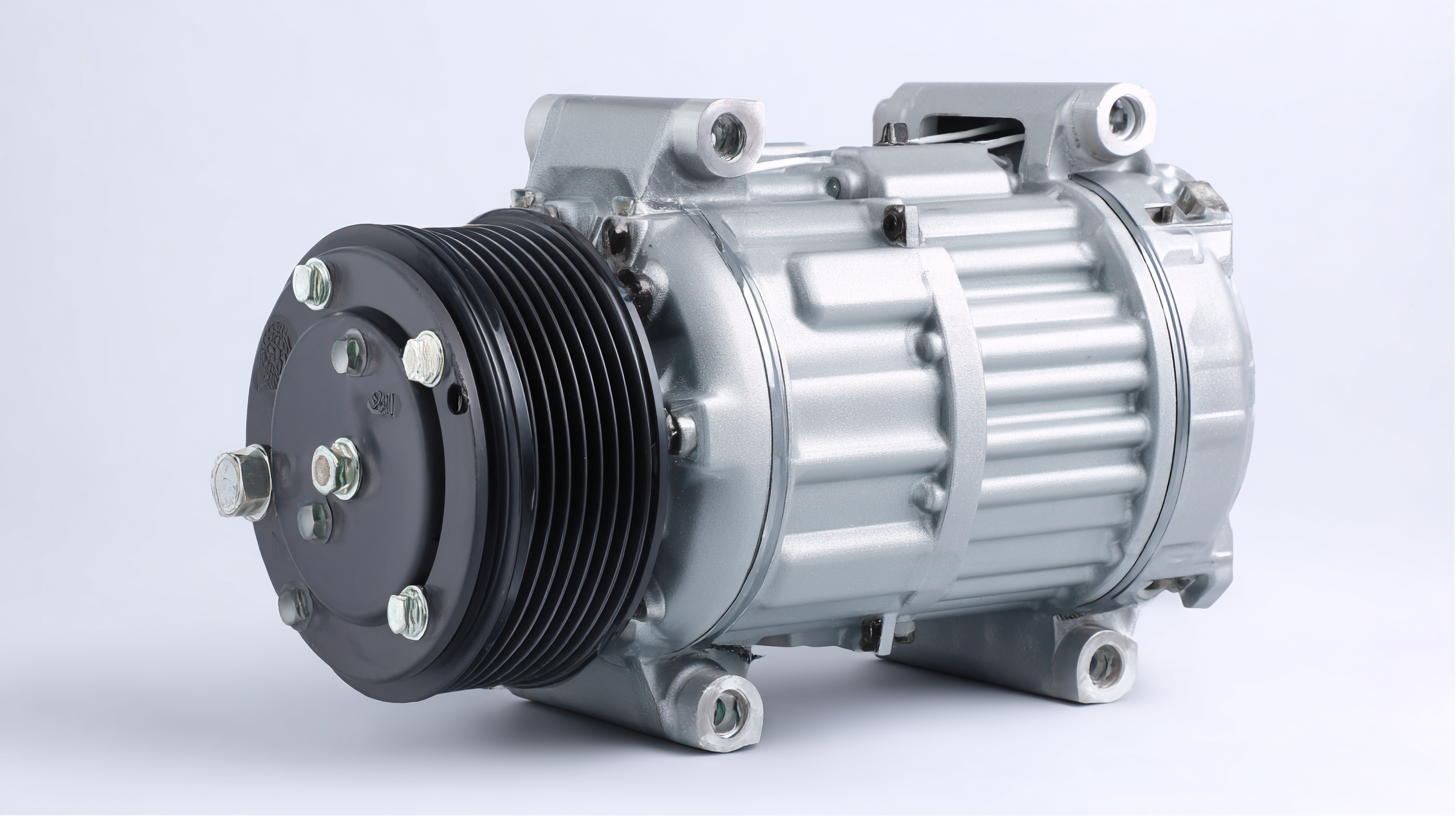

Maintaining AC condenser motors is crucial for optimal performance and longevity. According to the U.S. Department of Energy, regular maintenance can improve the efficiency of cooling systems by up to 20%. One key tip is to keep the motor clean and free from debris. Dust accumulation can lead to overheating, which can severely reduce the motor's lifespan. A simple routine of wiping down the exterior and ensuring that the surrounding area is clear can make a significant difference.

Maintaining AC condenser motors is crucial for optimal performance and longevity. According to the U.S. Department of Energy, regular maintenance can improve the efficiency of cooling systems by up to 20%. One key tip is to keep the motor clean and free from debris. Dust accumulation can lead to overheating, which can severely reduce the motor's lifespan. A simple routine of wiping down the exterior and ensuring that the surrounding area is clear can make a significant difference.

Another important aspect of maintenance is checking the motor bearings. These components can wear over time, especially in high-use scenarios. Lubricating the bearings according to the manufacturer's specifications can prevent friction-related damage. In fact, studies indicate that properly lubricated motors can operate up to 30% cooler, reducing the risk of failure. Additionally, listening for unusual noises during operation may indicate that something is amiss; addressing these issues early can save costly repairs down the line. Regular inspections and timely interventions can greatly extend the service life of your AC condenser motor.