In the realm of thermal management and fluid control systems, the selection of the appropriate Copper Capillary Tube is critical to ensuring optimal performance and efficiency. According to a report from Grand View Research, the global market for capillary tubes is projected to expand at a CAGR of 6.5% from 2021 to 2028, highlighting the increasing reliance on these components across various industries, including HVAC and refrigeration. The unique thermal conductivity properties of copper, combined with its corrosion resistance, make Copper Capillary Tubes an ideal choice for applications requiring precise fluid flow and temperature regulation. However, the process of selecting the right Copper Capillary Tube can be complex, influenced by factors such as tube diameter, length, and application specifications. This blog will provide you with 12 essential tips to guide your decision-making process, ensuring that you choose the most suitable Copper Capillary Tube for your projects.

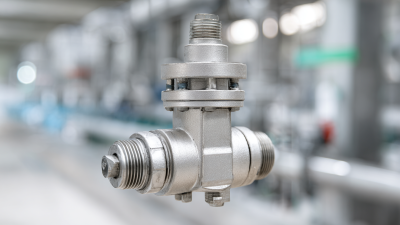

Copper capillary tubes are essential components in various applications, particularly in refrigeration, air conditioning, and plumbing systems. Their primary function is to control the flow of refrigerants and fluids, offering precise flow regulation essential for efficient system operation. Understanding the basics of these tubes is crucial for anyone involved in related projects. Typically, copper capillary tubes come in various forms, including straight tubes and coils, each serving distinct functions depending on system requirements.

When selecting the right copper capillary tube for your project, it's important to consider factors such as tube type and size. The most common types—Type K, L, and M—differ in wall thickness and pressure ratings, impacting their suitability for specific applications. Capillary tubes are particularly advantageous in HVACR systems, where they help maintain optimal fluid flow, ensuring system efficiency and longevity. By understanding the basics of copper capillary tubes, you can make informed decisions that enhance the performance of your projects, ultimately leading to successful outcomes.

When selecting the right diameter and length of a copper capillary tube for your project, it's crucial to understand the implications of these measurements on system performance. According to a report by the International Copper Association, capillary tubes play a vital role in refrigeration and air conditioning systems, impacting the efficiency and overall heat exchange process. An optimal diameter ensures that refrigerant flow is neither too restricted nor too excessive, which could lead to inefficient cooling and increased energy consumption.

One essential tip is to consider the specific needs of your application. For instance, a smaller diameter tube, typically around 0.5 mm to 1.5 mm, is suitable for systems requiring precise refrigerant control, such as in small refrigeration units. On the other hand, larger diameters (2 mm and above) might be more appropriate for commercial systems dealing with higher volumes. Additionally, length is critical; longer tubes can lead to pressure drops which adversely affect system performance. A study by ASHRAE indicates that every meter of increased length can lead to a 1-2% efficiency drop, emphasizing the need for proper length selection.

Ultimately, understanding the diameter and length interaction is key in avoiding common pitfalls. As a rule of thumb, allow for variable configurations in your designs while referring to established industry standards. This ensures that your project not only meets functional requirements but also adheres to energy efficiency guidelines that can lower operational costs in the long run.

When selecting a copper capillary tube for your projects, evaluating the material quality is paramount. The performance and longevity of these tubes depend significantly on the purity of the copper used. High-quality copper has a minimal presence of impurities, ensuring better thermal conductivity and mechanical strength. This not only enhances the effectiveness of the tube in heat transfer applications but also reduces the risk of corrosion over time, leading to a longer lifespan.

Furthermore, the manufacturing process plays a critical role in the overall quality of the capillary tubes. Tubes that have undergone rigorous quality control checks and meet industry standards will provide superior performance compared to generic options. Look for tubes that comply with specifications such as ASTM B280 or ASTM B757, which indicate a higher level of craftsmanship and reliability. Investing in quality materials not only improves the efficiency of your systems but can ultimately save on replacement costs and project delays in the long run. Prioritizing material quality in your selection process will lead to more successful outcomes in your projects.

When selecting the right copper capillary tube for your projects, understanding the thermal conductivity requirements is essential. Many modern applications, especially those involving energy-efficient construction, increasingly focus on maximizing thermal performance. Assessment of materials based on their thermal conductivity can significantly affect the overall energy efficiency of the project. For instance, some innovative insulation materials made from agricultural byproducts like rice husk ash and bagasse ash have shown promise in enhancing thermal insulation capabilities. Incorporating such sustainable options can lead to better heat retention and reduced energy consumption.

One of the key tips for choosing the right copper capillary tube is to assess the thermal requirements of your specific application. Ensure the selected tube can withstand the thermal load while maintaining efficient heat transfer. Additionally, consider the influence of the tube's diameter and length on its thermal performance. In projects exploring alternative insulation solutions, the integration of materials like sawdust in hot climates showcases the potential for enhanced thermal properties, demonstrating the importance of matching your tube selection with your project's specific thermal needs. By focusing on these factors, you can improve your project's energy efficiency and sustainability.

When selecting a copper capillary tube for your projects, cost-effectiveness is a crucial factor that cannot be overlooked. According to a 2022 report by the International Copper Association, the average lifespan of copper materials in applications like HVAC systems can exceed 50 years, illustrating the long-term performance benefits associated with initial investments. This highlights the importance of balancing price and performance in your decision-making process. Investing in higher-quality tubes may result in reduced maintenance and replacement costs over time, ultimately yielding better overall value.

One essential tip is to consider the specific requirements of your application. For instance, a thinner wall tube may be suitable for lower pressure systems, whereas thicker walls could be necessary for high-pressure scenarios. Verify the tube's specifications against industry standards like ASTM B280, which define the types and dimensions suitable for various uses. Another tip is to evaluate the supplier's reputation; reliable manufacturers often provide additional insights into performance metrics and longevity, ensuring that your capital expenditures align with functional expectations.

Lastly, don't hesitate to seek out bulk purchasing options, as economies of scale can significantly reduce unit costs. According to market analysis from Grand View Research, the global copper tubes market is projected to grow at a CAGR of 5.6% from 2023 to 2030, underscoring the rising demand and potential for competitive pricing. Mindfully navigating these factors will help you achieve a more rewarding balance between cost and performance.