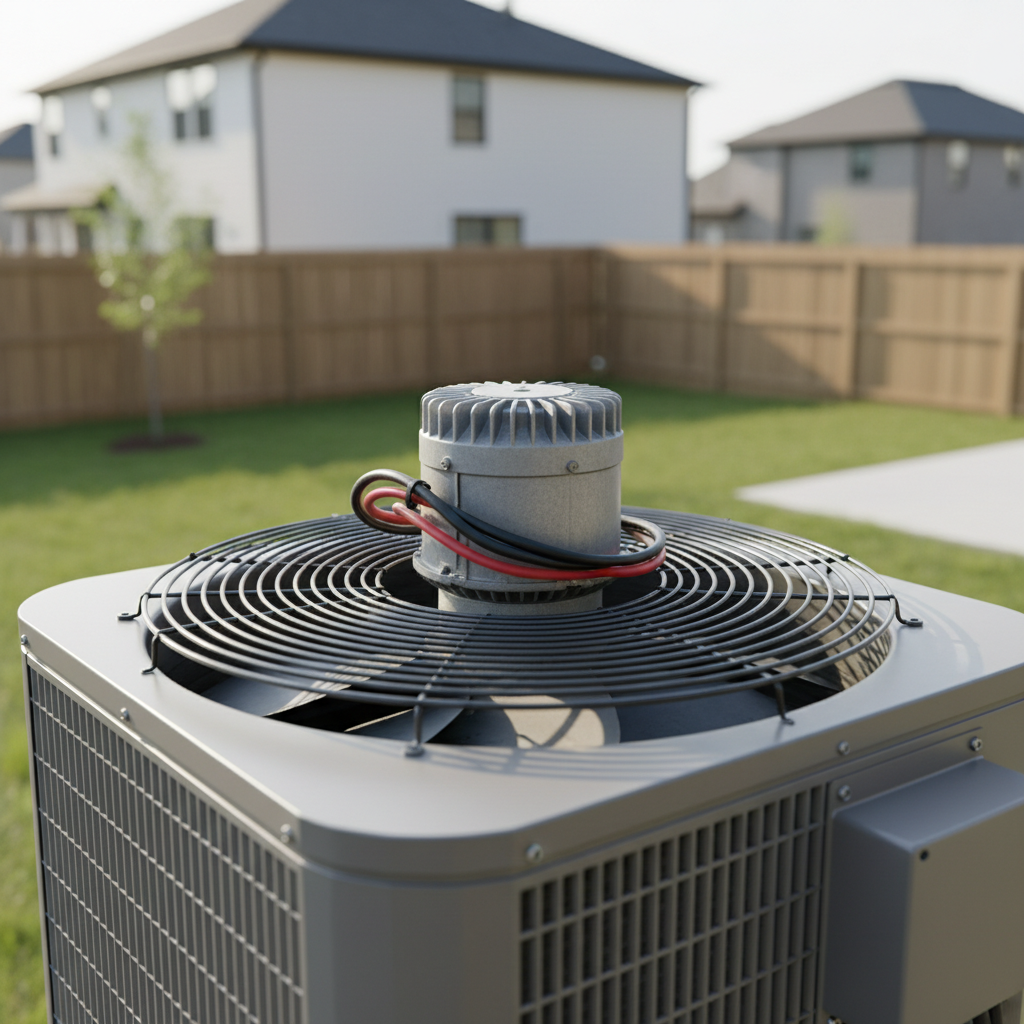

When it comes to the efficiency and functionality of air conditioning systems, the AC condenser motor plays a crucial role. This essential component is responsible for regulating the refrigerant flow and ensuring your AC unit performs at its best. Understanding the intricacies of AC condenser motors is vital for homeowners and HVAC professionals alike, as it can lead to better maintenance practices and improved energy efficiency.

In this article, we will explore the top 10 essential facts about AC condenser motors that everyone should know. From their operational mechanics to common troubleshooting tips, we aim to provide a comprehensive insight into this often-overlooked component. By grasping these key pieces of information, readers will not only enhance their knowledge but also empower themselves to make informed decisions regarding their air conditioning systems. Whether you're a DIY enthusiast or simply looking to understand your HVAC setup better, this guide serves as a valuable resource on the importance of the AC condenser motor.

The AC condenser motor plays a crucial role in the HVAC system, acting as the driving force behind the efficient operation of air conditioning units. These motors are responsible for circulating air over the condenser coil, allowing for the essential heat exchange process that cools the refrigerant and ultimately cools indoor spaces. According to a report by the U.S. Department of Energy, optimizing the performance of AC systems, including the condenser motor, can improve overall energy efficiency by up to 30%. This makes the selection and maintenance of high-quality condenser motors critical for both residential and commercial HVAC applications.

Furthermore, understanding the specifications of AC condenser motors is vital for ensuring compatibility and performance within HVAC systems. Most modern motors operate using variable speed technology, which allows for greater energy savings and improved comfort levels in controlled environments. A recent study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that high-efficiency motors can reduce annual energy consumption by approximately 20%, making them a valuable investment for energy-conscious consumers. Upgrading to a more efficient motor not only contributes to lower utility bills but also supports broader sustainability goals by reducing overall energy demand in HVAC systems.

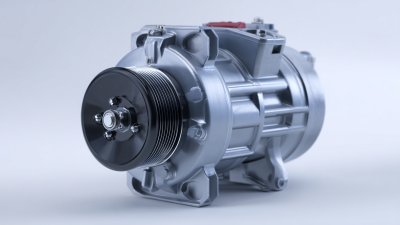

When selecting a high-quality AC condenser motor, there are several key features to consider that can significantly impact performance and longevity. First and foremost, the motor's efficiency plays a crucial role in its operational cost-effectiveness. Look for models that are rated with high efficiency, such as those that meet or exceed the Energy Star standards. This ensures that the motor consumes less energy while providing optimal cooling, ultimately reducing electricity bills.

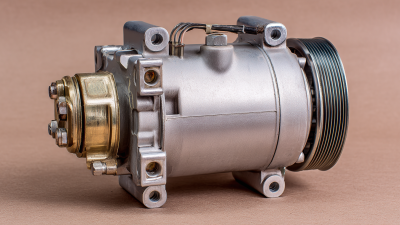

Another vital feature is the motor's durability and build quality. High-quality AC condenser motors often incorporate robust materials, such as corrosion-resistant housings and heavy-duty bearings, which enhance their lifespan under various environmental conditions. Additionally, consider the motor's noise levels; quieter motors contribute to a more comfortable home environment. Advanced designs such as permanent split capacitor (PSC) motors not only enhance efficiency but also provide quieter operation, making them a preferred choice for many homeowners looking for reliable and silent performance.

AC condenser motors are crucial for the efficient operation of your air conditioning system, but they can encounter issues just like any other appliances. Common problems include overheating, unusual noises, and failure to start. If the motor overheats, it can lead to a breakdown, so it’s essential to ensure the airflow around the unit is unobstructed. Regularly check the surrounding area for debris or obstructions that might impede the motor's ability to cool down.

When troubleshooting AC condenser motors, one effective tip is to listen for any strange sounds. If you notice grinding or rattling noises, it could indicate worn bearings or loose components. Inspecting and tightening these parts can prevent further damage. Additionally, if the motor fails to start, checking the capacitor is a good first step. A faulty capacitor can prevent the motor from turning on, so replacing it might restore functionality without requiring a full motor replacement. Regular maintenance and keen observation can keep your AC condenser motor running smoothly.

Energy efficiency in AC condenser motors is crucial for both environmental sustainability and cost savings. According to the U.S. Department of Energy, HVAC systems account for nearly 50% of a home's energy consumption. By upgrading to high-efficiency condenser motors, homeowners can potentially reduce their annual energy bills by 30%. These advanced motors utilize technologies such as variable speed drives and high-efficiency windings, which not only decrease operational costs but also minimize greenhouse gas emissions.

Tips: Regular maintenance of your AC system can significantly enhance energy efficiency. Ensure that all components, including condenser motors, are checked and cleaned at least once a year, as dirt and debris can prevent proper airflow and cooling efficiency. Additionally, consider investing in programmable thermostats that optimize your system’s operation, reducing waste during off-peak hours.

The importance of energy-efficient AC condenser motors goes beyond financial savings; they play a pivotal role in promoting a sustainable future. The Environmental Protection Agency (EPA) highlights that energy-efficient appliances, including HVAC systems, can help reduce overall energy demand and reliance on fossil fuels. By making informed choices about their AC systems, consumers can contribute to a greener environment while enjoying improved comfort and reliability in their homes.

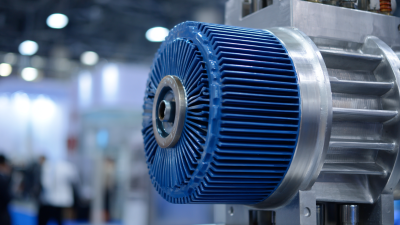

The evolution of AC condenser motor technology is pivotal as we move towards more energy-efficient and environmentally friendly solutions in the HVAC industry. Among the most promising innovations are the advancements in variable speed motors. These motors adjust their speed according to the cooling demand, which enhances energy efficiency significantly. By modulating their operation, they can maintain desired temperatures while consuming less electricity, thus reducing both operational costs and environmental impact.

Another trend gaining traction is the integration of smart technology within AC condenser motors. By utilizing IoT (Internet of Things) capabilities, these motors can be remotely monitored and controlled, allowing for real-time performance tracking and predictive maintenance. This not only prolongs the life of the equipment but also provides users with valuable data insights that can optimize operational performance. As manufacturers continue to invest in these technologies, we can expect to see a shift towards fully automated systems that improve comfort and efficiency in residential and commercial spaces alike.

| Fact No. | Description | Future Trends |

|---|---|---|

| 1 | AC condenser motors are critical for efficient heat exchange in HVAC systems. | Integration with IoT for remote monitoring and predictive maintenance. |

| 2 | Single-phase and three-phase motors are the most common types used. | Advancements in variable speed technology for enhanced efficiency. |

| 3 | Energy efficiency ratings (EER) help in selecting the right motor. | Focus on eco-friendly refrigerants improving overall system efficiency. |

| 4 | Regular maintenance is crucial for longevity and performance. | Use of AI for automated diagnostics and maintenance scheduling. |

| 5 | Heat pumps and inverter technology are gaining popularity. | Emerging designs to enhance operational versatility across climates. |

| 6 | Improved sound dampening features contribute to quieter operations. | Innovation in sound reduction technology focusing on silent motors. |

| 7 | Condenser motors can be susceptible to overheating if not sized correctly. | Smart sensors for real-time heat monitoring and adaptive operation. |

| 8 | A variety of materials are used in the construction for durability. | Sustainability initiatives aim for recycling and material reduction. |

| 9 | Mounting and vibration control affect the performance and lifespan. | Innovative mounting solutions designed to reduce wear and tear. |

| 10 | Compliance with international standards ensures safety and efficiency. | New regulations pushing for higher efficiency standards globally. |