In the realm of modern HVAC installations, efficiency and reliability are paramount, and one innovative solution that is rapidly gaining traction is the use of HVAC Copper Press Fittings. These fittings offer a seamless combination of durability and ease of installation, making them a preferred choice for many professionals in the industry. Unlike traditional soldering methods, HVAC Copper Press Fittings eliminate the need for open flames and extensive preparation, significantly reducing installation time and enhancing safety on the job site. This guide delves into the myriad advantages of incorporating HVAC Copper Press Fittings into your projects, from improved system performance to long-term cost savings, illustrating how these fittings can revolutionize your installation process while ensuring optimal efficiency. Whether you’re a seasoned installer or a newcomer to the HVAC industry, understanding the benefits of HVAC Copper Press Fittings is essential for staying competitive in today’s market.

When it comes to HVAC installations, the choice of fittings can significantly influence both efficiency and reliability. HVAC copper press fittings have emerged as a game changer in the industry, offering a wealth of advantages when compared to traditional soldered joints. One key benefit is the speed of installation; press fittings can be assembled quickly without the need for flame and soldering, which not only reduces labor time but also minimizes the risk of fire hazards and heat damage to surrounding materials.

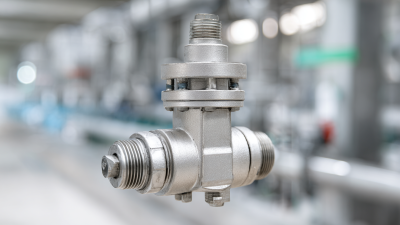

Additionally, HVAC copper press fittings provide a consistent and leak-free connection, ensuring the integrity of the system. Unlike traditional methods that rely on soldering techniques, which can be susceptible to human error, press fittings utilize a mechanical sealing mechanism that guarantees uniform compression across all joints. This leads to enhanced system performance and longevity, reducing future maintenance costs. Moreover, the precise engineering of these fittings supports cleaner installations, which is an essential criterion in today’s environmentally-conscious market.

| Advantages | HVAC Copper Press Fittings | Traditional Methods |

|---|---|---|

| Installation Speed | Faster, no flame required | Longer due to soldering process |

| Safety | Reduced risk of fire hazards | Higher risk with open flames |

| Joint Integrity | Strong and reliable connections | Can weaken over time |

| Labor Costs | Lower due to quicker installations | Higher due to skilled labor needed |

| Maintenance | Easier to inspect and maintain | More difficult to access joints |

When it comes to HVAC installations, time efficiency plays a crucial role in project completion and overall cost management. A comparative analysis of copper press fittings versus traditional soldering reveals significant advantages for professionals looking to optimize their workflow.

Copper press fittings offer a quick and straightforward installation process, requiring minimal tools and no open flame. This reduction in complexity not only speeds up the installation time but also decreases the likelihood of costly mistakes.

Copper press fittings offer a quick and straightforward installation process, requiring minimal tools and no open flame. This reduction in complexity not only speeds up the installation time but also decreases the likelihood of costly mistakes.

In contrast, soldering involves multiple steps, including surface preparation, heating, and cooling, which can extend the overall time required for pipe fittings. Moreover, the use of soldering necessitates additional safety measures due to the open flame, further complicating the installation process on job sites.

As HVAC professionals strive to enhance productivity and reduce labor costs, the adoption of copper press fittings emerges as a clear winner, showcasing how innovation can streamline operations while maintaining the integrity of the installation.

When it comes to HVAC installations, ensuring cost-effectiveness is a top priority for both contractors and homeowners. Utilizing copper press fittings can significantly enhance long-term savings. These fittings reduce the time and labor costs associated with traditional soldering methods. Since there’s no need for open flames or additional equipment, the installation process becomes quicker and safer, minimizing potential accidents and project delays.

Moreover, copper press fittings offer exceptional durability and reliability, leading to lower maintenance costs over time. Their resistance to corrosion and leaks means fewer repairs and replacements, ensuring that your HVAC system operates efficiently for years to come. This longevity not only reflects in reduced operational expenses but also contributes to sustainable energy consumption, making them a wise investment for environmentally conscious installations. By evaluating the total cost of ownership, it becomes clear that copper press fittings provide a financially advantageous solution that justifies their initial purchase price.

When it comes to HVAC installations, selecting the right connection type is crucial for ensuring durability and reliability. Copper press fittings have emerged as a leading choice among professionals in the industry, outperforming traditional solder connections and alternatives like PEX fittings in several key areas. According to recent studies, press-fit connectors not only eliminate the need for solder—reducing labor time and the risk of leaks—but also provide a stronger, more stable joint that can withstand pressure fluctuations and temperature changes.

The advantages of copper press fittings extend beyond mere convenience. Their inherent resistance to corrosion and degradation ensures a long lifespan, significantly reducing maintenance costs over time. In fact, research indicates that systems utilizing copper press fittings can last up to 50 years, compared to just 10-20 years for PEX piping. Furthermore, as the demand for reliable HVAC systems grows, the industry is witnessing a shift towards sustainable practices, with copper's recyclability making it an environmentally-friendly option. The data speaks for itself; employing copper press fittings not only optimizes installation efficiency but also enhances system longevity and performance, making it the clear choice for modern HVAC projects.

In the HVAC industry, installation efficiency is paramount. Copper press fittings have emerged as a game-changer, significantly streamlining the installation process. According to a recent report from the Copper Development Association, systems utilizing copper press fittings can reduce installation time by up to 40%. This is largely due to the ease of use and the reduced need for complex soldering techniques, allowing technicians to complete projects faster without compromising on quality.

One of the standout features of copper press fittings is the simplicity of the installation. These fittings require fewer tools and less prep time, enabling HVAC professionals to focus on other critical aspects of their work. When utilizing copper press fittings, it’s essential to ensure a proper fit—always measure twice before cutting. Additionally, consider using a torque wrench to ensure the correct press and avoid potential leaks down the line.

Tip: When replacing traditional joint techniques with copper press fittings, always verify the compatibility with existing piping to avoid mismatched sizes. Regular training on the latest tools and technologies will also enhance your team's skill set, making installations even smoother. Embracing copper press fittings not only improves efficiency but also elevates the overall quality of HVAC installations.