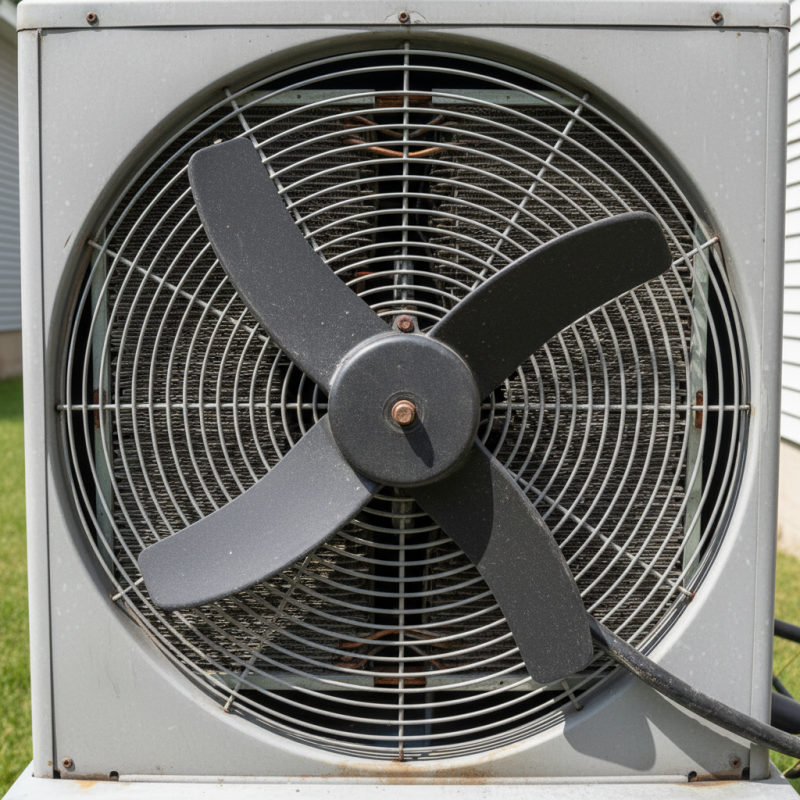

A Condenser Fan Motor plays a crucial role in cooling systems. It is often part of air conditioning units and refrigeration systems. This component ensures that heat is dissipated effectively from the condenser coil, maintaining optimal performance.

When the engine runs, the fan circulates air across the condenser. This airflow aids in removing heat absorbed from the refrigerant. Without a functioning Condenser Fan Motor, the whole cooling process can fail. It's interesting to note that even minor issues can lead to significant problems.

Regular maintenance of the Condenser Fan Motor is vital. Neglecting it could cause inefficiencies in your system. Over time, wear and tear may occur, leading to potential breakdowns. Understanding its function can help users avoid costly repairs in the future.

A condenser fan motor is an essential component in many air conditioning systems. It plays a critical role in the cooling process. Typically located outside the unit, this motor powers the fan that circulates air over the condenser coils. By doing so, it helps to remove heat from the refrigerant in the coils, enhancing the cooling efficiency.

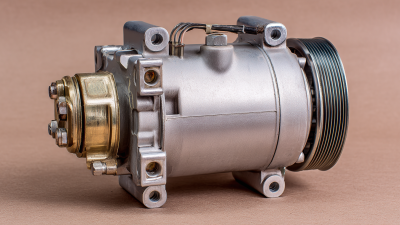

The condenser fan motor operates by converting electrical energy into mechanical energy. When the motor runs, it causes the fan blades to rotate. This rotation creates airflow that dissipates heat from the condenser. The fan motor can be controlled by the thermostat, ensuring that it only runs when needed. Sometimes, the motor may face issues like overheating or bearing failure. These problems can lead to reduced efficiency. Regular maintenance can help, but not always.

Understanding how a condenser fan motor works is key for troubleshooting. Without this motor, the cooling system may struggle to function properly. Paying attention to unusual noises from the fan or inconsistent cooling can help identify potential problems early on. Being observant can save time and energy down the line.

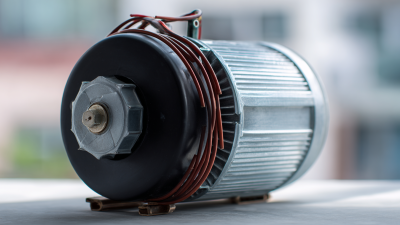

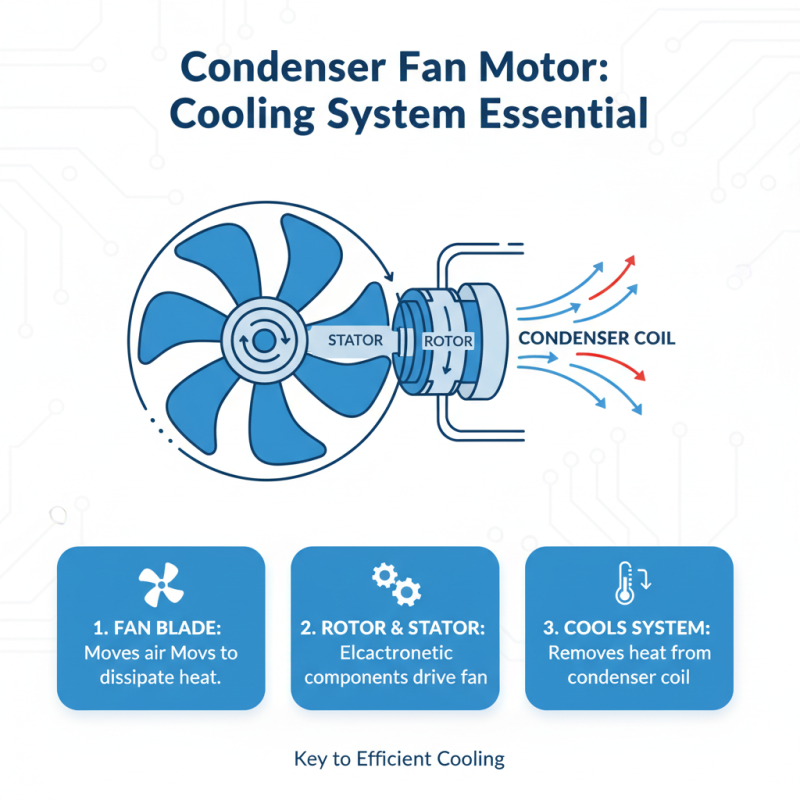

A condenser fan motor plays a crucial role in cooling systems. It helps dissipate heat from the condenser coil. Key components of this motor include the rotor, stator, and fan blade.

The rotor is the rotating part of the motor. It converts electrical energy into mechanical energy. The stator surrounds the rotor and provides a magnetic field. This field is essential for the motor’s operation. The fan blade connects to the rotor. It spins quickly to pull air across the condenser coil.

Another component is the capacitor. This small device improves starting torque. It helps the motor run more efficiently. Some motors also have thermal overload protection. This feature prevents overheating and damage. While condenser fan motors are straightforward, they can develop issues. Regular maintenance is important. Dirty blades or worn bearings can affect performance. Keeping these components in good shape is vital for optimal operation.

A condenser fan motor plays a crucial role in cooling systems, especially in air conditioning units. It circulates air over the condenser coils. This process allows heat from the refrigerant to be dissipated effectively. Often located at the back or sides of units, the fan motor varies in size and power.

How does the condenser fan motor operate? It uses electricity to turn the blades of the fan. When the system starts, the motor engages, prompting the fan to draw air. This airflow cools the condenser and aids in the refrigerant cycle. A common issue arises when the fan motor overheats or becomes noisy. These problems often indicate wear or electrical issues.

Visualizing these components helps understand their function. The fan blades spin rapidly, moving air efficiently. It's a simple mechanism, yet so essential. Maintenance is key; clean the blades and check for debris. Ignoring these tasks can lead to inefficiencies. A well-maintained motor ensures optimal performance but can sometimes fail unexpectedly. Awareness of these potential issues is necessary for effective cooling.

Condenser fan motors play a crucial role in HVAC systems. They regulate airflow over the condenser coils, helping to remove heat from refrigerants. However, these motors are prone to several issues that can impede their function. According to industry reports, approximately 20% of HVAC system failures are linked to condenser fan motor problems.

One common issue is overheating. This occurs when motors are subjected to excessive debris or poor ventilation. Over time, this can cause the motor windings to fail. A study indicated that nearly 30% of technicians reported overheating as a frequent concern. Additionally, capacitor failure is another prevalent issue. Capacitors help start the motor and keep it running efficiently. If a capacitor fails, the motor may struggle to operate or may not turn on at all.

Some motors show signs of wear, like strange noises or intermittent running. These symptoms can reflect deeper issues that often go unnoticed until it's too late. Regular maintenance is vital to extend the life of condenser fan motors. Ignoring these minor signs can lead to larger, costlier repairs. In fact, neglecting routine checks can increase repair costs by over 50%. It's clear that recognizing early warning signs is essential for HVAC longevity.

Maintaining your condenser fan motor is crucial for optimal performance. Regular checks can prevent major issues. Dust and debris can accumulate, causing overheating. Ensure the area around the motor is clean and free from obstructions. A simple visual inspection often reveals problems you can address quickly.

Another essential tip is to lubricate moving parts. A few drops of oil can go a long way, helping reduce friction. However, avoid over-lubrication. It can lead to oily buildup, which might attract dirt. Monitor noise levels. Unusual sounds could indicate wear or malfunction.

Lastly, consider monitoring the motor's temperature. If it runs hotter than usual, investigate further. Higher temperatures can shorten the motor's lifespan. Regular maintenance creates a smoother operation, but neglect can lead to costly repairs. Make time for these checks—they’re worth it in the long run.