When it comes to maintaining the efficiency and longevity of refrigeration systems, choosing the right Refrigeration Filter Drier is a crucial aspect that should not be overlooked. Refrigeration Filter Driers play an essential role in removing moisture, debris, and contaminants from the refrigerant, thereby protecting the system's components and ensuring optimal performance. However, with a variety of options available on the market, selecting the appropriate filter drier can be a daunting task for both seasoned professionals and newcomers alike.

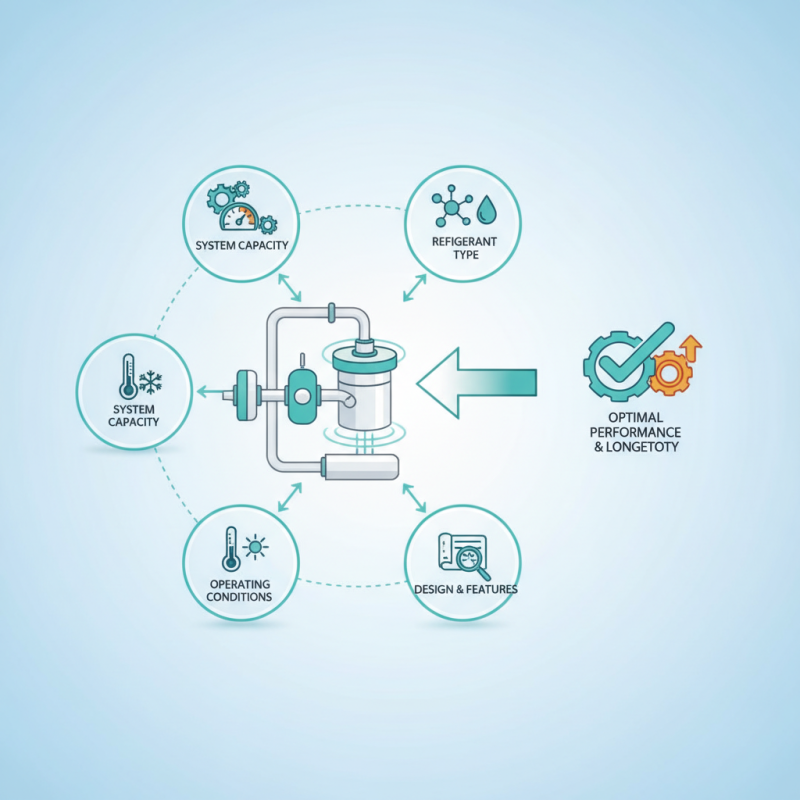

The process of choosing the right Refrigeration Filter Drier involves a thorough understanding of the specific requirements of your refrigeration system. Factors such as system capacity, refrigerant type, and operating conditions all play significant roles in determining which filter drier will best suit your needs. Additionally, it is essential to consider the design and features of different models, as these can greatly influence their effectiveness and longevity in protecting your system. By carefully evaluating these aspects, you can make an informed decision that will enhance your refrigeration system's efficiency and lifespan.

In this guide, we will explore the various factors to consider when selecting a Refrigeration Filter Drier, aiming to simplify the decision-making process and help you ensure that your refrigeration system operates at peak performance levels. Understanding these components will empower you to make a knowledgeable choice that supports the integrity and functionality of your system.

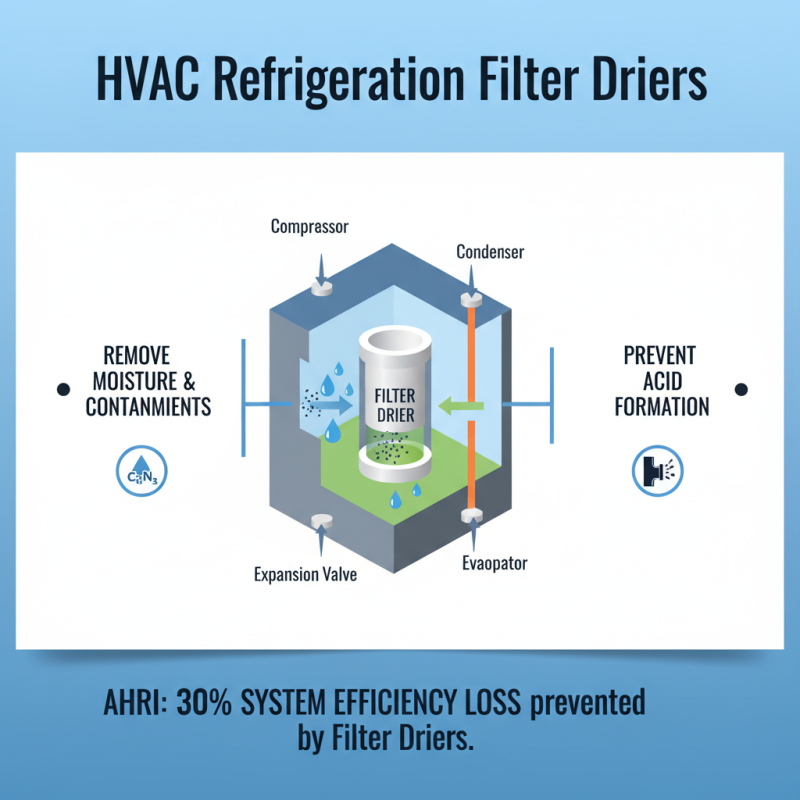

Refrigeration filter driers are essential components in HVAC systems, primarily responsible for removing moisture and contaminants from refrigerants. The significance of maintaining optimal moisture levels cannot be overstated, as water can lead to the formation of acids and other corrosive compounds, degrading the system's components. According to the Air Conditioning, Heating, and Refrigeration Institute (AHRI), moisture presence in refrigeration systems can contribute to a 30% reduction in system efficiency over time. This reveals the critical role of filter driers in ensuring the longevity and reliability of HVAC systems.

Understanding the function of refrigeration filter driers also entails recognizing their role in capturing particulate matter such as dust, debris, and system wear particles. These contaminants accumulate over time and can lead to blockages in valves and expansion devices, ultimately causing inefficiency or failure of the system. A study published by the International Journal of Refrigeration highlighted that systems employing proper filtration demonstrated a 40% lower incidence of compressor failures as compared to those without reliable filter driers. This illustrates how integral these components are in safeguarding equipment and optimizing performance, emphasizing the necessity for careful selection and maintenance.

When selecting the right refrigeration filter drier, understanding the specifications of your refrigeration system is paramount. Key specifications include the system's capacity, refrigerant type, and operating pressure. According to the Air Conditioning and Refrigeration Institute (ARI), systems using hydrofluorocarbons (HFCs) often require driers that can withstand higher pressures due to their enhanced efficiency. Furthermore, the total cooling capacity—measured in British Thermal Units (BTUs)—can dictate the size and type of filter drier needed to ensure **optimal performance** and longevity of the system.

It's also essential to consider the moisture absorption capability of the filter drier. The moisture content in a refrigeration system can lead to serious issues, including ice formation and corrosion. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends selecting a drier with a moisture capacity that exceeds the expected moisture load of the system.

Tips: Always check the manufacturer's specifications and ensure compatibility with your refrigerant type to prevent any system inefficiencies. Additionally, regular maintenance and timely replacement of the filter drier can enhance the reliability and efficiency of your refrigeration system.

When selecting a filter drier for your refrigeration system, it is crucial to understand the

various types available on the market, each designed to meet

specific operational needs. Commonly, filter driers are categorized into three main types:

standard filter driers,

bi-flow filter driers, and

liquid line filter driers.

According to a recent market analysis by the International Institute of Refrigeration, the demand for

bi-flow filter driers has seen a marked increase, particularly in applications

involving heat pumps, due to their versatility in handling refrigerants flowing in both directions.

Standard filter driers are often preferred for their straightforward application in traditional systems, effectively

removing moisture and contaminants that could otherwise compromise

the refrigerant's integrity. Conversely, bi-flow filter driers are engineered to accommodate

reversing cycle systems, making them essential in

variable refrigerant flow applications. The effectiveness of these driers is quantified through their ability to

maintain system efficiency, with studies indicating that improper filtration can lead to a 15% reduction in system performance over time.

Additionally, the choice between a liquid line filter drier and a suction line filter drier depends greatly on the specific

system design and refrigerant type. Liquid line filter driers, which are installed in the liquid line, are specifically

designed to protect the evaporator from moisture and debris, while suction line filter driers cater to the compressor's

protection by filtering refrigerant vapors. According to the latest data, the efficiency of filtration can significantly

affect the overall longevity of a refrigeration system, highlighting the importance of selecting the right

filter drier tailored to the unique demands of your application.

When selecting a refrigeration filter drier, understanding the compatibility with specific refrigerants and oils is crucial for optimal system performance. Different refrigeration systems utilize various refrigerants—such as R-410A, R-32, or R-134A—each with unique properties and requirements. Therefore, it's essential to ensure that the filter drier is designed to handle the chemical characteristics of the refrigerant being used. Using an incompatible filter drier can lead to system inefficiencies, reduced performance, and potential damage to components due to chemical reactions.

In addition to refrigerants, compatibility with lubricants is equally important. Different refrigeration systems might employ mineral oils, alkylbenzene, or synthetic oils, all of which can react differently when exposed to contaminants. Choosing a filter drier that accommodates the system's oil type helps maintain optimal lubrication, preventing wear and tear on the compressor and other moving parts. Always refer to the manufacturer specifications and guidelines to ensure both refrigerant and oil compatibility, as this can significantly extend the lifespan of the refrigeration system and enhance its overall efficiency.

This chart illustrates the compatibility of different refrigeration filter driers with common refrigerants and oils used in refrigeration systems. The data showcases the optimal compatibility ratings on a scale from 1 to 5, where 5 indicates the highest compatibility.

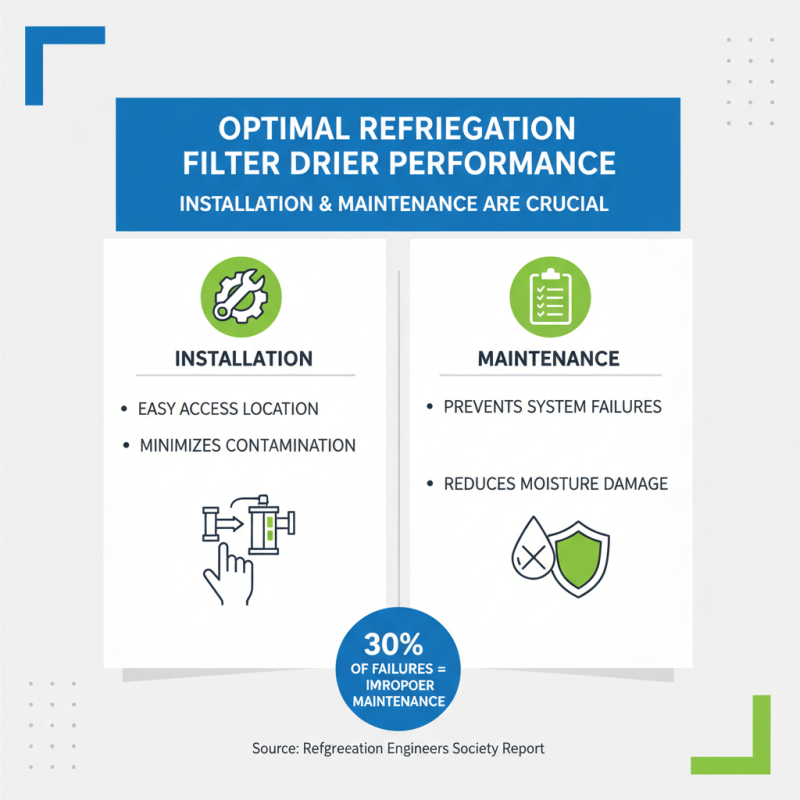

When selecting the right refrigeration filter drier, installation and maintenance are crucial factors to ensure optimal system performance and longevity. According to a recent industry report by the Refrigeration Engineers Society, nearly 30% of refrigeration system failures can be attributed to improper maintenance of filter driers. One vital consideration during installation is ensuring the filter drier is placed in a location that facilitates easy access for servicing. A well-placed filter drier minimizes the risk of contamination and wear due to particulate matter, which is essential since even a small amount of moisture can lead to significant damage over time.

Maintenance practices also play a pivotal role in the efficiency of refrigeration systems. The National Institute of Standards and Technology emphasizes the importance of regular inspection and replacement of filter driers, recommending every 12 months for commercial systems, especially those operating at higher loads. Failure to replace a clogged filter drier can lead to reduced refrigerant flow, increased energy consumption, and potential compressor failure, with the latter costing businesses thousands in repairs and lost productivity. Therefore, adopting a proactive approach to installation and ongoing maintenance can significantly enhance the reliability and effectiveness of refrigeration systems, ultimately extending their operational lifespan and reducing the total cost of ownership.