Choosing the right Refrigeration Access Valve can significantly impact system efficiency. Industry expert John Smith emphasizes, "Optimal access valves are crucial for maintaining refrigerant flow and system performance." His insights highlight the importance of proper selection.

Refrigeration Access Valves come in various types, and each serves a unique function. For example, some valves allow easy charging, while others enable safe refrigerant recovery. Understanding these differences is vital. A misplaced choice can lead to leaks or inefficient operation.

Additionally, it's essential to consider material compatibility. Some valves may not withstand certain refrigerants, leading to premature failure. Take the time to assess all options carefully. A wrong selection may seem minor but can have lasting effects on performance and maintenance costs.

Refrigeration access valves are essential in any cooling system. They provide access points for technicians to check pressure, add refrigerant, or perform maintenance. Understanding how these valves work is crucial for any professional in the HVAC field. When installed correctly, they can enhance the efficiency and lifespan of refrigeration systems.

The importance of choosing the right access valve cannot be overlooked. Proper selection can prevent leaks and ensure accurate measurements. A well-fitting valve allows for easier service, reducing downtime. However, not all systems are the same. There may be challenges when adapting a standard valve to a unique system. It's vital to consider factors like size, compatibility, and application. Sometimes, this may lead to trial and error, which can be time-consuming.

Understanding the basics of these valves helps navigate common pitfalls. Familiarity with various types can improve decision-making. Some valves may be more prone to malfunction than others. Regular inspections should never be neglected. They are the key to maintaining system integrity. Small issues, if ignored, can snowball into larger problems.

| Feature | Description | Considerations |

|---|---|---|

| Type of Valve | Different types (e.g., Schrader, ball valves) for diverse applications. | Choose based on system requirements and refrigerant type. |

| Size | Common sizes include 1/4", 3/8", and 1/2" depending on the system. | Match valve size to the service port size for optimal fit. |

| Material | Typically brass or aluminum, impacting durability and corrosion resistance. | Consider working conditions and exposure to refrigerants. |

| Pressure Rating | Rated for high, medium, or low pressure applications. | Ensure the valve can handle the system's pressure requirements. |

| Ease of Access | Design considerations for serviceability in tight spaces. | Choose valves that offer quick connection/disconnection features. |

Refrigeration access valves are essential for maintaining and servicing refrigeration systems. They allow technicians to monitor pressures and recharge refrigerants. There are mainly two types of valves: manual and automatic access valves. Manual valves require hand tools for operation, while automatic valves function without direct intervention. Each type serves specific applications in the field.

Research indicates that 80% of refrigeration issues stem from improper servicing. This highlights the importance of choosing the correct valve type. Manual valves might be cheaper, but they can lead to leaks if not properly sealed. On the other hand, automatic valves offer convenience, yet they can be more expensive. Both types need proper installation and maintenance to function effectively.

It’s vital to consider your system's requirements. An improper valve choice could result in energy inefficiencies or even costly breakdowns. Some reports suggest that up to 30% of refrigerant loss is due to faulty valves. Ensure you assess your needs carefully, as the effect of a wrong choice can be quite significant. Choose wisely to avoid regret later.

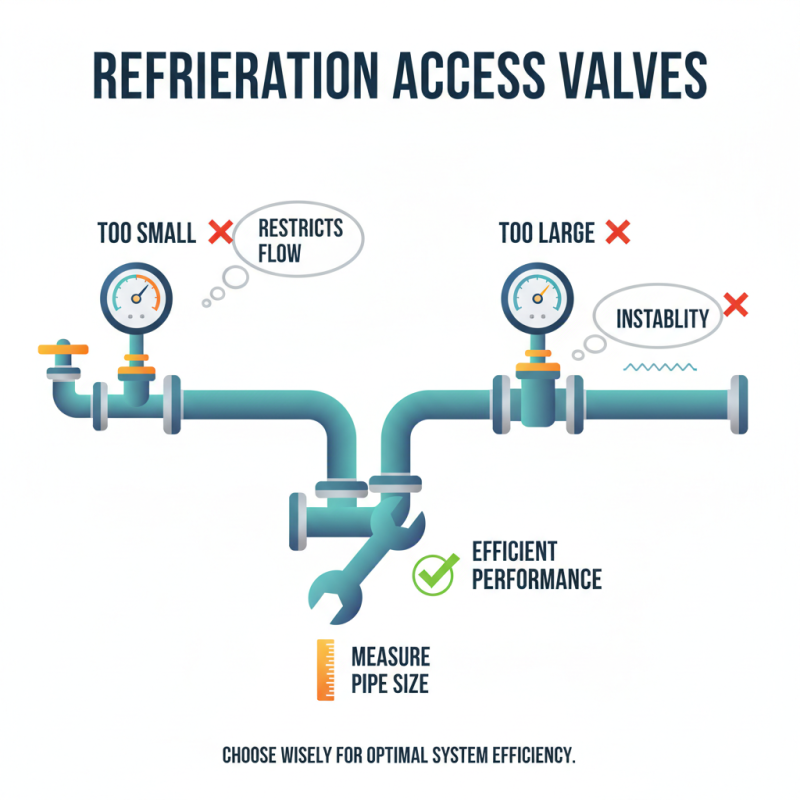

Choosing the right refrigeration access valve is crucial for efficient system performance. There are several factors to consider when making this decision. First, the size of the valve matters. A valve that is too small restricts flow. Conversely, a valve that's too large can create instability. Measure the system’s piping and choose accordingly.

Material is also important. Stainless steel and brass are common choices. Each material has its strengths and weaknesses. Stainless steel offers durability, while brass is cost-effective. Think about the environment too. Will the valve be exposed to harsh conditions? Reflect on how this might impact your choice.

Finally, consider installation. Some valves are easier to install than others. A complicated installation can lead to errors. Don't rush this stage; it's essential for long-term reliability. Take time to evaluate all options. An informed decision will save you from potential issues later on.

Choosing the right refrigeration access valve involves a keen understanding of valve specifications. Pay attention to key factors such as size, pressure rating, and material. These specifications heavily influence performance. For instance, valves made of brass can withstand higher pressures, typically up to 600 psi. In contrast, stainless steel valves may be better suited for corrosive environments.

Performance metrics are essential. The flow coefficient (Cv) indicates how efficiently a valve can transmit fluid. A study showed that valves with a higher Cv provide better flow rates, which can enhance system efficiency by up to 15%. Additionally, the temperature rating should match the operational conditions. Valves rated for low-temperature use may be necessary in certain refrigeration applications.

However, it’s important to remember that valve selection is not foolproof. Overlooking compatibility with the refrigerant type can lead to leaks or system failure. Regular maintenance and inspections can help identify potential issues early. Some valves can become less effective over time, which may go unnoticed until it impacts performance. Understanding these nuances can lead to more informed choices and better overall efficiency in refrigeration systems.

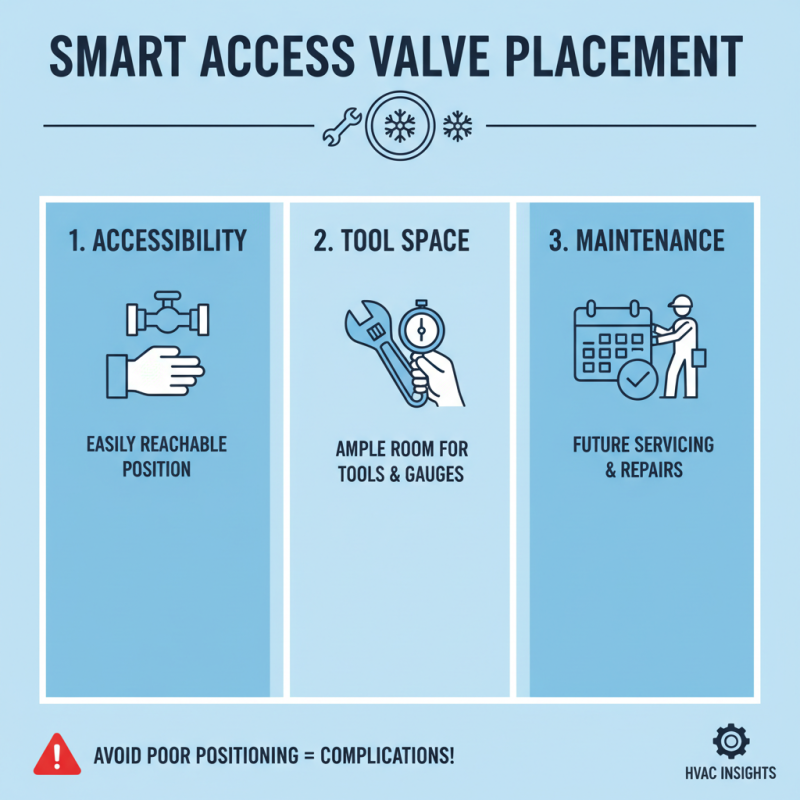

When installing an access valve in a refrigeration system, consider the location carefully. Place it where it is easy to reach. A poorly positioned valve can lead to complications. Ensure you have enough space for tools and for future maintenance.

Tips: Always use the right wrench for securing connections. A loose valve can cause leaks. Regularly inspect the valve for signs of wear or damage. Small issues can escalate quickly.

Routine maintenance is essential. Check for ice buildup around the valve. This can indicate improper functioning. In addition, purging the system before working on refrigerants can prevent contamination. Remember to follow safety protocols during this process.

Select your acess valves wisely. Not all valves fit every system perfectly. A mismatch can lead to inefficiency. Keep your equipment in mind and prioritize compatibility.