The selection of the correct Copper Filter Drier is a critical aspect of maintaining an efficient and reliable HVAC system. According to recent industry reports from the Air Conditioning, Heating, and Refrigeration Institute (AHRI), improper filtration and moisture management can lead to up to 30% of energy losses in HVAC systems. This highlights the importance of strategically choosing the right components, as a well-functioning Copper Filter Drier not only enhances system efficiency but also prolongs equipment life.

Industry expert Dr. Richard Halvorson, a leading figure in HVAC system optimization, emphasizes the necessity of proper filtration, stating, "Selecting the right Copper Filter Drier is imperative for ensuring optimal performance and longevity of HVAC systems." This underscores the fact that an appropriate Copper Filter Drier can significantly mitigate the risks associated with moisture and contaminants, preventing compressor damage and refrigerant issues. As HVAC technology evolves, understanding the specifications and applications of various filter driers becomes essential for both professionals and end-users seeking to enhance the sustainability of their systems.

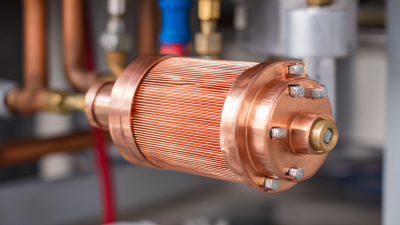

Copper filter driers play a crucial role in the efficiency and longevity of HVAC systems. They function by removing moisture and contaminants from refrigerants, preventing potential issues such as corrosion and compressor failure. According to the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), moisture can lead to significant performance degradation in HVAC systems, with studies indicating that even small amounts of water vapor can reduce system efficiency by as much as 15%. This highlights the importance of selecting an appropriate filter drier that can effectively manage these contaminants.

Choosing the right copper filter drier involves understanding its capacity and the specific requirements of the HVAC system. Filter driers are available in various sizes and filtration capabilities, which are essential factors in ensuring the system operates at optimal performance. A report from the International Journal of Refrigeration emphasizes that using a filter drier with the correct capacity can improve refrigerant flow and enhance system reliability, reducing maintenance costs by up to 30%. It is also important to consider the operating conditions, such as the type of refrigerant used and the temperature range, to ensure the selected filter drier is compatible and effective.

When selecting a copper filter drier for your HVAC system, it’s essential to consider several key factors that can significantly impact the performance and longevity of your equipment. One critical factor is the refrigerant compatibility. According to the Air Conditioning Contractors of America (ACCA), different refrigerants have distinct chemical properties, which can interact variably with filter materials. Therefore, ensuring the filter drier is designed for use with the specific refrigerant in your system—whether it’s R-410A, R-22, or another—will help maintain system efficiency and prevent potential failures.

Another important consideration is the filter drier's capacity and moisture-holding ability. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) notes that moisture in HVAC systems can lead to ice formation, corrosion, and operational inefficiencies. Selecting a filter drier that can adequately handle the moisture load according to the size and type of your HVAC system is crucial. Proper specification of the filter drier’s micron rating is also essential; research shows that a rating of 5 microns or less can effectively trap debris and contaminants, thus promoting system cleanliness and extending the life of both the filter drier and the HVAC unit.

Lastly, ensure that the filter drier supports the system's flow requirements. The National Association of Home Builders (NAHB) recommends checking the manufacturer’s specifications for flow rates, as improper flow can lead to inadequate system performance. A filter drier that meets the recommended flow rates will support efficient refrigerant circulation, ultimately leading to energy savings and optimal system operation. These considerations are vital for ensuring you choose the right copper filter drier that enhances the efficiency and durability of your HVAC system.

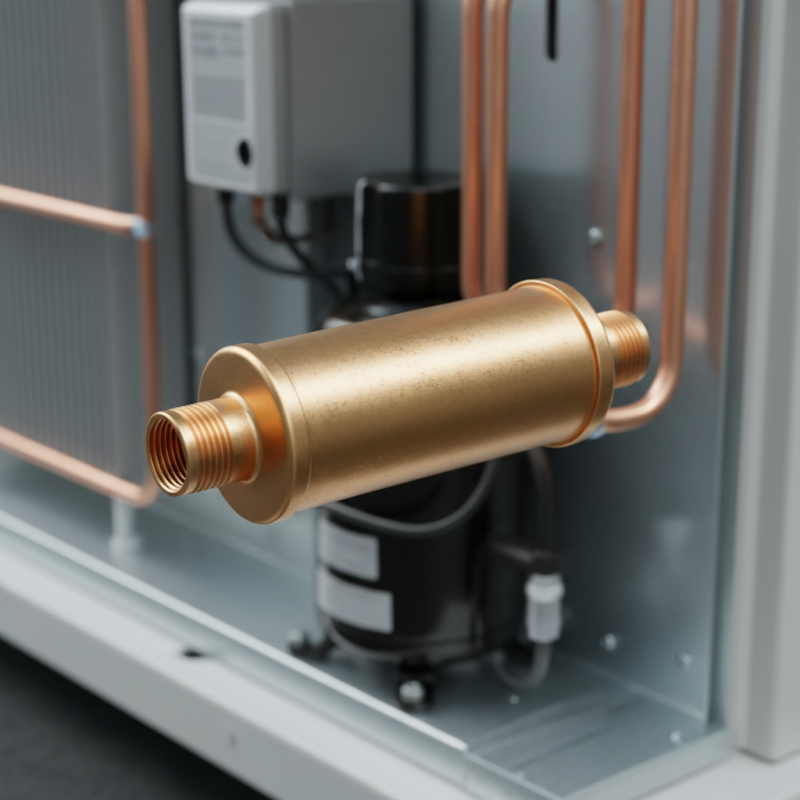

When selecting a copper filter drier for your HVAC system, it is essential to understand the various types available and their specific applications. Two primary types of copper filter driers are liquid line driers and suction line driers. Liquid line driers are typically placed on the liquid refrigerant line and are designed to remove moisture and particles before the refrigerant enters the expansion device. Their primary function is to ensure that the refrigerant remains free of contaminants, which can cause system inefficiencies or failures.

On the other hand, suction line driers are installed on the suction line, which carries refrigerant vapor back to the compressor. These driers are especially effective at absorbing excess moisture that can result from system leaks or improper maintenance. Understanding the differences between these types of driers helps HVAC professionals determine the best choice for a specific application based on factors such as system design, refrigerant type, and installation location. Proper selection and installation of the right copper filter drier not only enhance the efficiency of the HVAC system but also prolong its lifespan.

When selecting and installing a copper filter drier for your HVAC system, attention to detail during installation can significantly impact performance and longevity. A copper filter drier plays a crucial role in removing moisture and contaminants from refrigerants, thereby preventing system failures and enhancing efficiency. According to industry reports, improper installation of these components can result in refrigerant contamination and a potential reduction in system efficiency by up to 20%. Thus, ensuring a precise installation process is paramount.

One key installation tip is to properly site the drier within the refrigerant flow path. Ideally, the filter drier should be located as close to the service ports as possible to minimize moisture ingress. To guarantee optimal performance, it’s vital to use appropriate connections and ensure that the drier is installed in a vertical position when possible, as this allows for better liquid flow and reduces the risk of liquid refrigerant carrying contaminants directly into the compressor. Moreover, before installation, it is advisable to clean the drier and HVAC system lines thoroughly to remove any debris or moisture, as residual impurities can diminish the lifespan of the filter drier, potentially leading to significant repair costs.

Finally, regular maintenance and monitoring of the filter drier’s condition are essential. Industry guidelines recommend checking and replacing filter driers every five years, or sooner if the HVAC system shows signs of wear or reduced efficiency. Implementing these installation tips and maintenance practices can help maximize the performance of copper filter driers in HVAC systems, ultimately leading to improved reliability and energy savings.

When it comes to maintaining HVAC systems, the copper filter drier plays a pivotal role in ensuring optimal performance. Regular maintenance of these components not only enhances their longevity but also improves overall system efficiency. One essential best practice is to regularly inspect the filter drier for any signs of wear or contamination. Keeping the filter free from debris and moisture can prevent unnecessary repairs and extend its lifespan.

Tips: Schedule routine maintenance checks at least twice a year to keep an eye on the filter drier's condition. During these inspections, replace the filter media if it shows signs of clogging, as this can restrict airflow and lead to further complications.

Another important aspect to consider is the installation of the filter drier. Proper installation ensures that the unit functions effectively and reduces the chances of leaks or damage. Following the manufacturer's guidelines for sizing and positioning is crucial for optimal performance. Additionally, ensuring that the system is properly vacuumed and charged after installation can save you from future maintenance headaches.

Tips: Keep track of your maintenance schedule and replace the filter drier during significant system overhauls or when refrigerant levels are adjusted. This proactive approach will help you maintain a robust HVAC system.