Choosing the right Air Dryer Filter can seem daunting. With various options available, making an informed decision is crucial. Expert John Miller, a prominent figure in the air filtration sector, once stated, “Selecting an air dryer filter is essential for maintaining system efficiency.” Such wisdom underscores the importance of understanding your specific needs.

An Air Dryer Filter is vital for removing moisture and contaminants. For instance, if you're operating in a humid environment, selecting the right filter can make a difference. It's not just about function; it's about longevity and performance. Many filters claim to do it all, but that's not always true. Some filters might struggle under heavy loads or specific conditions.

Reflect on your requirements. Do you need a filter that can handle heavy particulate? Or are you mainly concerned with moisture? The nuances in your choice can lead to costly mistakes or efficiency issues. A well-chosen Air Dryer Filter enhances performance and safeguards your equipment. However, neglecting this choice might lead to short-term savings but long-term headaches. Always remember, the right filter can improve your system significantly.

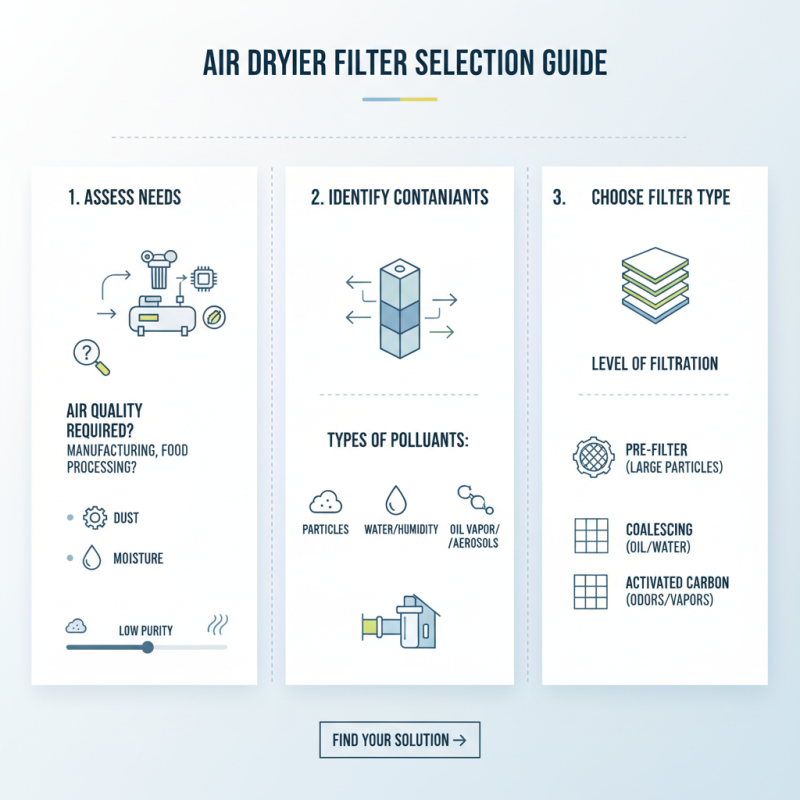

Air dryer filters play a critical role in your compressed air system. They remove moisture, particulate matter, and oil, which can lead to equipment failure and product contamination. According to industry reports, nearly 70% of compressed air system issues are related to contamination. This makes understanding filter types essential.

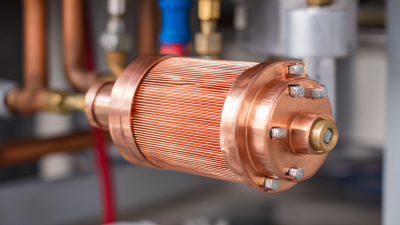

Desiccant filters are popular for their efficiency. They can achieve a moisture dew point as low as -40°F. However, they require regular maintenance to replace the desiccant material. On the other hand, coalescing filters excel at removing oil aerosols, with efficiency ratings exceeding 99%. These filters can protect downstream equipment but may also become saturated and need replacement.

Many users overlook the importance of sizing their filters correctly. A filter that is too small can cause pressure drops. Conversely, an oversized filter may lead to unnecessary costs and reduced efficiency. Understanding your specific air quality needs can guide you in making the right choice, but it’s a fine balance. Users often face challenges in determining the best filter for unique conditions.

When it comes to air dryer filters, understanding the types available can significantly impact your operations. Common types include particulate filters, coalescing filters, and desiccant filters. Particulate filters are essential for trapping solid particles, achieving efficiencies of around 99.9% for particles of 0.3 microns. They are often the first line of defense in air filtration.

Coalescing filters work slightly differently. They capture water and oil aerosols by forcing air through a fibrous material. According to industry reports, these filters can remove 99.99% of liquid contaminants. This type is particularly beneficial in compressed air applications where moisture control is vital. Desiccant dryers, on the other hand, absorb moisture from compressed air. They are typically used in situations requiring low dew points, reaching levels as low as -40°F (-40°C).

Choosing the correct filter is crucial. Not all applications demand the same level of filtration. It's common for operators to overlook the specific needs of their systems. Misunderstanding filtration requirements can lead to inefficient operation. This can increase wear on equipment and reduce overall efficiency. Investing time to assess your unique requirements will yield long-term benefits.

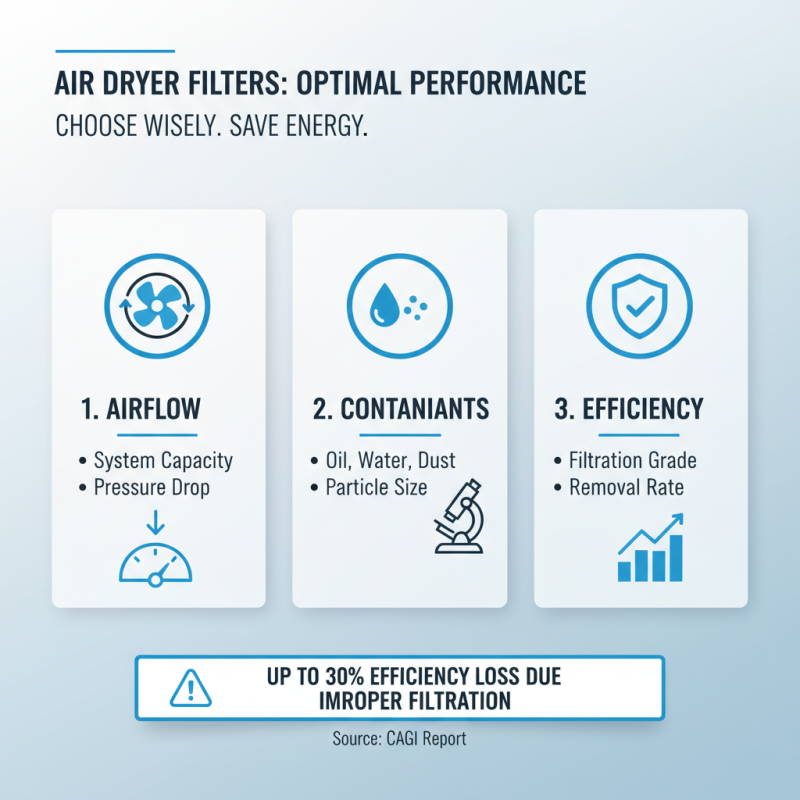

Choosing the right air dryer filter is crucial for optimal performance. Professionals often cite airflow, contaminant type, and filter efficiency as key factors. According to a report by the Compressed Air and Gas Institute (CAGI), compressed air systems can lose 20-30% efficiency due to improper filtration. This is significant.

Understanding the airflow needs of your system is essential. If the airflow is inadequate, it can lead to water and oil carryover. Moreover, selecting the right contaminants to filter is vital. For instance, removing oil aerosols may require a coalescing filter, while particulates might need a mechanical filter. In some cases, an improperly selected filter can cause damage to downstream components.

Efficiency ratings matter too. A filter with 99.9% efficiency will do a much better job than one with a lower rating. However, it's essential to consider maintenance. A higher efficiency filter may need frequent replacement, leading to unplanned costs. Reflect on your specific operational needs and budget. Not every application requires the highest-performing filter. Balancing cost and performance is key for many industries.

Choosing an air dryer filter begins with understanding your specific needs. Air quality is vital in various applications, from manufacturing to food processing. Contaminants like dust and moisture can jeopardize processes and products. Assess the level of purity required in your environment. Think about how clean your air should be. This assessment is often overlooked.

Flow rate is just as important. Different tasks demand different flow rates. A filter that works well for one application may fail in another. Too low a flow rate can slow down production. Too high can let dirt through. It’s crucial to find a balance that suits your operation. Measure your needs accurately. Remember that making a wrong choice can cause issues down the line.

Consider space constraints as well. Filters vary in size and installation requirements. The space available might limit your options. Don't forget maintenance needs too. Filters need regular checks. Ignoring this can lead to reduced efficiency. Finding the right filter is a mix of analysis and trial and error. Making decisions without proper assessment can lead to future regrets. Take the time to reflect on what works best for you.

Choosing the right air dryer filter is crucial for optimal performance.

Regular maintenance can significantly improve the lifespan of these filters.

According to industry reports, 30% of air system failures are associated with improper filtration practices.

Thus, monitoring and replacing your filters as needed can reduce downtime and repair costs.

Inspect filters frequently. Visual checks can reveal dirt accumulation or damage.

If you notice visible contaminants, it may be time to replace the filter.

Many experts recommend changing air dryer filters every 6 to 12 months.

However, the actual interval varies by usage. Some facilities might require more frequent replacements due to higher airborne contaminants.

Consider also the maintenance procedures in place.

Neglecting these practices can lead to compressed air quality issues.

Airborne moisture can cause corrosion in systems.

A small leak or failure in the filtration unit often results in significant performance drops.

Pay attention to these details. Optimize your system by ensuring your filters are always in good condition.