In the ever-evolving world of refrigeration systems, choosing the right Refrigeration Filter Drier is crucial for optimizing performance and longevity. According to a recent industry report by the Global Refrigeration Council, approximately 30% of refrigeration-related failures can be traced back to improper filtration and moisture control. This alarming statistic underscores the importance of selecting the appropriate filter drier to ensure the efficiency and reliability of refrigeration systems.

Expert in refrigeration technology, Dr. Emily Johnson, emphasizes the role of Refrigeration Filter Driers by stating, "The correct selection and installation of a filter drier can significantly enhance the operational efficiency of refrigeration systems, directly impacting energy consumption and system longevity." As the demand for energy-efficient solutions increases, understanding the varying specifications and capabilities of filter driers becomes imperative for both installers and end-users.

With a multitude of options available in the market, this guide aims to provide essential insights into choosing the right Refrigeration Filter Drier tailored to specific system requirements. By delving into key factors such as refrigerant type, system capacity, and environmental conditions, stakeholders can make informed decisions that not only preserve the integrity of their equipment but also contribute to sustainable practices in the refrigeration industry.

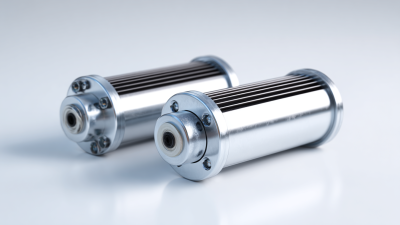

Refrigeration filter driers play a crucial role in the overall efficiency and longevity of refrigeration systems. Essentially, these components serve two primary functions: filtering out contaminants and absorbing moisture. According to a report by the Air Conditioning, Heating, and Refrigeration Institute (AHRI), contaminants such as dirt, metal shavings, and other particulates can significantly impact system performance. These contaminants typically originate from the wear and tear of system components or can enter during maintenance and installation. Therefore, utilizing an effective filter drier helps maintain system cleanliness, which is vital for optimal operation and efficiency.

Moreover, moisture removal is equally important. Excess moisture in the refrigerant cycle can lead to the formation of acids and other corrosive agents, which can damage compressor components. A study by the International Institute of Refrigeration (IIR) estimates that nearly 30% of refrigeration system failures could be attributed to moisture contamination. By employing a filter drier with the appropriate desiccant material, operators can prevent such issues, ensuring that the refrigerant remains free of moisture and the overall system operates smoothly for a prolonged period. Thus, understanding the underlying functions of refrigeration filter driers is essential for selecting the right component for specific refrigeration applications.

When selecting the right refrigeration filter drier for your system, understanding the different types available and their specific applications is crucial. There are primarily two types of filter driers: liquid line filter driers and suction line filter driers. Liquid line filter driers are utilized in AC and refrigeration systems to remove moisture and contaminants from the refrigerant before it enters the evaporator. They are essential in preventing system corrosion and increasing the longevity of refrigeration components. In contrast, suction line filter driers serve to protect the compressor by filtering out debris and retaining liquid refrigerant, which is particularly important in systems where liquid refrigerant might return to the compressor.

According to industry reports, approximately 30% of refrigeration system failures can be attributed to improper filtration and moisture presence. Thus, selecting the appropriate type of filter drier based on your application is vital for maintaining system efficiency.

Tip: Always consider the compatibility of the filter drier with your refrigerant type and system design. For example, systems using R-410A require filter driers specifically rated for this higher pressure refrigerant. Additionally, consult the manufacturer specifications for flow rates and pressure drops to ensure optimal performance within your system.

| Type of Filter Drier | Application | Refrigerants Compatibility | Operating Temperature Range | Key Features |

|---|---|---|---|---|

| Short Carbon Filter Drier | Residential AC Units | R-410A, R-22 | -10°C to 55°C | Compact design, good moisture absorption |

| Large Capacity Filter Drier | Commercial Refrigeration | R-134A, R-404A | -20°C to 65°C | High capacity, robust construction |

| Spin-on Filter Drier | Automotive AC Systems | R-134A, R-1234yf | -5°C to 70°C | Easy installation, portable |

| Core Type Filter Drier | Commercial HVAC | R-410A, R-407C | -15°C to 50°C | Refrigerant filter, easy maintenance |

When choosing the right refrigeration filter drier for your system, there are several key factors to consider to ensure optimal performance and efficiency. Firstly, the compatibility of the filter drier with the refrigerant type being used is crucial. Some filter driers are designed to work specifically with certain refrigerants, and using the wrong type can lead to system failure or reduced efficiency. Therefore, verifying the specifications of both the filter drier and the refrigerant is an essential first step in the selection process.

Additionally, the size and capacity of the filter drier should match the requirements of your refrigeration system. A drier that's too small may not effectively remove moisture and contaminants, while an oversized drier can lead to other issues, such as pressure drops or inefficient operation. Evaluating the flow rates and system requirements will aid in selecting the appropriate size. Finally, consider the construction materials and the filter drier’s ability to handle varying temperatures and pressures over time, which can significantly influence the durability and performance of the unit. By taking these factors into account, you can ensure a better choice for your refrigeration needs.

The following bar chart showcases key factors to consider when selecting a refrigeration filter drier, measured by their importance on a scale from 1 to 10.

When installing a refrigeration filter drier, it is important to ensure that the unit is compatible with your refrigerant type and system requirements. Begin by selecting a filter drier that matches the capacity and specifications of your refrigeration system. Incorrect sizing can lead to inefficiencies, reduced performance, and potential damage to the system. Before installation, carefully read the manufacturer's specifications and guidelines to verify compatibility with the refrigerant and oil type you are using.

During installation, ensure that the filter drier is placed in the correct orientation as indicated by the arrow on its casing, which directs the flow of refrigerant. Typically, the filter drier should be installed in the liquid line, preferably after the receiver in commercial systems. It is essential to properly braze the connections to avoid leaks. Using a nitrogen purge during brazing can prevent oxidation inside the drier, preserving its efficacy.

Additionally, verify all connections are tight, and perform a leak test before recharging the system to confirm that there are no issues that could compromise the operation of the refrigeration system. Following these installation guidelines will maximize the lifespan and functionality of your refrigeration filter drier.

When it comes to optimizing the performance of your refrigeration system, the upkeep of the filter drier is paramount. Regular maintenance can significantly prolong the lifespan of your refrigeration equipment and ensure efficient operation. A key aspect of care involves routine inspections; checking for signs of wear, moisture accumulation, and blockages should be an integral part of your maintenance schedule. Implementing a preventive maintenance plan that includes visual inspections and pressure tests can help identify potential issues before they escalate, allowing for timely interventions.

Additionally, understanding when to replace the filter drier is crucial for maintaining system efficiency. Factors such as operation hours, environment, and previous maintenance history play a significant role in determining replacement frequency. Keeping an eye on the performance metrics of your refrigeration system can provide valuable insights; if you notice a drop in efficiency or unusual system pressures, it may indicate that the filter drier needs replacement. Adhering to the manufacturer's guidelines and utilizing best practices for care and replacement will ensure that your refrigeration system operates effectively, minimizing the risk of costly breakdowns and energy waste.