In today's industrial landscape, efficiency and quality are paramount. Many manufacturers are turning to Filter Dryers for their capabilities. Paul Anderson, a renowned expert in the field, once stated, “Filter Dryers combine filtration and drying, providing a compact solution for industries.” His insight emphasizes the practicality of these devices.

Filter Dryers not only streamline processes but also enhance product purity. They offer a seamless transition from solid-liquid separation to efficient drying. Businesses can reduce production time and improve yield significantly. However, some companies may hesitate to adopt this technology. They often wonder if the investment is truly worthwhile.

Adopting a Filter Dryer requires careful consideration. While the benefits are clear, not every facility may be ideal for this solution. Engineers must evaluate the specific needs of their processes. Ultimately, the choice to use a Filter Dryer demands thorough reflection on both operational goals and financial implications.

Filter dryers play a crucial role in various industrial processes. They combine filtration and drying, streamlining production. A study by the Global Market Insights suggests a compound annual growth rate (CAGR) of 5.2% for filter dryer demand over the next five years. This indicates a robust trend in adopting this technology.

One significant benefit is increased efficiency. Filter dryers minimize processing time. They eliminate additional handling steps involved in separate filtration and drying processes. According to recent reports, companies utilizing filter dryers can reduce operational costs by up to 30%. This is a notable advantage in a highly competitive environment.

Tip: Regular maintenance of filter dryers enhances their lifespan. Preventive measures can be cost-effective.

While filter dryers offer many benefits, there are challenges. Understanding the specific needs of a process is essential. Not every filter dryer suits every application. A detailed assessment can prevent unnecessary investments.

Tip: Involve team members in the selection process. Their insights can lead to better-informed decisions.

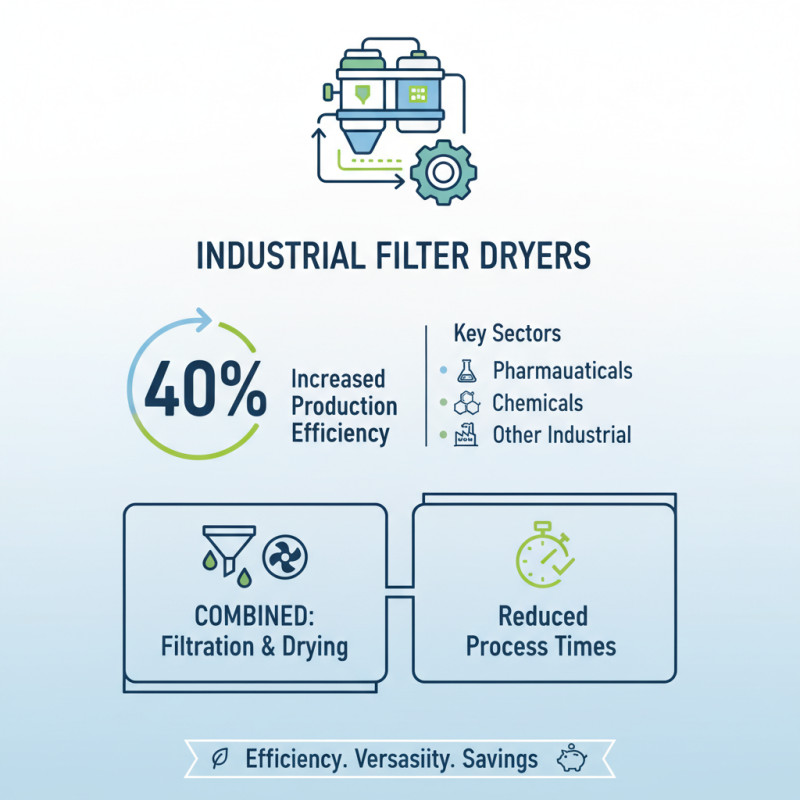

Filter dryers are increasingly favored in industrial applications due to their efficiency and versatility. These devices combine filtration and drying in a single unit. This integration can reduce process times significantly. According to a recent industry report, filter dryers can improve production efficiency by up to 40%. This is particularly beneficial in sectors like pharmaceuticals and chemicals.

One of the defining features of filter dryers is their ability to handle various materials. They accommodate slurries, powders, and granules. This flexibility allows manufacturers to adapt to changing production needs without extensive equipment modifications. Additionally, the closed system design minimizes exposure to air, enhancing product quality and reducing contamination risks. However, some users have reported challenges in maintenance due to the complexity of the systems.

Despite their advantages, it’s important to acknowledge the limitations. The initial investment for filter dryers can be higher compared to traditional methods. Ongoing maintenance and operator training may also be required. A careful analysis of these factors is essential to ensure the right choice, balancing operational needs with long-term costs. Implementing filter dryers can lead to substantial gains, but a thorough evaluation is key.

Filter dryers are gaining traction in various industries due to their efficiency and versatility. They excel in pharmaceutical applications, where stringent quality standards are critical. A recent report from the Pharmaceutical Manufacturers Association indicates that the need for superior drying technology is on the rise, with a projected market growth of 5% annually until 2025. Filter dryers optimize the removal of solvents and moisture while ensuring product integrity.

In the chemical industry, filter dryers address the challenge of handling fine powders and crystals. According to a study by the Society of Chemical Engineers, almost 70% of chemical producers report issues with inconsistent drying processes. Filter dryers provide improved consistency and reduce the risk of contamination in sensitive materials. The ability to automate these processes can enhance operational efficiency, but not all installations are flawless. Some facilities report challenges with maintenance and adaptability to new materials.

For food processing, filter dryers offer significant advantages. They help reduce the drying time and enhance product shelf life. A report by the Food Technology Association highlights that the demand for efficient drying methods in this sector has increased by 6% over the last few years. However, some processors find it difficult to achieve the right moisture levels, leading to variability in final products. This realization calls for ongoing evaluation of technology and processes to ensure that filter dryers meet the industry's evolving needs.

When analyzing the cost-effectiveness of filter dryers, one must consider various key performance metrics. These include energy consumption, maintenance costs, and overall efficiency. Filter dryers can provide a more efficient drying process compared to traditional methods. They often reduce drying time significantly, leading to higher throughput in industrial applications.

However, the initial investment for filter dryers can be high. Companies may hesitate due to this upfront cost. Yet, the long-term savings in energy and reduced labor costs can make filter dryers a smart choice. Additionally, the lower environmental impact is becoming increasingly important for many businesses. These systems can improve resource utilization.

Yet, not all filter dryers are created equal. The effectiveness can vary based on the specific application and material being processed. Regular maintenance is essential to keep them running efficiently. A poorly maintained unit can lead to unexpected downtime and increased costs. Evaluating these factors is crucial before making a final decision. It's essential to weigh both the pros and the cons carefully.

The demand for filter dryers in industrial sectors is on the rise. According to a recent report, adoption rates have surged by 25% over the last five years. Industries like pharmaceuticals and chemicals lead this trend. Their need for efficient and cost-effective drying solutions drives this growth.

Filter dryers offer key advantages. They reduce processing times significantly. Companies report a decrease in energy consumption by up to 30%. However, many organizations still rely on traditional methods. Transitioning to new technologies can be challenging. It requires a cultural shift within teams.

Future growth looks promising. Analysts predict that filter dryer technologies will expand at a compound annual growth rate of 8% over the next decade. Yet, some manufacturers face hurdles. Knowledge gaps and initial costs can impede adoption. Organizations need to invest in training and change management to realize benefits fully. This evolution in industrial processes poses both opportunities and challenges.