In the world of HVAC systems, ensuring optimal performance is crucial for energy efficiency and longevity. One key component that plays a vital role in maintaining system functionality is the Liquid Line Filter Drier. This essential device not only filters out impurities from the refrigerant but also removes moisture, safeguarding your system from potential damage. However, sourcing the right Liquid Line Filter Drier can significantly impact your system's efficiency and reliability. In this blog, we will explore the seven best strategies for sourcing Liquid Line Filter Drier, helping you make informed decisions for optimal performance. By understanding the various aspects of these filters—from compatibility with your system to selecting the most reliable suppliers—you can enhance your HVAC operations and prolong the life of your investment. Let's dive into the best practices that can guide you in this essential aspect of HVAC maintenance.

Liquid line filter driers play a crucial role in HVAC systems by ensuring that contaminants do not compromise system performance. These devices effectively collect and eliminate solid particles, liquid moisture, and aerosol contaminants from the refrigerant before it enters critical components like the compressor. Failing to maintain the filter driers can lead to severe issues, including compressor burnout due to high condensing pressures or refrigerant floodback. Thus, routine checks and maintenance of these filters are essential to ensure operational efficiency and prolong the lifespan of HVAC systems.

As regulations around refrigerants evolve, particularly with the phaseout of R-22, understanding the importance of liquid line filter driers becomes even more vital. Technicians must also pay attention to proper nitrogen purging to prevent system headaches in the long run. By integrating best practices for maintenance and regularly troubleshooting filter driers for potential restrictions or damages, HVAC contractors can enhance system reliability, satisfy customer needs, and keep pace with changing industry standards. Investing time in these strategies is pivotal for optimal performance and compliance with current regulations.

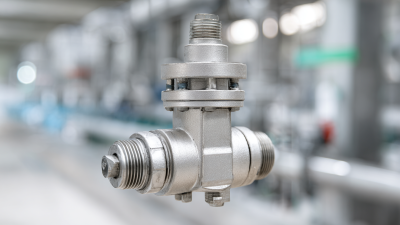

When sourcing liquid line filter driers for optimal performance, several key features must be considered to ensure efficiency and reliability in HVAC systems. One critical factor is the desiccant material; the most effective driers utilize a high-quality molecular sieve that can absorb moisture and contaminants effectively, preventing them from circulating in the refrigerant system. According to industry reports, utilizing the right desiccant can enhance system reliability by up to 30%, significantly extending the lifespan of the components involved.

Additionally, the size and flow rate of the filter drier are crucial. It’s essential to match the drier's capacity to the specific cooling system to prevent pressure drops that can lead to system inefficiency. A study from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that mismatched sizing can decrease system efficiency by as much as 15%.

**Tip:** Always measure the refrigerant flow rate accurately before selecting a filter drier to ensure optimal compatibility.

Another feature to consider is the filter drier's construction material. High-quality aluminum or steel housing can provide better durability and resistance to corrosion compared to plastic alternatives. Filters constructed with robust materials can withstand harsh operating conditions, leading to improved performance and lower maintenance costs over time.

**Tip:** Look for filter driers with a robust warranty, as manufacturers that stand behind their products often deliver better long-term value.

When sourcing a liquid line filter drier, selecting the right manufacturer is crucial for ensuring optimal performance and reliability. Top brands like Parker Hannifin, Sporlan, and Emerson have built a reputation for producing high-quality filter driers that cater to a variety of applications. These manufacturers focus on innovative designs that enhance filtration efficiency and moisture absorption, which are vital for the longevity of refrigeration and air conditioning systems. When choosing a brand, consider their industry experience and track record for reliability.

In addition to well-known manufacturers, exploring niche companies that specialize in filter driers can uncover hidden gems. Brands like Castrol and Danfoss are recognized for their commitment to quality and customer satisfaction. These companies often offer tailored solutions and technical support, which can be beneficial for unique requirements. Additionally, looking into local manufacturers can provide quicker access to products and potentially better pricing, along with personalized service. Always ensure that the selected brands meet industry standards and have positive reviews from other users to guarantee performance and reliability.

When sourcing liquid line filter driers, it’s essential to prioritize both quality and cost efficiency to ensure optimal performance. In today's complex global supply chain landscape, companies face numerous risks, including supply disruptions and fluctuating material prices. Implementing effective sourcing strategies can mitigate these risks and enhance overall performance.

Tip 1: Engage multiple suppliers to create a competitive sourcing environment. This not only minimizes the risk of supply chain disruptions but also allows you to negotiate better prices and terms. Diversifying your supplier base can lead to improved quality and reliability of the filter driers you procure.

Tip 2: Utilize technology and data analytics to evaluate supplier performance and assess total cost of ownership. By analyzing factors such as delivery timelines, quality metrics, and after-sale support, you can make informed sourcing decisions that align with your company’s performance goals.

By adopting these strategies, organizations can streamline their procurement processes and achieve a balance between quality and cost, ultimately leading to better operational efficiencies.

When sourcing liquid line filter driers, avoiding common pitfalls is crucial for ensuring optimal performance. Many buyers overlook the significance of selecting the right filter drier for their specific application, leading to inefficiencies and increased downtime. It is essential to consider factors such as compatibility with existing systems, refrigerant type, and the environmental conditions in which the unit will operate. Failing to account for these variables can result in poor performance and premature failures.

Another common mistake is neglecting the importance of supplier reliability. Choosing suppliers based on price alone can lead to compromises in quality and service. Instead, businesses should focus on establishing relationships with reputable suppliers who offer warranties and support services. This approach not only ensures access to high-quality products but also fosters trust and collaboration throughout the procurement process. By being mindful of these pitfalls, companies can enhance the longevity and functionality of their filter driers, ultimately leading to improved operational efficiency.

| Strategy | Description | Common Pitfall | Optimal Performance Outcome |

|---|---|---|---|

| Research Supplier Credentials | Verify the experience and certification of suppliers. | Ignoring supplier history can lead to poor quality products. | High reliability and adherence to standards. |

| Quality Assessment | Perform thorough testing of filter driers. | Skipping quality checks may increase failure rates. | Enhanced durability and efficiency. |

| Understand Application Requirements | Match filter drier specifications with system needs. | Buying generic products without compatibility checks. | Optimized performance specific to equipment. |

| Leverage Customer Reviews | Check user feedback and experiences. | Overlooking feedback can result in poor purchases. | Higher customer satisfaction and effective solutions. |

| Bulk Buying Benefits | Consider bulk purchasing for cost-efficiency. | Purchasing quantities without storage considerations. | Reduced cost per unit with adequate supply. |

| Seek Expert Consultation | Engage with industry specialists for advice. | Avoiding expert insights may lead to costly errors. | Informed decisions that minimize risks. |

| Regular Follow-ups | Maintain communication with suppliers. | Neglecting follow-ups can disrupt supply chains. | Sustained performance and timely deliveries. |