In the rapidly evolving HVAC industry, efficiency is critical. The choice of a Refrigeration Filter Drier plays a vital role in system performance. According to the latest market reports, improper filtration contributes to up to 30% of system failures. A suitable filter drier not only enhances cooling but also prolongs equipment life.

Recent studies reveal that over 15% of refrigeration energy waste stems from inadequate filtration. This inefficiency can lead to increased operational costs. Selecting the right Refrigeration Filter Drier can mitigate such risks. Quality products reduce contaminants and moisture, ensuring optimal performance.

However, not all filter driers deliver equal results. Some may not provide adequate moisture removal. This can lead to future complications, such as compressor failure. It's essential for HVAC professionals to choose wisely and consider user reviews alongside performance data. Investing in a reliable Refrigeration Filter Drier is a strategic move for improved efficiency and cost-saving.

Refrigeration filter driers play a crucial role in cooling systems. They help maintain efficiency and prolong equipment life. A well-functioning filter drier can remove moisture and contaminants from refrigerants. According to industry reports, up to 80% of refrigeration failures are linked to improper filtration. This underscores the filter drier's importance in refrigeration systems.

These components are designed to absorb moisture effectively. Moisture can lead to corrosion and ice formation within the system. Experts suggest that even a small amount of water can cause significant damage. Regular inspection and replacement of filter driers can prevent costly repairs. Data shows that systems with neglected filter driers operate at 15-20% less efficiency.

However, not all filter driers are created equal. The quality can vary significantly. Some may not meet industry standards, resulting in subpar performance. It is essential to choose the right type for your system. A poorly chosen filter drier could lead to moisture accumulation. This not only affects performance but can also shorten the lifespan of components. Selecting a good filter drier requires careful consideration.

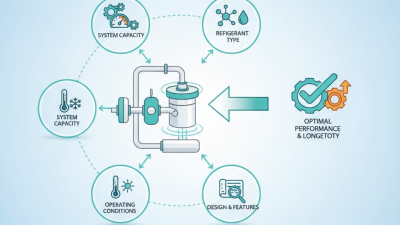

When selecting the best refrigeration filter drier for efficient cooling, key features significantly impact performance. One important aspect is filtration efficiency. A high-quality drier can filter out particulates as small as 5 microns, preventing damage to compressors. According to the Air-Conditioning, Heating, and Refrigeration Institute, systems without effective filtration can face up to 30% reduced efficiency.

Moisture control is another critical feature. Excessive moisture in refrigerants can lead to acid formation, damaging components like compressors. Top-performing driers utilize desiccants capable of absorbing water to levels below 50 parts per million. Industry reports suggest that maintaining low moisture levels can improve system longevity by 20% or more.

Compatibility with various refrigerants should be assessed as well. With the HVAC industry shifting towards low-global warming potential refrigerants, it’s essential for driers to be versatile. Some reports indicate that non-compatibility issues can lead to failures in up to 15% of systems. Thus, choosing a drier that supports modern refrigerants is crucial for efficient cooling and long-term savings. However, not all options perform equally, and choosing the wrong type may result in unexpected costs.

As the demand for efficient cooling systems rises, choosing the right refrigeration filter drier becomes crucial. In 2026, several models stand out in terms of performance and reliability. The cooling efficiency is often influenced by the filter drier's ability to remove moisture and contaminants effectively. Industry reports indicate that a quality filter drier can reduce system failures by up to 30%. This can lead to significant savings in repair costs over time.

Product reviews and technical analyses highlight the importance of adaptive features. Some models now come with advanced filtration technology. These innovations can improve airflow while reducing energy consumption. Yet, not all models meet quality standards. Some might only serve a limited lifespan or require frequent replacements. Users must research thoroughly before their purchase.

Some brands boast a high rate of efficiency, with many driers achieving an efficiency rating above 97%. However, it is worth noting that cost can often lead to compromised quality. Cheaper options may lack durability, ultimately leading to increased maintenance needs. Careful consideration of both price and performance is essential for making the best choice.

When installing refrigeration filter driers, attention to detail is crucial. Ensure that the filter drier is compatible with your system. Incorrect specifications can lead to inefficiencies. Always check the flow direction indicated on the unit. A common mistake is reversing this, causing improper operation.

Maintenance is essential for optimal performance. Regularly inspect the filter drier for signs of clogging or leaks. Clean the system periodically to avoid buildup. Some technicians forget to do this, leading to costly repairs. Replace the filter drier as recommended, usually every few years. Use the right tools for installation and make sure all seals are tight. This prevents contaminants from entering the system.

Failures can often stem from neglect. It’s critical to follow all manufacturer guidelines. The right installation can save time and money later. Document any work done for future reference. This practice aids in troubleshooting and ensures consistency. Even a small oversight can have significant consequences. Always take the time to double-check your work.

Refrigeration filter driers are essential for maintaining efficient cooling systems. However, they can encounter various issues that impact performance. Clogged filters often lead to reduced airflow. Dirty components can cause overheating as well. Regular maintenance is crucial to avoid these problems.

Many users overlook the signs of a malfunctioning filter drier. A strange noise or fluctuating temperatures may indicate a blockage. Ignoring these symptoms can lead to costly repairs. Regularly checking the pressure levels is also important. Low pressure might signal a refrigerant leak or other issues.

Detecting moisture is vital. Moisture in the system can cause corrosion and damage to components. Employing a vacuum pump during installation is a good practice. This helps eliminate moisture before adding refrigerant. Maintenance should also include replacing the filter drier at recommended intervals. Skipping this step can lead to reduced efficiency.