In the realm of HVAC systems, the efficiency of a heat pump is greatly influenced by its components. One critical component is the Heat Pump Filter Drier. Renowned expert Dr. Sarah Thomas states, "A well-functioning filter drier is vital for maintaining energy efficiency in heat pumps." This underscores the importance of selecting the right filter drier for optimal performance.

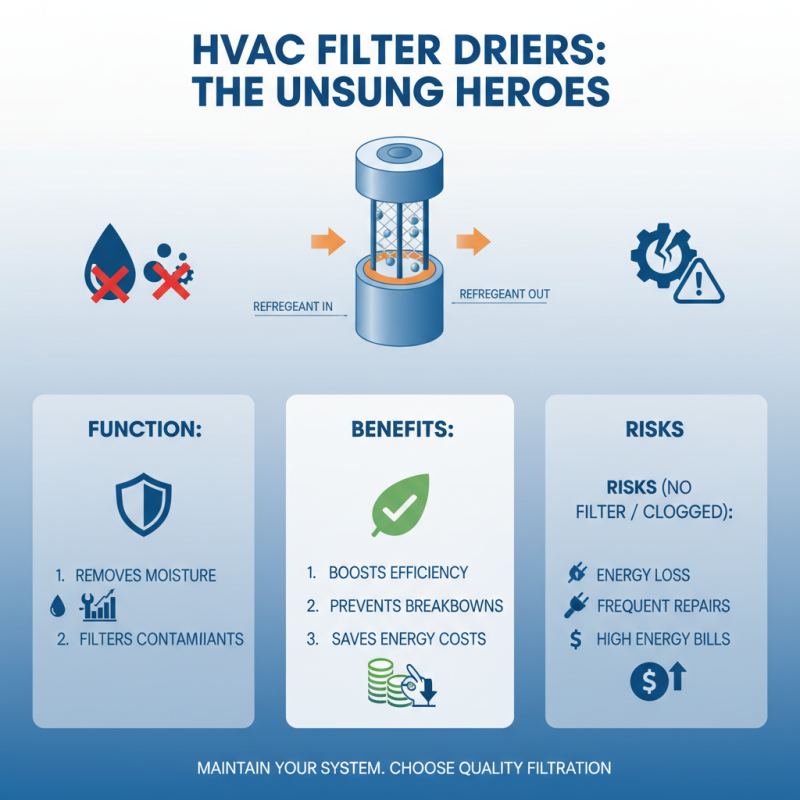

Heat Pump Filter Driers serve as guardians against moisture and contaminants. They ensure the refrigerant circulates freely, helping the system perform efficiently. However, not all filter driers are created equal. Choosing the best one can significantly impact energy use and overall system longevity.

Many users overlook regular maintenance of their filter driers. They may not realize that a neglected filter can lead to increased energy consumption and eventual system failure. Investing time and resources in selecting an appropriate Heat Pump Filter Drier can save you money in the long run. With the right choice, your heat pump can run smoothly and use energy efficiently.

Heat pump filter driers play a crucial role in ensuring the efficiency of heat pump systems. These components help remove moisture, debris, and contaminants from the refrigerant. A clean refrigerant leads to better performance and extended system life. Studies show that moisture can decrease the efficiency of heat pumps by up to 30%. A properly functioning filter drier can help mitigate this issue.

Regular maintenance of filter driers is key. Inspecting the filter drier every six months is a good practice. This can prevent potential clogs that hinder airflow. Remember, a clogged drier can lead to increased energy consumption and higher bills. It might seem tedious, but your energy bills will thank you.

Tips: Always use a filter drier compatible with your heat pump. Incompatible driers can cause efficiency issues. Additionally, consider replacing the drier every five years. This ensures optimal performance and energy efficiency. Address potential issues before they escalate. A little attention can lead to significant energy savings over time.

| Filter Drier Type | Application | Maximum Operating Pressure (psi) | Refrigerant Compatibility | Moisture Removal Capacity (grams) | Weight (lbs) |

|---|---|---|---|---|---|

| Standard Filter Drier | Residential Heat Pumps | 300 | R410A, R22 | 50 | 2.5 |

| Bi-flow Filter Drier | Heat Pump Systems | 400 | R410A, R32 | 75 | 3.0 |

| Liquid Line Filter Drier | Commercial Heat Pumps | 350 | R134A, R404A | 60 | 2.0 |

| Molecular Sieve Filter Drier | Specialty Applications | 500 | R410A, R22, R404A | 90 | 4.0 |

When exploring heat pump filter driers, it is important to understand the different types available. There are three main categories: standard, bi-flow, and liquid line driers. Each serves a distinct purpose and can vastly affect energy efficiency.

Standard filter driers are often used in cooling applications. They remove moisture and contaminants. This helps maintain system efficiency. Bi-flow driers have a unique design. They work in both heating and cooling cycles. This dual functionality maximizes energy use throughout the year. Liquid line driers, on the other hand, are placed in the refrigerant line. They ensure that only clean refrigerant enters the compressor.

Choosing the right type can be tricky. Often, users overlook specific requirements. The system's design and operational conditions matter. A mismatch can lead to reduced efficiency and increased costs. Careful consideration of each type allows for better performance. Investing time in research will pay off in the long run. Understanding these choices is essential for energy-efficient heating and cooling solutions.

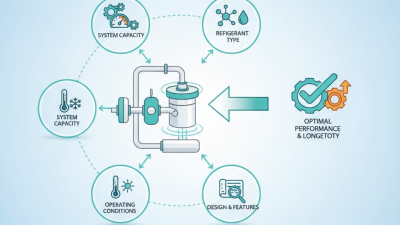

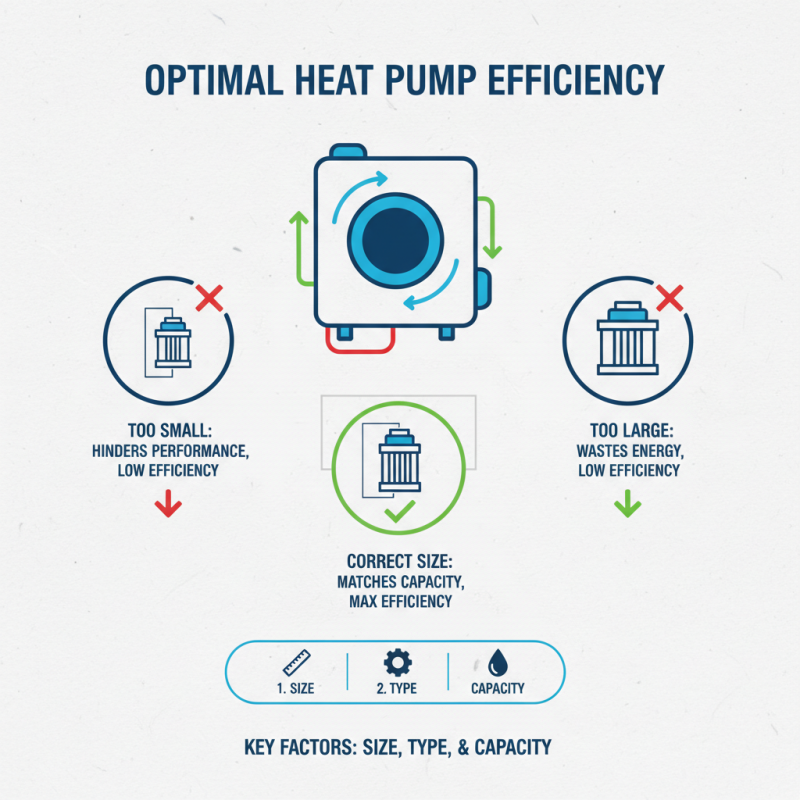

Choosing the right heat pump filter drier is essential for energy efficiency. There are several factors to consider. Start with the size. The drier must match your heat pump’s capacity. A drier that is too small can hinder performance. Conversely, an oversized option might lead to unnecessary energy waste.

Next, look at the material. High-quality materials can enhance durability. The filter drier should be resistant to corrosion. This aspect influences how long the part lasts. A well-made filter drier minimizes the risk of leaks. Leaks lead to energy loss. This can become costly over time.

Another crucial factor is the flow rate. The drier's flow rate must align with your system’s requirements. An incompatible flow rate can restrict circulation. This directly affects the heat pump's efficiency. Regular maintenance and timely replacements are also vital. Over time, a clogged filter drier reduces efficiency. This is a common oversight that can be easily remedied. Pay attention to these details for improved energy use.

When it comes to heating and cooling systems, using the right filter drier is crucial. A quality filter drier effectively removes moisture and contaminants from the refrigerant. This process helps maintain the system’s efficiency. A clogged or inadequate filter can lead to energy loss. Frequent breakdowns and increased energy bills are more likely without proper filtration.

Selecting an appropriate filter drier can significantly enhance energy efficiency. With a clean system, the compressor runs smoothly. There’s less strain on the parts, which reduces energy consumption. In fact, regular maintenance including filter drier checks can prolong the system’s lifespan. Sometimes, overlooked components cause bigger issues. It's essential to reflect on these details.

Many homeowners neglect their filter drier status. This oversight can result in costly repairs. Even a small investment in the right filter drier pays off in the long run. Proper filtration boosts overall system performance, leading to energy savings. The benefits are clear, yet often ignored. Understanding this can help make better choices.

Heat pump filter driers play a crucial role in energy efficiency. Regular maintenance can significantly enhance their performance. A clean filter ensures optimal airflow. When airflow is restricted, the system works harder. This can lead to increased energy bills and shorter equipment lifespan.

Check your filter drier frequently. Look for any signs of dirt or blockage. Replace filters as recommended, typically every few months. Over time, moisture can accumulate too. Use a refrigerant gauge to check levels regularly. This can help in identifying issues early on.

Pay attention to unusual noises or a drop in efficiency. These signs can indicate potential problems. It's easy to overlook small changes, but they matter. Consistent inspection can save you money and headaches later. Make maintenance a routine. It’s an investment in longevity and improved performance.