Choosing the best freezer motor can significantly enhance your cooling solutions. A reliable freezer motor ensures optimal performance, keeping your food fresh and safe. The right motor can reduce energy consumption, thus lowering your utility bills.

Many options exist on the market today, each with unique features. However, not every motor is built equally. Some may lack durability or efficiency. It's essential to consider factors like horsepower, noise level, and warranty.

Investing time in research can make a difference. Look for reviews that provide insights into real user experiences. A good motor doesn't only serve its purpose. It can improve the overall functionality of your freezer. Reflecting on these elements will lead you to make an informed decision about your freezer motor selection.

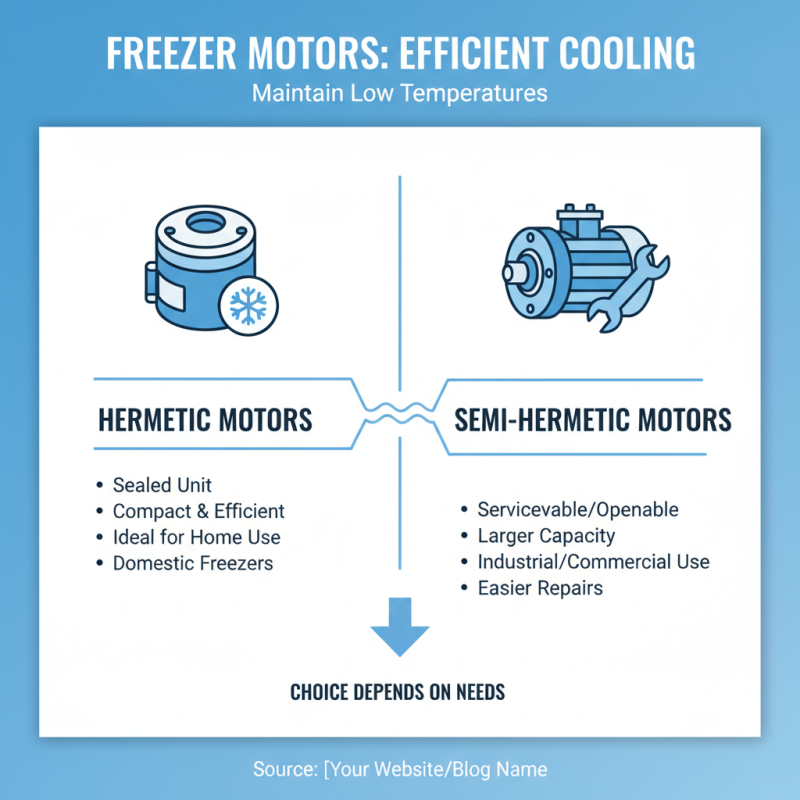

Freezer motors play a crucial role in efficient cooling. They are responsible for maintaining low temperatures within freezers. Understanding the different types can help you choose the best one for your needs. The two main types are hermetic and semi-hermetic motors. Hermetic motors are sealed and often used in domestic freezers. They are compact and efficient, ideal for home use.

On the other hand, semi-hermetic motors are more versatile. They allow for repairs and maintenance, which can be beneficial in commercial settings. The choice between them often depends on the application. A hermetic motor might be great for small-scale use, but larger setups might require the durability of a semi-hermetic option.

Not all freezer motors are created equal. Some models may struggle in extreme conditions. Users may encounter issues like inconsistent cooling. This can lead to spoiled food and increased energy costs. Regular maintenance helps, but not everyone knows the signs to watch for. A careful evaluation of your needs will guide you in making a choice that combines efficiency and functionality.

When selecting the best freezer motor for efficient cooling, there are key features to consider. Power efficiency is crucial. A motor with low wattage can significantly reduce energy consumption. Look for models that offer high cooling capacity while maintaining a compact design. Noise levels also matter; quieter motors provide a more comfortable environment.

Another important aspect is durability. Freezer motors should withstand various temperatures. Corrosion resistance is a key indicator of a motor’s longevity. Check the materials used in the motor's construction. Quality components can prevent unexpected breakdowns, which can be frustrating.

Consider functionalities like variable speed control. This allows adjustments based on the cooling requirements. It enhances efficiency and could extend the motor's lifespan. It’s worth noting that some motors may not perform well under heavy loads. This can lead to overheating. Finding a balance between performance and reliability is essential for optimal cooling solutions.

When it comes to freezer motors, efficiency is key. Various brands prioritize reliable cooling solutions that won’t break the bank. An efficient motor not only minimizes energy consumption but also enhances the overall performance of your freezer. A well-functioning motor maintains consistent temperatures, crucial for preserving food quality.

Choosing the right brand can be tricky. Some offer budget-friendly models that perform well, while others may overpromise and underdeliver. It's important to consider factors like energy efficiency ratings and noise levels. Paying attention to user reviews can help identify potential issues. Slight fluctuations in temperature or noise can indicate deeper problems down the line.

Consumers sometimes overlook the importance of quality control. Motors might appear perfect but can fail in high-demand situations. Regular maintenance is needed to ensure long-lasting performance. Investing time in research can save headaches later. Thoughtful selections lead to better cooling solutions, enhancing freezer reliability.

| Motor Type | Power (W) | Efficiency Rating | Price (USD) |

|---|---|---|---|

| Hermetic Compressor | 150 | A+ | 120 |

| Fan Motor | 75 | A | 60 |

| Capacitor Start Motor | 100 | B | 80 |

| Inverter Compressor | 200 | A+++ | 200 |

| Brushless DC Motor | 50 | A++ | 90 |

When installing a freezer motor, attention to detail is crucial. Begin by ensuring that your workspace is clean and organized. This prevents dust and debris from interfering with the installation process. Gather all necessary tools beforehand to avoid interruptions. A checklist can be useful here, as missing tools may delay the project.

Proper placement of the motor is vital for efficiency. Ensure that it is installed close to the compressor and within the manufacturer’s recommended distance. This can help with effective cooling and minimize energy consumption. Be mindful of wiring as well; poorly connected wires can lead to performance issues. Pay close attention to airflow. Obstructions can cause overheating, which may harm the motor over time.

Testing the motor after installation is often overlooked. Make sure to run it for a while and check for unusual noises or vibrations. If something seems off, don’t ignore it. Address these issues promptly to avoid bigger problems down the road. Regular maintenance checks can help catch potential failures early, ensuring longevity and optimal performance.

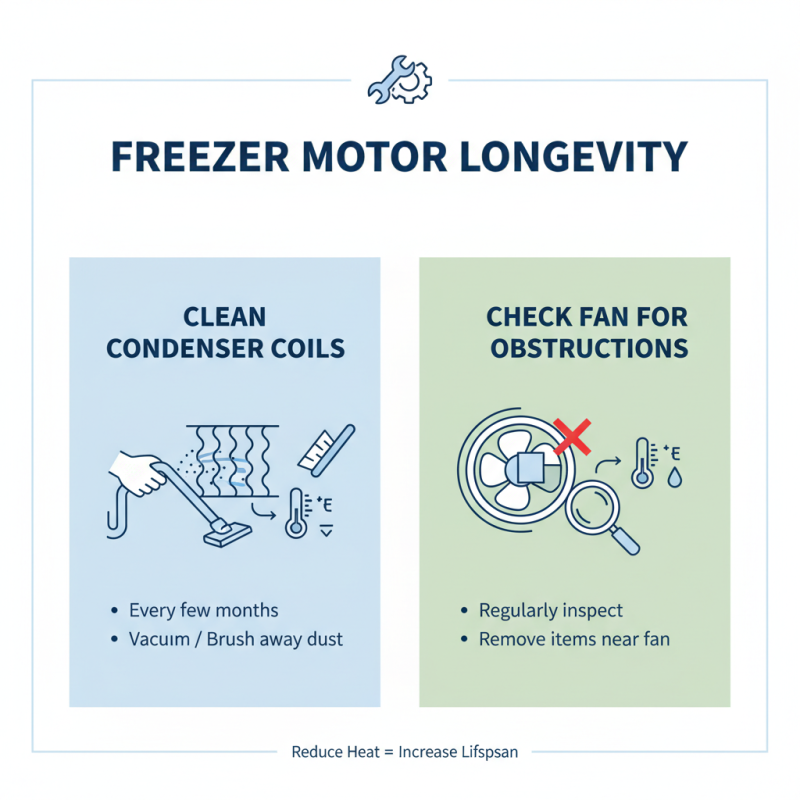

To ensure the longevity of your freezer motor, regular maintenance is essential. Start by cleaning the condenser coils every few months. Dust and debris can accumulate, restricting airflow and causing inefficiency. A vacuum cleaner or a brush works wonders. Regularly check for obstructions around the motor's fan. Even small items can lead to overheating.

Another crucial practice is monitoring the motor's operating temperature. If it feels excessively hot, this could indicate a problem. You might need to investigate further. In addition, inspect the electrical connections. Loose wires can cause short circuits or motor failure. Having a professional technician assess these components can save headaches later on.

Lubrication is also vital. Moving parts require it to function smoothly. Use the appropriate lubricant as suggested in the user manual. Ignoring this step may lead to premature wear and additional repair costs. Lastly, don’t forget about routine inspections of seals and gaskets. They prevent cold air from escaping, ensuring efficiency. Be vigilant, as failing to address small issues can lead to bigger problems.