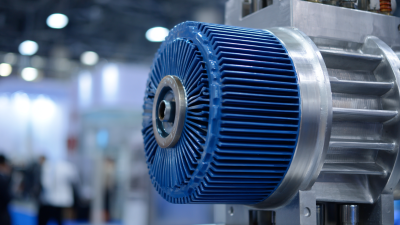

In the evolving field of HVAC technology, the significance of the condenser motor cannot be overstated. Industry expert John Smith once said, "Efficient condenser motors breathe new life into cooling systems." As we look toward 2026, understanding the features and benefits of condenser motors becomes crucial for both manufacturers and consumers.

These motors are the heart of many cooling systems. They enhance energy efficiency and performance. However, not all motors are created equal. Some experience issues with noise and reliability. Awareness of these pitfalls is essential when selecting the right condenser motor.

Innovative features like variable speed and smart technology are on the rise. They promise to improve user experience significantly. But there's a learning curve; not all users fully grasp these advancements. As we prepare for the future, it's important to reflect on how we can harness the full potential of condenser motors. Balancing innovation with real-world application will drive success in the HVAC industry.

The 2026 top condenser motors come with several key features that enhance performance. These motors boast improved energy efficiency, helping reduce electricity costs. Their compact designs allow for easy installation in tight spaces. Additionally, quieter operation ensures minimal noise disruption. Another important feature is durability. The latest models use high-quality materials, ensuring longevity and reliability. This means less frequent replacements, which can be a hassle. Moreover, their advanced cooling technology maintains optimal temperature, preventing overheating during prolonged use. However, not all features may be perfect. Some users report compatibility issues with older systems. It's important to assess your specific needs before making a decision. Additionally, while energy-efficient, initial costs can be higher. Careful consideration is needed to balance short-term expenses against long-term savings. Understanding these factors will lead to better choices.

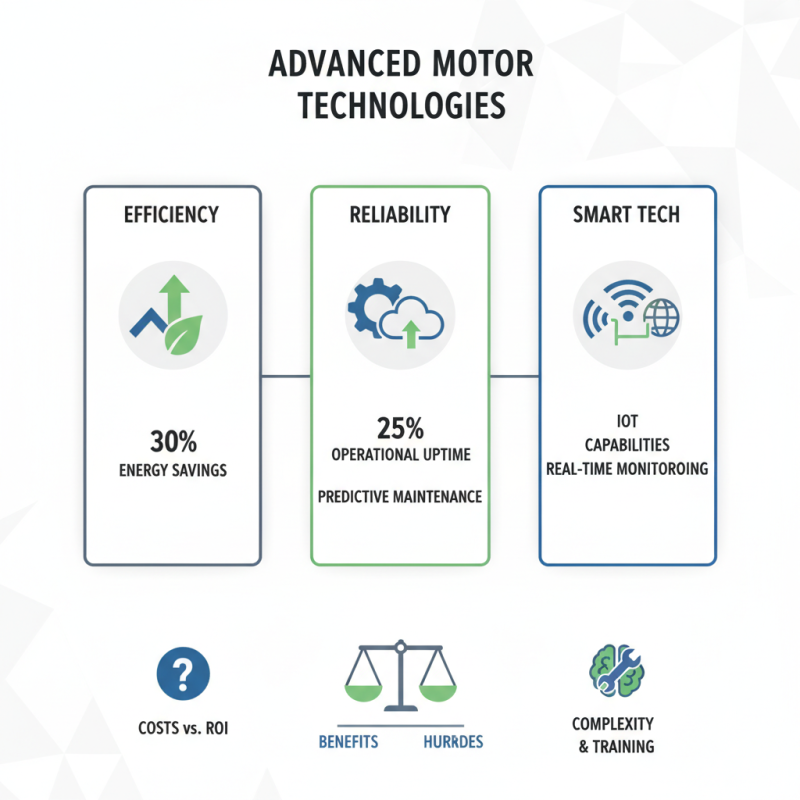

Advanced motor technologies are transforming the landscape of condenser motors. These innovations bring notable benefits that enhance performance and efficiency. Reports show that motors with high efficiency can reduce energy consumption by up to 30%. Such savings are crucial for industries looking to cut operating costs while remaining environmentally friendly. The integration of smart technology is another key aspect. Motors equipped with IoT capabilities enable monitoring in real-time. This can lead to predictive maintenance, minimizing downtime. A recent study highlighted that businesses leveraging these smart motors saw a 25% increase in operational uptime. However, not all facilities have adopted these technologies, raising questions about accessibility and training. Efficiency is impressive, but challenges remain. While advanced motors are more powerful, they can be complex to operate. Staff training is often necessary, which can incur additional costs. Some businesses hesitate to invest, worried about the return on investment. It's crucial to evaluate both benefits and potential hurdles when considering an upgrade. The balance between costs and efficiency improvements deserves careful consideration.

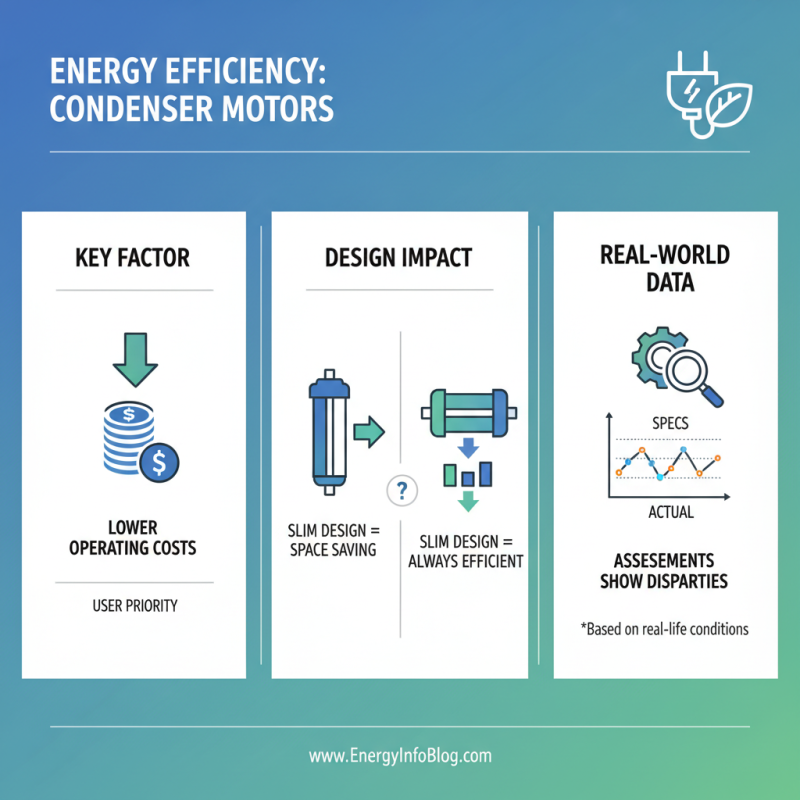

Energy efficiency is a crucial factor when evaluating condenser motors. Many users prioritize this feature. Higher efficiency often leads to lower operating costs. It’s important to understand how different designs impact energy usage. Slim motors might save space, but they can sometimes sacrifice efficiency. Regular assessments in real-life conditions reveal disparities not always highlighted in specifications.

Another aspect to consider is the materials used in manufacturing. Some motors use advanced materials that enhance performance. However, these materials can increase production costs. Are the benefits worth the price? This question often arises during purchasing decisions. Additionally, some motors may have more complicated designs. They can be tougher to maintain, which can lead to higher long-term costs.

In comparing various models, one must consider real-world application scenarios. A motor might perform well in ideal tests but struggle in daily usage. Efficiency ratings don’t always reflect practical experiences. Users should seek reviews and case studies from similar environments. Before making a decision, reflecting on both efficiency and usability can guide better choices.

Noise reduction is a critical feature in modern condenser motors. The noise levels produced by these motors can significantly affect the overall user experience. A quieter motor allows for a more comfortable environment. This is especially important in residential or office settings.

Many manufacturers focus on engineering designs that minimize vibrations. This leads to reduced sound output while maintaining efficiency. Advanced noise reduction features often include improved insulation materials. These materials absorb sound waves before they escape. Additionally, strategic placement of components can prevent noise from amplifying.

However, achieving the perfect balance between noise control and performance can be challenging. Some models may sacrifice efficiency for lower noise levels, which is not ideal.

Users often overlook the impact of these noise reduction features. A quieter motor may seem like a luxury, but it enhances daily life. It's essential to reflect on how sound affects our well-being. The importance of these features should not be underestimated. Investing in a motor with noise reduction can lead to long-term satisfaction. In some cases, it might be worth compromising on other features for reduced noise output.

The future of condenser motor design is promising. Innovations focus on energy efficiency and compactness. Engineers aim to reduce energy consumption without sacrificing performance. New materials will play a crucial role in weight reduction. Lighter motors can enhance installation options in tight spaces.

Smart technology is another significant trend. Integrating IoT capabilities into condenser motors may allow for real-time monitoring. Users could receive alerts on performance issues before they escalate. However, security concerns arise with increased connectivity. Manufacturers must address potential vulnerabilities in these smart systems.

Sustainable practices are also gaining traction. Eco-friendly materials and production methods are becoming a priority. Some designs may feature recyclable components. Despite advancements, the industry must grapple with balancing innovation and cost. High-quality components can be expensive, raising questions about accessibility for all consumers.